A kind of gradient graphene oxide-based structure wave-absorbing material and its preparation method

A graphene-based, wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve the problems of reduced RCS performance of weapons and equipment, low degree of impedance matching of electromagnetic characteristics, complicated preparation process of wave-absorbing materials, etc., so as to break limitations and be easy to industrialize. Production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

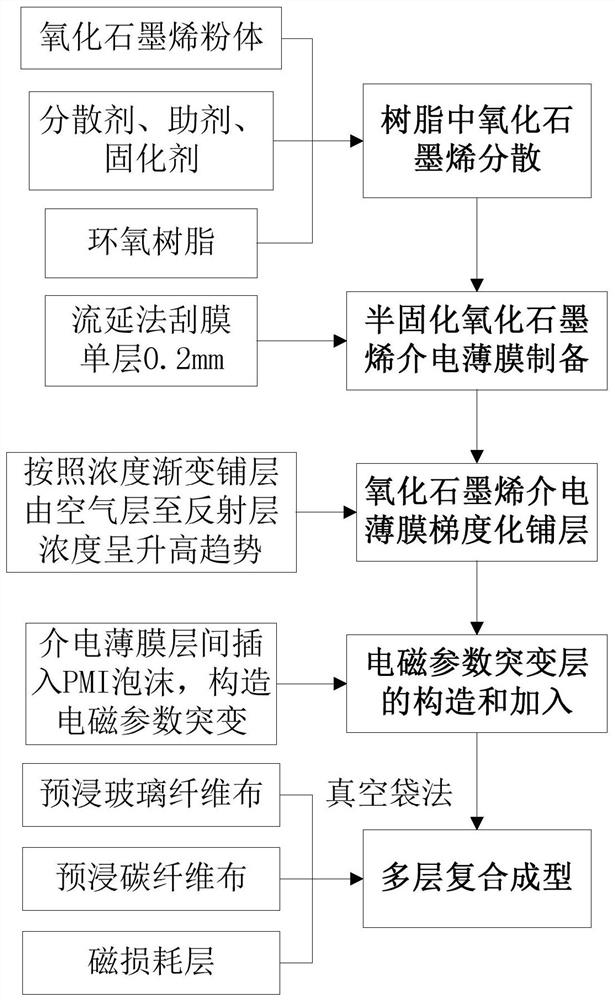

[0034] In a first aspect, the present invention provides a method for preparing a gradient graphene oxide-based structure wave-absorbing material, said method comprising the steps of:

[0035] (1) Graphene oxide, auxiliary agent, curing agent and epoxy resin are formulated into various (multiple parts) mixed slurries with different graphene oxide mass percentages (such as thick graphene oxide mixed with dispersant) slurry).

[0036](2) Casting the various mixed slurries prepared in step (1) on the release paper to form a film respectively by casting method (for example, adopting the casting method to scrape-coat the mixed slurry on the release paper) , to obtain a plurality of graphene oxide dielectric films in a semi-cured state with different graphene oxide mass percentages; in the present invention, the semi-cured state refers to a state between solid state and fluid state, which requires heating It can be fully cured, and the semi-cured state is convenient for subsequent ...

Embodiment 1

[0072] ① Disperse 5 g of γ-glycidyl etheroxypropyltrimethoxysilane (KH-560) into a mixture of water and ethanol (the volume ratio of water and ethanol is 3:1), and use glacial acetic acid to adjust the mixed solution pH to 3.5, stirred for 15 minutes until uniformly mixed to obtain a modification solution.

[0073] ② Add 100 g of graphene oxide to the modified solution obtained in ①, stir for 2 hours, then place the above modified solution in an oil bath at 80° C., heat and stir for 24 hours to obtain a functionalized graphene oxide solution.

[0074] ③ first use deionized water and ethanol to wash the functionalized graphene oxide solution prepared by ② for 3 times, then perform vacuum filtration on the functionalized graphene oxide solution after cleaning, and vacuum-dry the filter cake obtained by suction filtration at room temperature 24h, grind and obtain functionalized graphene oxide powder.

