Passivant for nickel plating and nickel plating passivation method

A passivating agent and nickel plating technology, which is applied in the field of passivating agent for nickel plating and nickel plating passivation, can solve the problems of long passivation time, high production cost, limited application range, etc., and achieve good salt spray effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

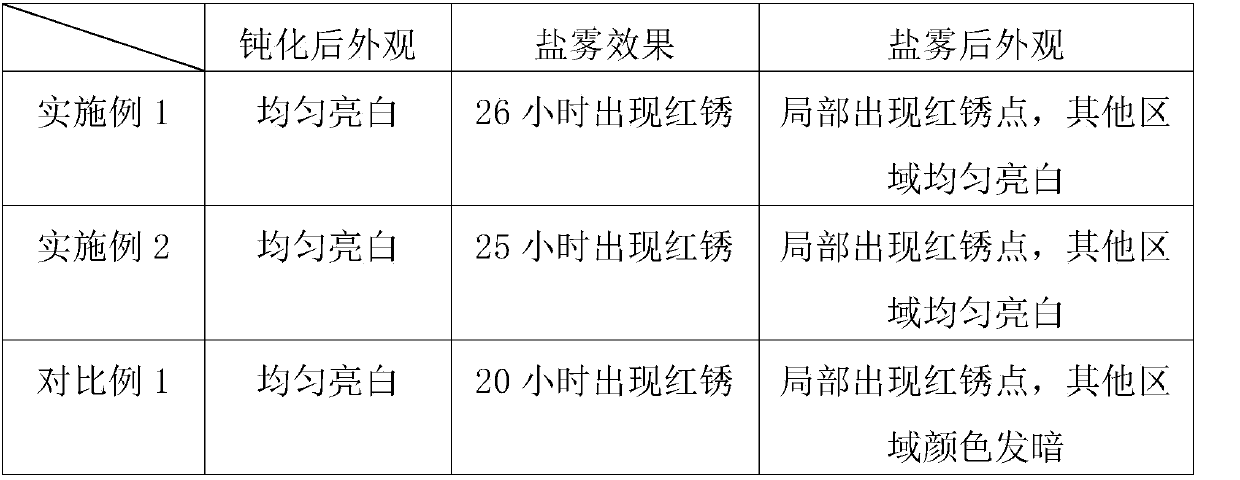

Examples

Embodiment 1

[0038] Passivator formula ratio: vegetable oleic acid 0.6ml / L, absolute ethanol 0.6ml / L, triethanolamine 0.6ml / L, and the balance is water.

[0039] Mix the above formula into a passivator and set aside.

[0040] Ultrasonic degreasing of iron parts for 10 minutes, washing with water for 3 times, derusting and activation with 20-30% hydrochloric acid, washing with water for 3 times, electroless nickel plating with medium phosphorus for 0 minutes, nickel plating temperature at 90 degrees, pH value 4.5.

[0041] Soak the nickel-plated iron piece in a passivating agent, the soaking temperature is 60°C, and the soaking time is 2-4 minutes. The workpiece after soaking is washed with water, then washed with pure hot water, and then dried.

Embodiment 2

[0043] Passivator formula ratio: vegetable oleic acid 0.6ml / L, absolute ethanol 0.8ml / L, triethanolamine 0.6ml / L, and the balance is water.

[0044] Mix the above formula into a passivator and set aside.

[0045] Ultrasonic degreasing of iron parts for 10 minutes, washing with water for 3 times, then 20-30% hydrochloric acid for derusting and activation, washing with water for 3 times, electroless nickel plating with medium phosphorus for 30 minutes, nickel plating temperature is 90 degrees, pH value is 4.5.

[0046] Soak the nickel-plated iron piece in a passivating agent, the soaking temperature is 60°C, and the soaking time is 2-4 minutes. The workpiece after soaking is washed with water, then washed with pure hot water, and then dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com