Oil-water separation device for vacuum oil purifier

A vacuum oil purifier, water and oil separation technology, applied in the directions of filtration separation, separation method, chemical instrument and method, etc., can solve the problems of easy sticking oil stains on heating devices, must be cleaned or replaced, reduce heating effect, etc., and achieve high hardness , Improve the utilization rate and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

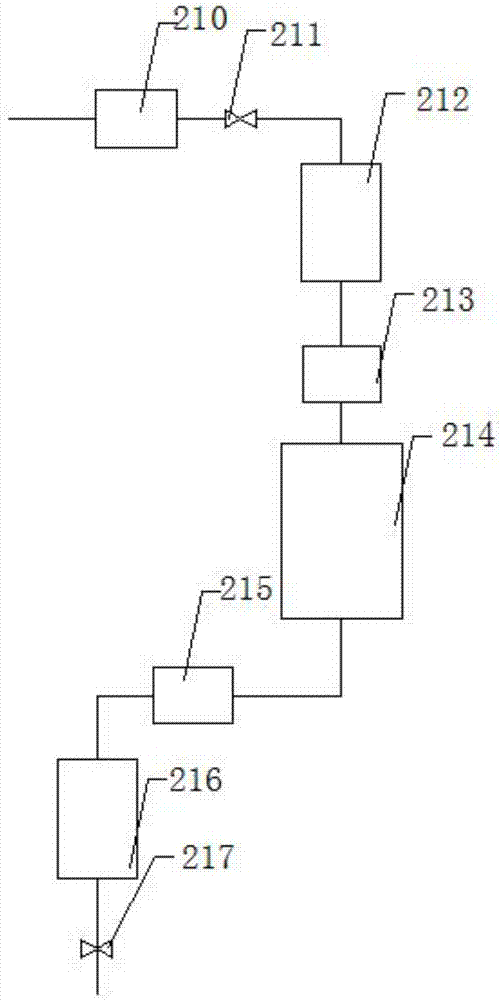

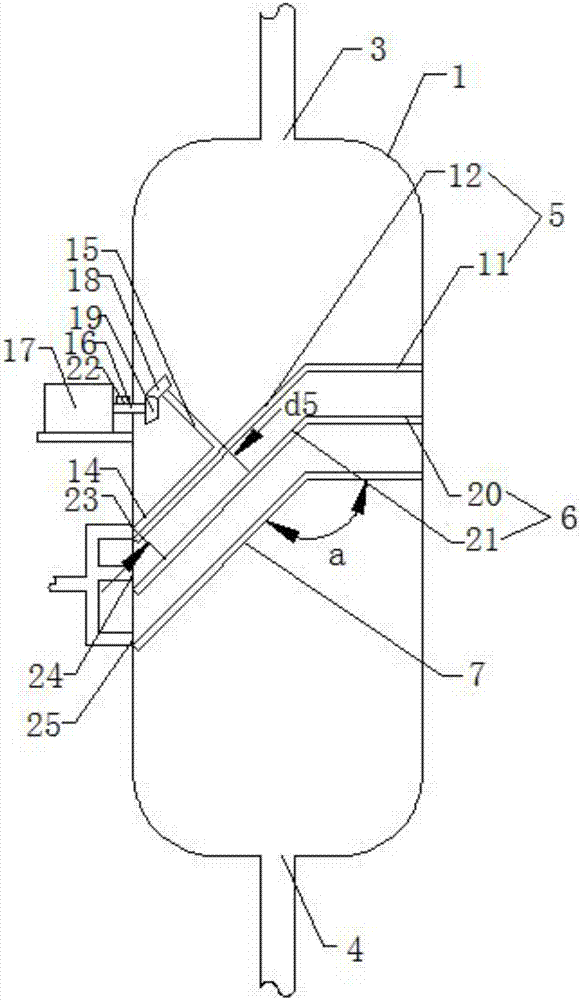

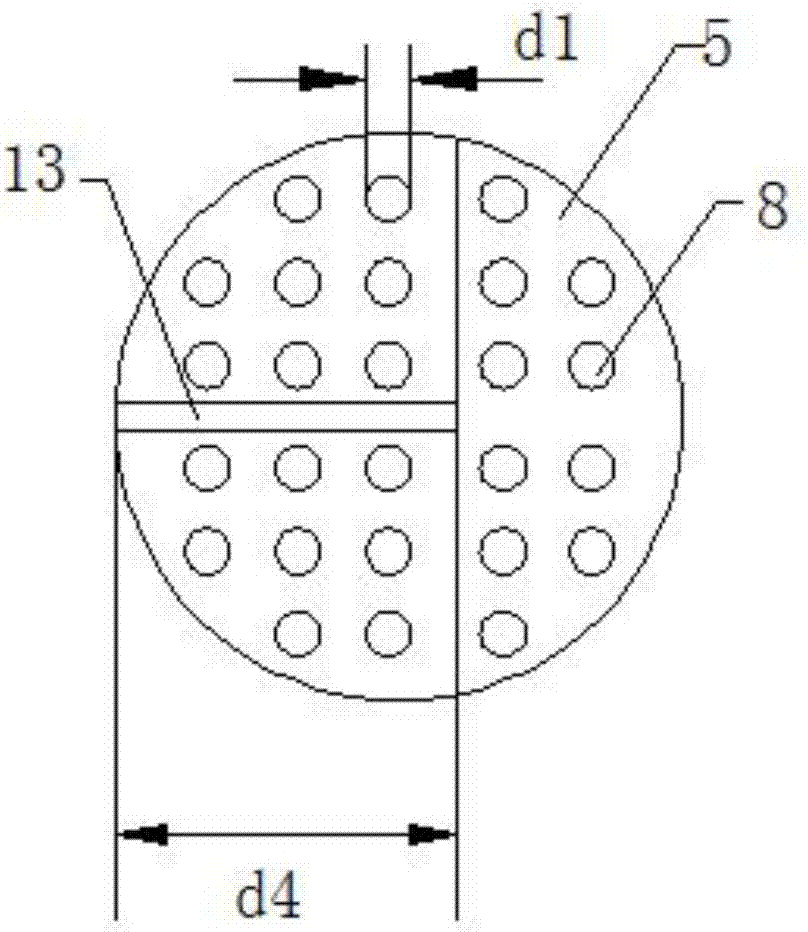

[0031] As shown in the figure, a water-oil separation device for a vacuum oil purifier includes an oil inlet pump, an oil inlet valve, a coarse filter, a heater, a vacuum tank, an oil outlet pump, a fine filter, and an oil outlet valve. One end of the valve is connected to the oil inlet pump through pipelines, the other end is connected to the coarse filter through pipelines, the coarse filter is connected to the heater through pipelines, the heater is connected to the vacuum tank through pipelines, the vacuum tank is connected to the oil outlet pump through pipelines, and the oil outlet pump is connected to the fine filter The oil outlet pump and the oil outlet valve are connected by pipelines, the vacuum tank is provided with an atomizer, the heater is provided with a heating device, and the fine filter is provided with a fine filter tank;

[0032]The heating device includes a first heating tube and a second heating tube, the first heating tube is a U-shaped structure, the fi...

Embodiment 2

[0044] It is basically the same as Example 1, the difference is:

[0045] The preparation method of described oil-proof coating is as follows:

