Mycobacterium fortuitum capable of effectively producing 9alpha-OH-AD and application thereof

A technology of Mycobacterium fortuitousus, -OH-AD, which is applied in the direction of bacteria, fermentation, and microbial-based methods, can solve the problems of up to 336 hours of transformation cycle and low conversion rate of substrates, and achieve good industrial application prospects, The effect of reduced conversion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

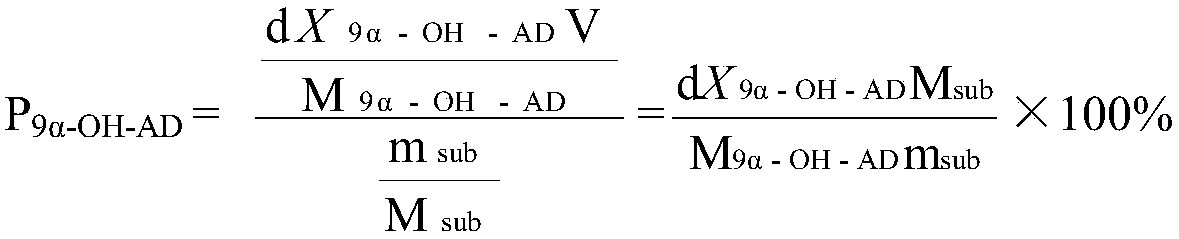

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Mutagenesis screening of ARL-91

[0023] ARTP and LiCl complex mutagenesis of Mycobacterium fortuitum:

[0024] (1) wash the slant seeds of starting bacterial strain Mycobacterium fortuitum (Mycobacterium fortuitum) (this bacterial strain is preserved by applicant's laboratory) with 0.5% Tween 80 sterile aqueous solution, make thalline OD 600 The value is controlled at 1.0±0.2. Inoculate into 50mL seed culture medium (same as Example 2) with 3% inoculum size, cultivate at 30°C and 200r / min until logarithmic growth phase (22-24h);

[0025] (2) ARTP mutagenesis

[0026] Adjusting step (1) to prepare the starting strain cultivated into OD 600 = 0.6~0.8 bacteria suspension, use a pipette gun to draw 10 μL on the mutagenesis slide, carry out ARTP mutagenesis, the mutagenesis time is 60s, wash the bacteria on the mutagenesis slide to get the bacteria suspension, for the mutagenesis The bacterial suspension was serially diluted, and 100 μL was spread on the agar...

Embodiment 2

[0033] Example 2: Fermentative production of 9α-OH-AD by Mycobacterium fortuitousus

[0034] Experimental strains: ARL-91 and starting strains;

[0035] (1) Seed cultivation

[0036] Take the fresh ARL-91 strain and one slant of the starting strain that have been cultivated for 2 to 3 days, and wash the slant seeds with 0.5% Tween80 sterile aqueous solution to make the bacteria OD 600 The value is controlled at 1.0±0.2. Inoculate into 50mL seed medium with 3% inoculum amount, cultivate at 30°C and 200r / min until logarithmic growth phase (22-24h).

[0037] The seed medium components are as follows: diammonium hydrogen phosphate 1.5g / L, yeast powder 9g / L, glycerol 10g / L, sodium dihydrogen phosphate 0.5g / L, disodium hydrogen phosphate 0.5g / L, Tween 80 0.5g / L, adjust the pH to 7.3;

[0038] (2) Fermentation culture

[0039] The seed solution was inserted into the fermentation medium with an inoculation amount of 8%, and phytosterol with a final concentration of 10g / L was adde...

Embodiment 3

[0047] Example 3 Fermentation of ARL-91 to produce 9α-OH-AD

[0048] (1) The production strain is ARL-91, and the seed culture is the same as in Example 1;

[0049] (2) Fermentation culture: insert the seed liquid into the fermentation medium according to the inoculation amount of 10%, add phytosterols with a final concentration of 5g / L in the fermentation medium, and ferment at 28~30°C and 160r / min After 48h, the production rate of 9α-OH-AD reached 96.2% after the fermentation.

[0050] The composition of the fermentation medium is as follows: ammonium sulfate 2.0g / L, urea 0.2g / L, sodium dihydrogen phosphate 1.0g / L, disodium hydrogen phosphate 0.5g / L, Tween 80 0.3g / L, glycerin 8g / L L. Phytosterol 5g / L, methyl-β-cyclodextrin 15.8g / L, pH 7.3, sterilized at 120-122°C for 20min under a pressure of 0.1-0.15mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com