Method for preparing silica nanoparticle-graphene oxide-plant fiber compound

A nanoparticle and silica technology, applied in the field of building materials, can solve the problems of damage to fiber structure, decrease in fiber strength and toughness, etc., and achieve the effects of simple process flow, improved adhesion and reduced erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

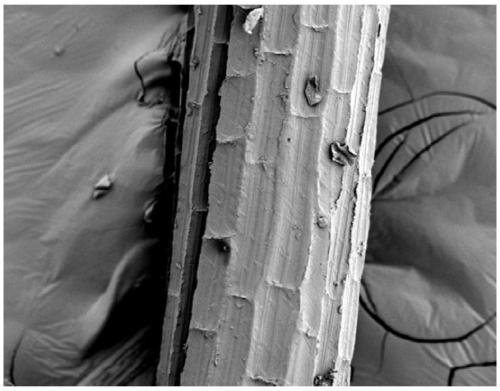

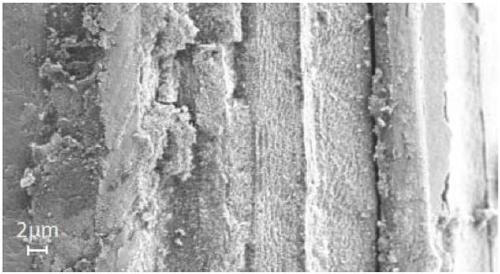

[0027] Taking sisal fiber as an example, silica nanoparticles-graphene oxide-sisal fiber composite was prepared.

[0028] (1) Pretreatment of sisal fibers: cut the natural sisal fibers into short fibers with a length of 30 mm, wash the mud sand and debris on the surface with clear water, and dry them in a blast dryer at 60°C. Then soak in 0.15mol / L NaOH solution for 30min. After alkali treatment, the sisal fiber is repeatedly washed with clean water to neutrality, and dried in a blast dryer at 60°C.

[0029] (2) Graphene oxide was prepared by an improved Hummers method, and configured into a graphene oxide aqueous solution with a concentration of 2 mg / ml.

[0030] (3) Preparation of silica nanoparticle dispersion: 5g of silica nanoparticles and 5g of polycarboxylate superplasticizer were added to the deionized water in 200g (2), after high-speed electromagnetic stirring for 30min, ultrasonic oscillation (600W ) 1.5h to obtain a uniformly dispersed silica nanoparticle dispers...

Embodiment 2

[0034] Taking sisal fiber as an example, silica nanoparticles-sisal fiber composites were prepared.

[0035] (1) Pretreatment of sisal fibers: cut the natural sisal fibers into short fibers with a length of 50 mm, wash the silt and debris on the surface with water, and dry them in a blast dryer at 60°C. Then soak in 0.1mol / L NaOH solution for 1h. After alkali treatment, the sisal fiber is repeatedly washed with clean water to neutrality, and dried in a blast dryer at 60°C.

[0036] (2) Graphene oxide was prepared by an improved Hummers method, and configured into a graphene oxide aqueous solution with a concentration of 1 mg / ml.

[0037] (3) Preparation of silica nanoparticle dispersion: add 2g of silica nanoparticles and 0.2g of polycarboxylate superplasticizer to 200g of the graphene oxide dispersion in (2), and after high-speed electromagnetic stirring for 10min, Ultrasonic oscillation (600W) for 0.5h to obtain a uniformly dispersed silica nanoparticle-graphene oxide disp...

Embodiment 3

[0040] Taking coconut shell fiber as an example, silica nanoparticles-graphene oxide-coir fiber composites were prepared.

[0041] (1) Pretreatment of coconut shell fiber: cut the natural coconut shell fiber into short fibers with a length of 20-30mm, wash the mud sand and debris on the surface with water, and dry it in a blast dryer at 60°C. Then soak in 0.5mol / L NaOH solution for 30min. After the alkali treatment, the coconut shell fiber is repeatedly washed with clean water to neutrality, and dried in a blower dryer at 60°C.

[0042] (2) Graphene oxide was prepared by an improved Hummers method, and configured into a graphene oxide aqueous solution with a concentration of 1 mg / ml.

[0043] (3) Preparation of silica nanoparticle dispersion: add 1g of silica nanoparticles and 2g of polycarboxylate superplasticizer to 200g of the graphene oxide dispersion in (2), and after high-speed electromagnetic stirring for 10min, ultrasonically Oscillate (600W) for 0.5h to obtain a uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com