Ternary catalyst and preparation method and application thereof

A three-way catalyst and compound technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic effect of three-way catalysts and complicated preparation methods of three-way catalysts. The effect of improving the oxygen effluent effect, strengthening the loading effect, and improving the degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is the preparation of three-way catalyst.

[0040] Specific steps are as follows:

[0041] (1) Carrier selection: select γ-Al with a particle size of 2-3mm 2 o 3 Pellets as catalyst support, γ-Al 2 o 3 The pellets were purchased from Jiangsu Sanji Industrial Co., Ltd.

[0042] (2) Carrier activation: γ-Al 2 o 3 The pellets were washed with deionized water, and then dried in an oven at 65°C.

[0043] (3) Catalyst preparation: prepare three-way catalyst by impregnation roasting method, comprise the following steps:

[0044] 1) Precursor impregnating solution configuration: take 1% manganese nitrate aqueous solution, 1% ferric nitrate aqueous solution and 1.5% cerium nitrate aqueous solution, dissolve them in distilled water, stir well, and form a precursor after settling to 100mL body immersion solution;

[0045] 2) Impregnation: 20g γ-Al 2 o 3 The balls were immersed in the precursor impregnation solution, and were subjected to vibration impregna...

Embodiment 2

[0052] This embodiment uses the three-way catalyst of embodiment 1, the binary catalyst of comparative example 1, gamma-Al 2 o 3 The pellets were used to treat dairy cow breeding wastewater, and ozone was only used as a blank control.

[0053] Adjust the pH to 9, take four groups of 4L dairy cow breeding waste water of primary aerobic effluent, the water samples are taken from Guangzhou Huamei Milk Company (Qinglong Base), add 20g of three-way catalyst, two-way catalyst, γ- Al 2 o 3 Small balls, and then the four groups were respectively fed with ozone, and the dosage of ozone was 11.25mg·L -1 min -1 , The reaction time is 20min.

