Novel graphite corrugated heat exchange plate heat exchanger

A technology of graphite heat exchange and heat exchanger, which is applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of large thermal resistance, low heat transfer efficiency, small thermal resistance, etc., to reduce the interface Liquid film thermal resistance, not easy to deposit and block, excellent heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as Figure 4 to Figure 6 As shown, a single-flow graphite corrugated heat exchanger includes a first cover plate 1, a first head 2, a gasket 3, a graphite heat exchange plate 4, a second head 5, and a second cover plate 6 and fasteners 7, the first cover plate 1 and the second cover plate 6 are symmetrically arranged, and a multi-layer graphite heat exchange plate 4 is stacked between the first cover plate 1 and the second cover plate 6, and the two The graphite heat exchange plate 4 at the end and the end cover plate are respectively provided with a first head 2 and a second head 5, and the graphite heat exchange plates 4 of each layer are separated by a gasket 3, and the multi-layer graphite heat exchange plate The thermal plate 4 is fixed through by fasteners 7 .

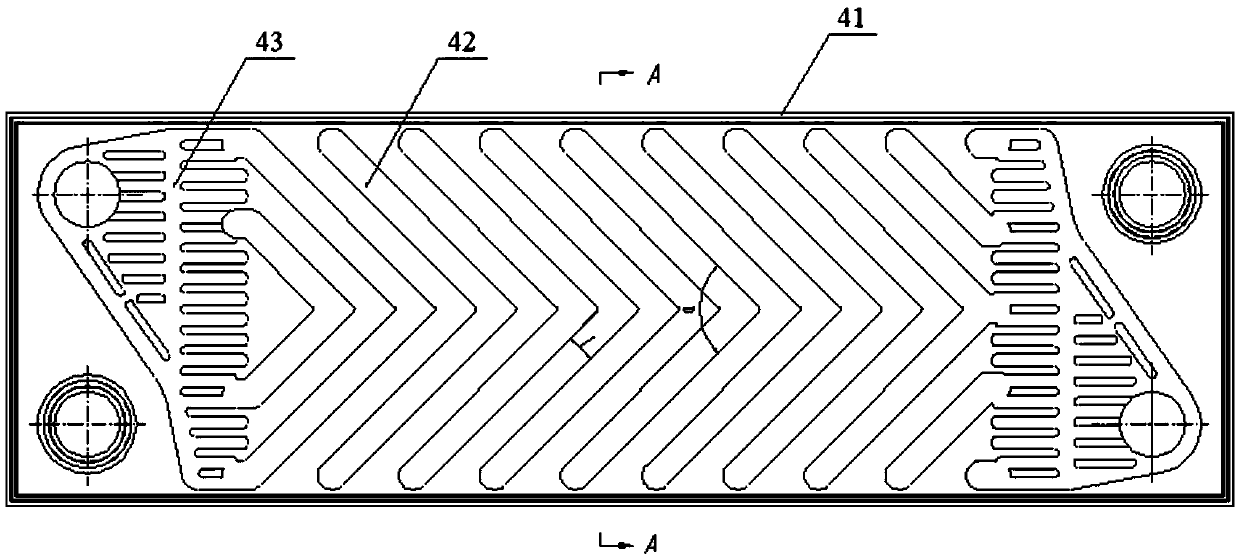

[0033] In this example, if figure 1 and figure 2 As shown, the graphite heat exchange plate 4 includes a frame 41, the frame 41 is provided with a heat exchange area 42 and a liquid distribution ...

Embodiment 2

[0041] Such as Figure 7 to Figure 9 As shown, a multi-process graphite corrugated heat exchanger includes a first cover plate 1, a first head 2, a gasket 3, a graphite heat exchange plate 4, a second head 5, and a second cover plate 6. Fasteners 7 and baffles 12, the first cover plate 1 and the second cover plate 6 are symmetrically arranged, and multi-layer graphite replacement plates are stacked between the first cover plate 1 and the second cover plate 6 The heat plate 4, the graphite heat exchange plate 4 at both ends and the end cover plate are respectively provided with a first head 2 and a second head 5, and the graphite heat exchange plates 4 of each layer are separated by a gasket 3 The middle part of the multilayer graphite heat exchange plate 4 is provided with a baffle plate 12 for baffle, and the multilayer graphite heat exchange plate 4 is penetrated and fixed by fasteners 7 .

[0042] In this example, if figure 1 and figure 2 As shown, the graphite heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com