Preparation method of porous ITO conducting glass

A technology of conductive glass and conductive film, applied in the direction of coating, etc., can solve the problems of danger, small corrosion controllability, pore size and uneven distribution, etc., and achieve the effect of good light transmission and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

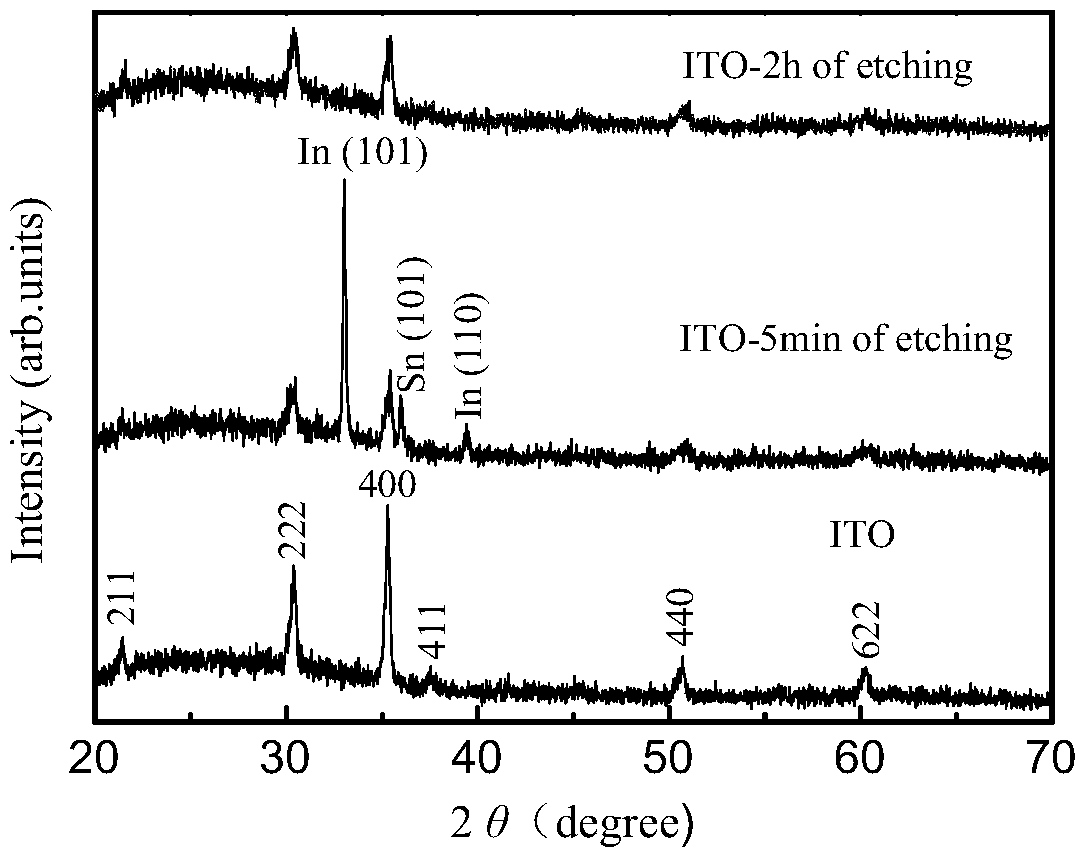

Method used

Image

Examples

Embodiment 1

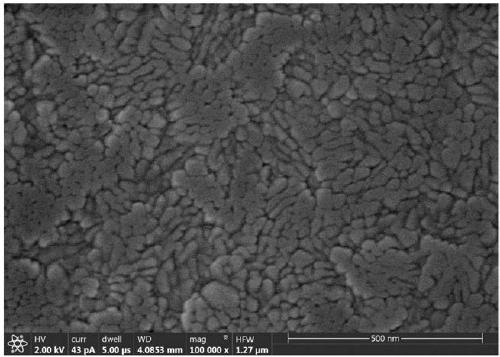

[0033] The average distribution density of pores is about 138 pores / μm 2 , the main pore diameter is 20~50nm ( image 3 ), with a transparency of 89% at 488nm ( Figure 7 ), the surface resistance is the preparation method of the porous ITO conductive glass of 13.4Ω, and concrete operation is as follows:

[0034] Step 1, add 200mg of commercial zinc powder into 10mL of absolute ethanol under stirring, and obtain a zinc powder ethanol suspension with a zinc powder concentration of 20mg / mL after ultrasonication for 5 minutes; dilute concentrated hydrochloric acid to a concentration of 0.08mol / L hydrochloric acid solution, then added in an equal volume of absolute ethanol under stirring to obtain a hydrochloric acid-ethanol mixed solution with a hydrochloric acid concentration of 0.04mol / L (in this mixed solution, the mixing volume ratio of ethanol and hydrochloric acid solution is 1) ;

[0035] Step 2, clean the ITO conductive glass with detergent, dry it at 50°C, and dilute ...

Embodiment 2

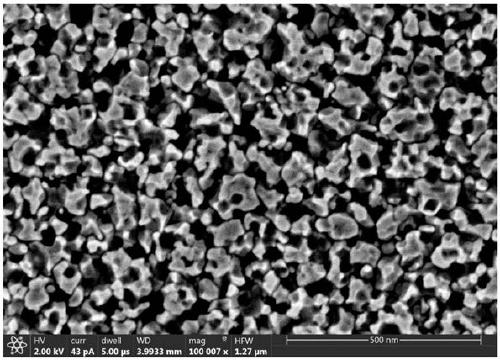

[0039] The average distribution density of pores is about 103 pores / μm 2 , with an average pore size of 72nm ( Figure 4 ), with a transparency of 93% at 488nm ( Figure 7 ), the surface resistance is the preparation method of the porous ITO conductive glass of 18.5 Ω, and concrete operations are as follows:

[0040] Step 1, add 400mg of commercial zinc powder into 10mL of absolute ethanol under stirring, and obtain a zinc powder ethanol suspension with a zinc powder concentration of 40mg / mL after ultrasonication for 5 minutes; dilute concentrated hydrochloric acid to a concentration of 0.08mol / L hydrochloric acid solution, then added in an equal volume of absolute ethanol under stirring to obtain a hydrochloric acid-ethanol mixed solution with a hydrochloric acid concentration of 0.04mol / L (in this mixed solution, the mixing volume ratio of ethanol and hydrochloric acid solution is 1) ;

[0041] Step 2, clean the ITO conductive glass with detergent, dry it at 50°C, and dil...

Embodiment 3

[0044] The average distribution density of pores is 86 pores / μm 2 , with an average pore diameter of 95nm ( Figure 5 ), with a transparency of 89% at 488nm ( Figure 7 ), the surface resistance is the preparation method of the porous ITO conductive glass of 27.8 Ω, and concrete operation is as follows:

[0045] Step 1, add 600mg of commercial zinc powder into 10mL of absolute ethanol under stirring, and obtain a zinc powder ethanol suspension with a zinc powder concentration of 60mg / mL after ultrasonication for 5 minutes; dilute concentrated hydrochloric acid to a concentration of 0.08mol / L hydrochloric acid solution, then added in an equal volume of absolute ethanol under stirring to obtain a hydrochloric acid-ethanol mixed solution with a hydrochloric acid concentration of 0.04mol / L (in this mixed solution, the mixing volume ratio of ethanol and hydrochloric acid solution is 1) ;

[0046] Step 2, clean the ITO conductive glass with detergent, dry it at 50°C, and dilute the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com