Sulphate trivalent chromium electroplating pollution as well as preparation process thereof and electroplating process thereof

A technology of production process and electroplating process, which is applied in the fields of sulfate trivalent chromium electroplating solution and its production process and electroplating process, and can solve the problems of uneven color plating of workpieces, large power consumption, and slow deposition rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

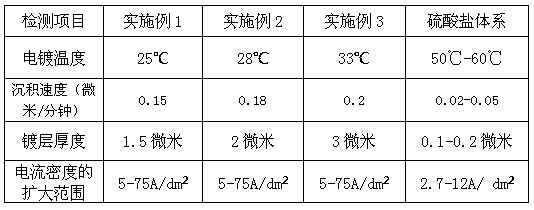

Embodiment 1

[0039] A sulfate trivalent chromium electroplating solution, which comprises the following components by weight: conductive salt 30%, A preparation 20%, B preparation 6%, C preparation 0.5%, D preparation 1%, wetting agent 0.3%, all the other are pure water.

[0040] The conductive salt is composed of 46% potassium sulfate, 15% sodium sulfate, 8% ammonium sulfate, 9% magnesium sulfate and 22% boric acid in weight ratio.

[0041] Described A preparation comprises following weight proportion composition: 45% chromium sulfate, the complexing agent of 16%, all the other are the pure water that makes A preparation usefulness;

[0042] The B preparation is a mixture of formic acid, glycolic acid, malic acid, tartaric acid and nitrilotriacetic acid with a weight ratio of 10-50%, and the rest is pure water for making the B preparation.

[0043] The C preparation includes 2-20% thiourea by weight, and the rest is pure water for preparing the C preparation. The thiourea can be thioure...

Embodiment 2

[0047] A kind of sulfate trivalent chromium electroplating solution, it comprises following composition by weight ratio: conductive salt 35%, A preparation 16%, B preparation 8%, C preparation 1.5%, D preparation 1.5%, wetting agent 0.5%, all the other are pure water.

[0048] The conductive salt is composed of 42% potassium sulfate, 19% sodium sulfate, 6% ammonium sulfate, 5% magnesium sulfate and 28% boric acid by weight.

[0049] The A preparation includes the following components by weight: 38% chromium sulfate, 19% complexing agent, and the rest is pure water for making the A preparation.

[0050] The B preparation includes a mixture of lactic acid, malic acid and nitrilotriacetic acid with a weight ratio of 10-50%, and the rest is pure water for making the B preparation.

[0051] The C preparation includes a mixture of thiourea and sodium thiosulfate with a weight ratio of 2-20%, and the rest is pure water for making the C preparation.

[0052] The D preparation includ...

Embodiment 3

[0055] A kind of sulfate trivalent chromium electroplating solution, it comprises following composition by weight ratio: conductive salt 23%, A preparation 25%, B preparation 10%, C preparation 2%, D preparation 0.5%, wetting agent 0.6%, all the other are pure water.

[0056] The conductive salt is composed of 38% potassium sulfate, 20% sodium sulfate, 9% ammonium sulfate, 10% magnesium sulfate and 23% boric acid by weight.

[0057] Described A preparation comprises following weight proportion composition: 32% chromium sulfate, 12% complexing agent, all the other are the pure water that makes A preparation usefulness;

[0058] The B preparation includes a mixture of lactic acid, malic acid, tartaric acid and nitrilotriacetic acid with a weight ratio of 10-50%, and the rest is pure water for making the B preparation.

[0059] The C preparation includes 2-20% sodium thiosulfate by weight, and the rest is pure water for preparing the C preparation.

[0060] The D preparation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com