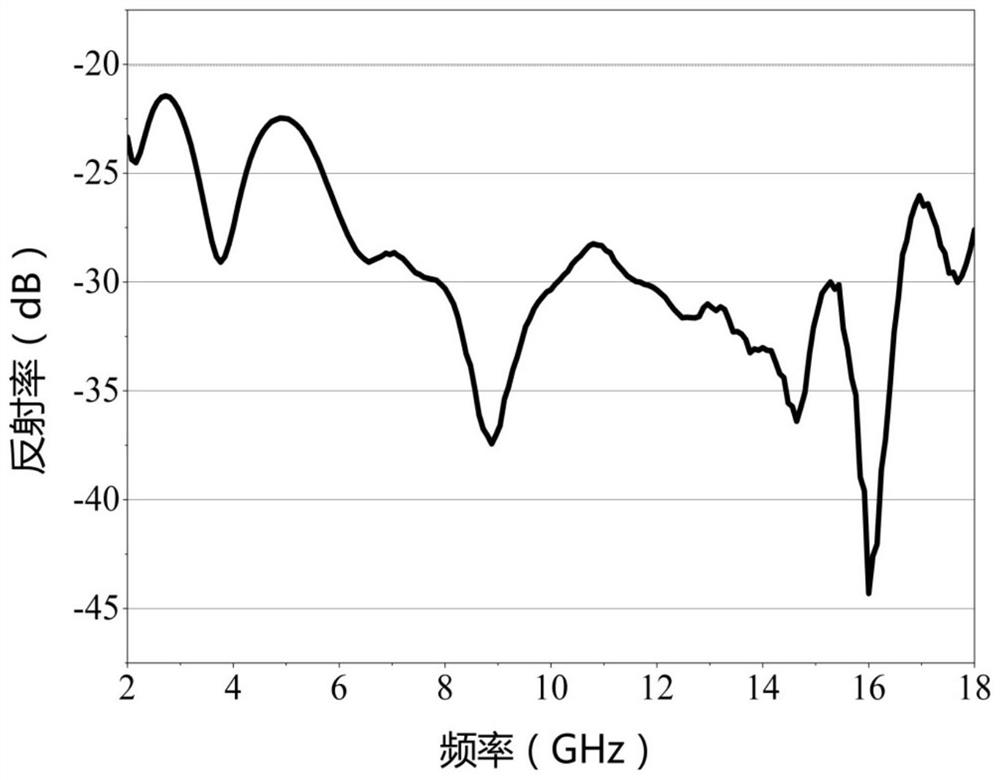

[0075] 4. 2.8g, 5.6g, 8.6g, 11.7g, 14.9g, 18.3g, 21.9g of 3. the functionaliz...

Embodiment 2

[0083] ① Disperse 3 g of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560) into a mixture of water and ethanol (the volume ratio of water and ethanol is 3:1), and adjust the mixed solution with glacial acetic acid pH to 3.5, stirred for 15 minutes until uniformly mixed to obtain a modification solution.

[0084] ② Add 100 g of graphene oxide to the modified solution obtained in ①, stir for 2 hours, then place the above modified solution in an oil bath at 80° C., heat and stir for 24 hours to obtain a functionalized graphene oxide solution.

[0085] ③ first use deionized water and ethanol to wash the functionalized graphene oxide solution prepared by ② for 3 times, then perform vacuum filtration on the functionalized graphene oxide solution after cleaning, and vacuum-dry the filter cake obtained by suction filtration at room temperature 24h, grind and obtain functionalized graphene oxide powder.

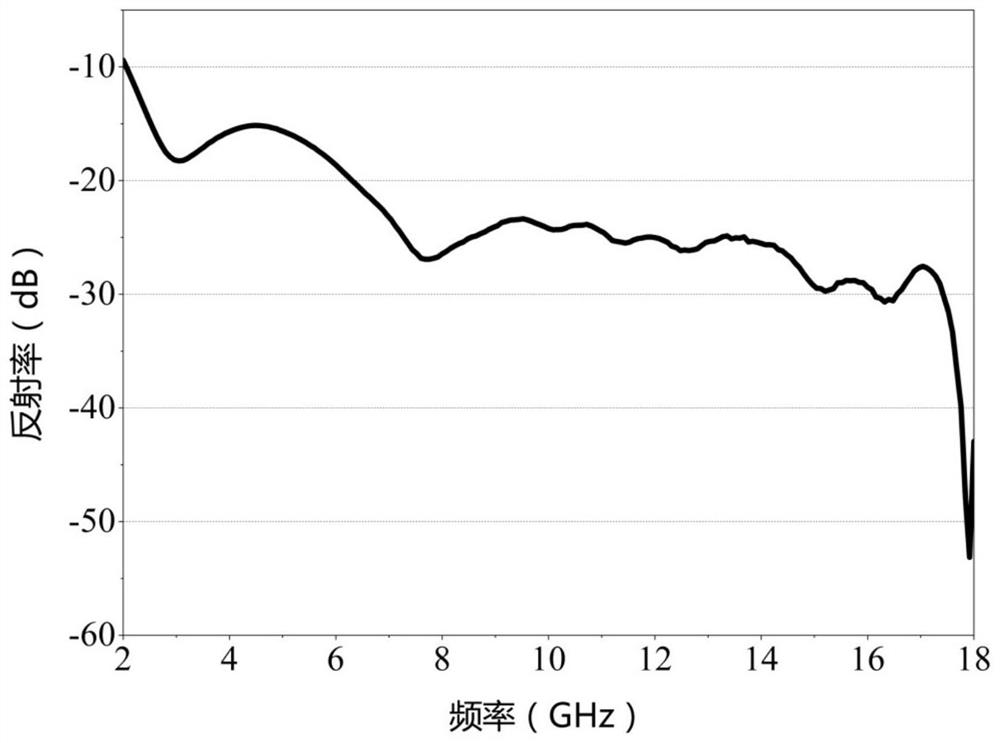

[0086]④ Disperse 3.06g, 9.57g, 16.67g, and 24.4g of the functionalized graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com