[0046] Step (1) Weigh raw materials: by weight, weigh 20 parts of nano-titanium oxide, 20 parts of nano-alumina, 20 parts of nano-silicon oxide, 10 parts of perhydropolysilazane, 5 parts of propylene powder, pulverized coal 5 parts of ash, 5 parts of talcum powder, 10 parts of absolute ethanol, 20 parts of acetone, 30 parts of isopropanol, 10 parts of phenyltrichlorosilane, and 10 parts of silane coupling agent;

[0047] Step (2) Initial mixing: Add nano-titanium oxide, nano-alumina, nano-silicon oxide, dispersant, and organic solvent into the reaction kettle, perform ultrasonic treatment first, and then stir and mix after ultrasonic dispersion. The stirring time is 2 hours, and the stirring temperature is 120°, stirring speed 500r / min;

[0048] Step (3) remixing: Add perhydropolysilazane, filler, and silicone resin into the reactio...

Embodiment 3

[0051] It is basically the same as Example 1, the difference is:

[0052] The preparation method of described oil-proof coating is as follows:

[0053] Step (1) Weigh raw materials: by weight, weigh 10 parts of nano-titanium oxide, 20 parts of nano-alumina, 5 parts of nano-silicon oxide, 5 parts of perhydropolysilazane, 5 parts of propylene powder, kaolin powder 5 parts, 5 parts of fly ash, 5 parts of talcum powder, 10 parts of absolute ethanol, 20 parts of acetone, 30 parts of isopropanol, 10 parts of phenyltrichlorosilane, 10 parts of silane coupling agent;

[0054] Step (2) Initial mixing: Add nano-titanium oxide, nano-alumina, nano-silicon oxide, dispersant, and organic solvent into the reaction kettle, perform ultrasonic treatment first, and then stir and mix after ultrasonic dispersion. Stirring time is 1h, stirring temperature 120°, stirring speed 500r / min;

[0055] Step (3) remixing: Add perhydropolysilazane, filler, and silicone resin into the reaction kettle, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com