Embodiment 3

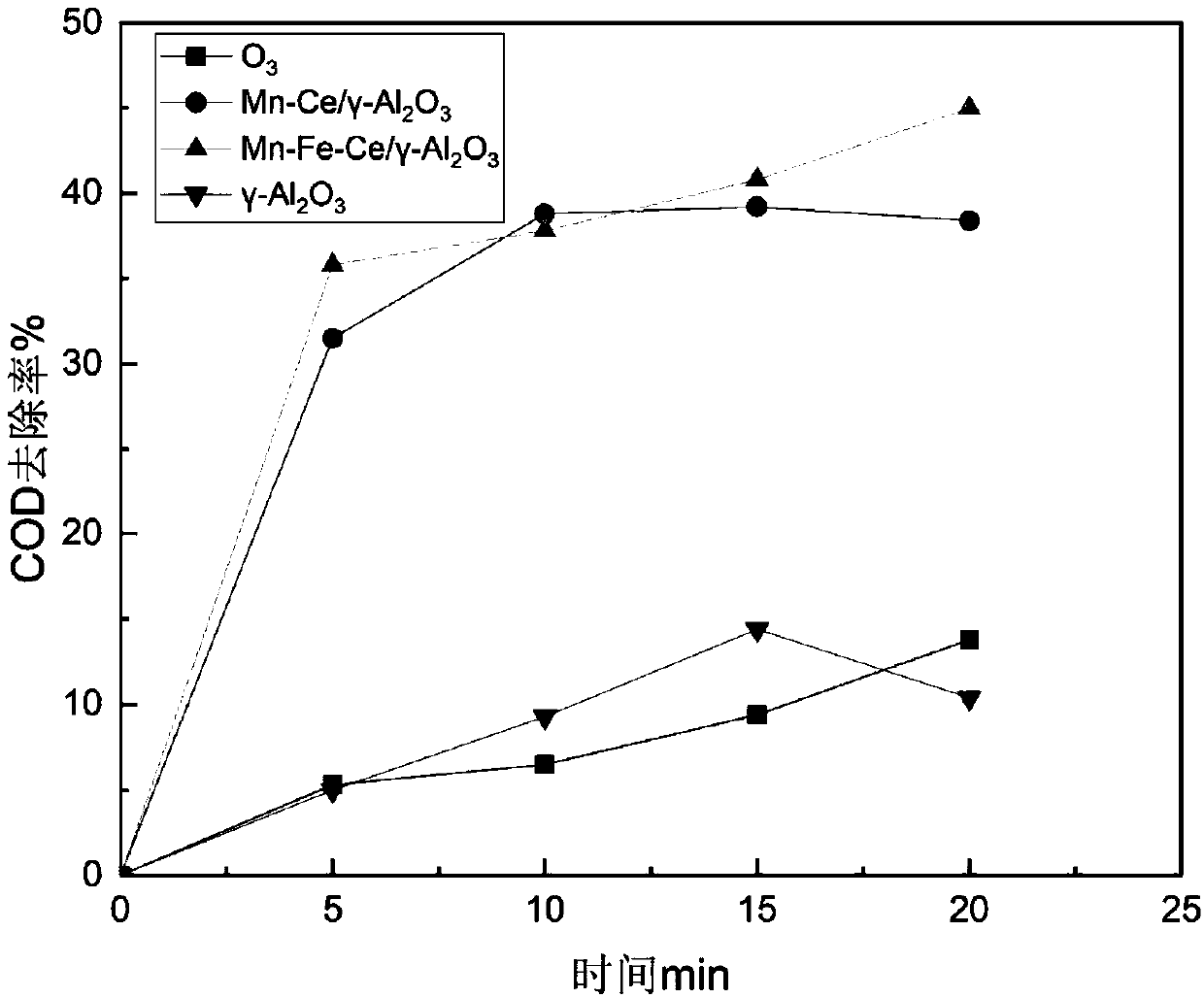

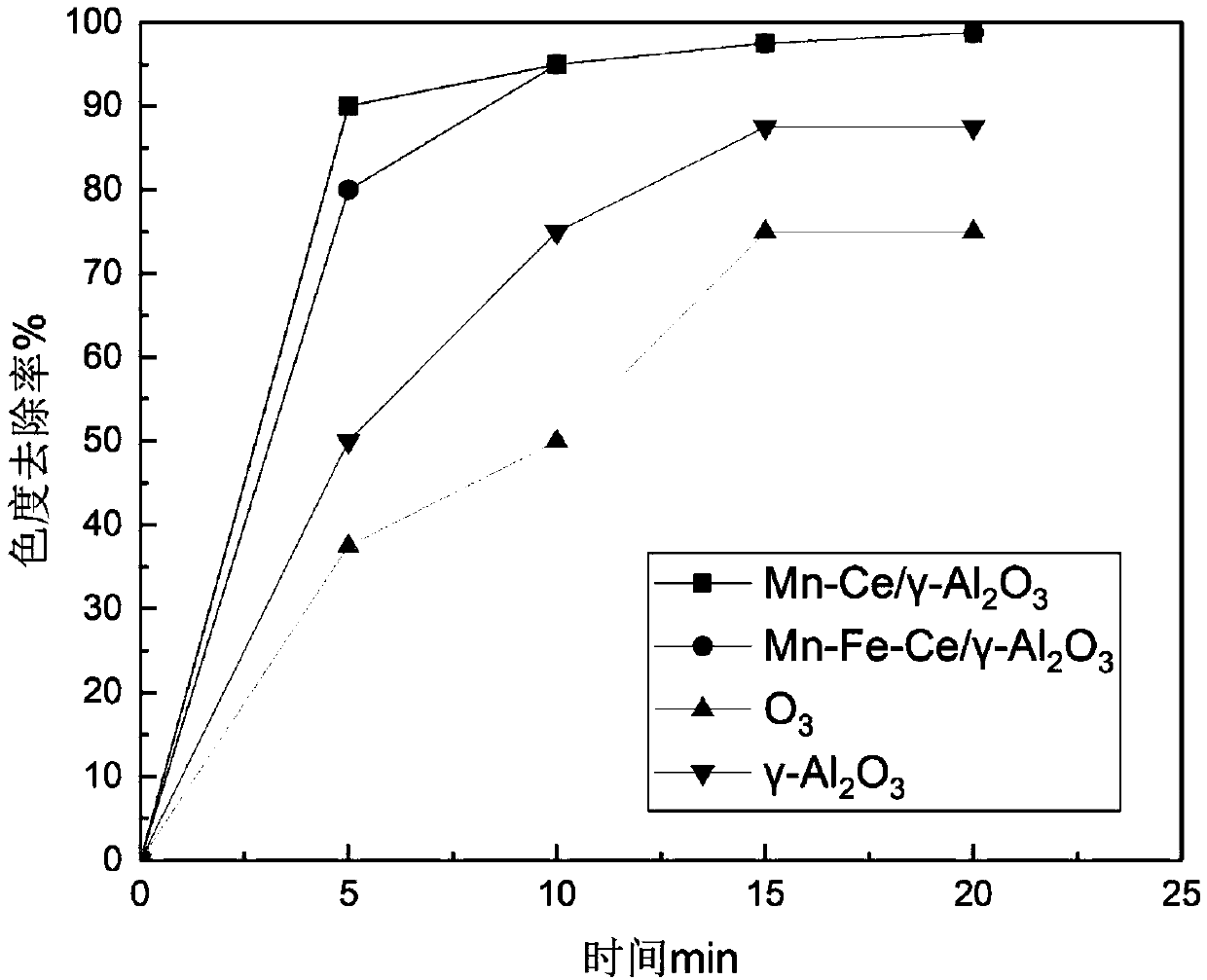

[0055] In this embodiment, samples were taken when the reaction time of Example 2 was 0min, 5min, 10min, 15min, and 20min, and the COD of the wastewater was measured by the ultraviolet spectrophotometer method, the COD removal rate of the wastewater was calculated, and the chroma of the wastewater was measured by the dilution factor method. Measurement results such as figure 1 , figure 2 shown.

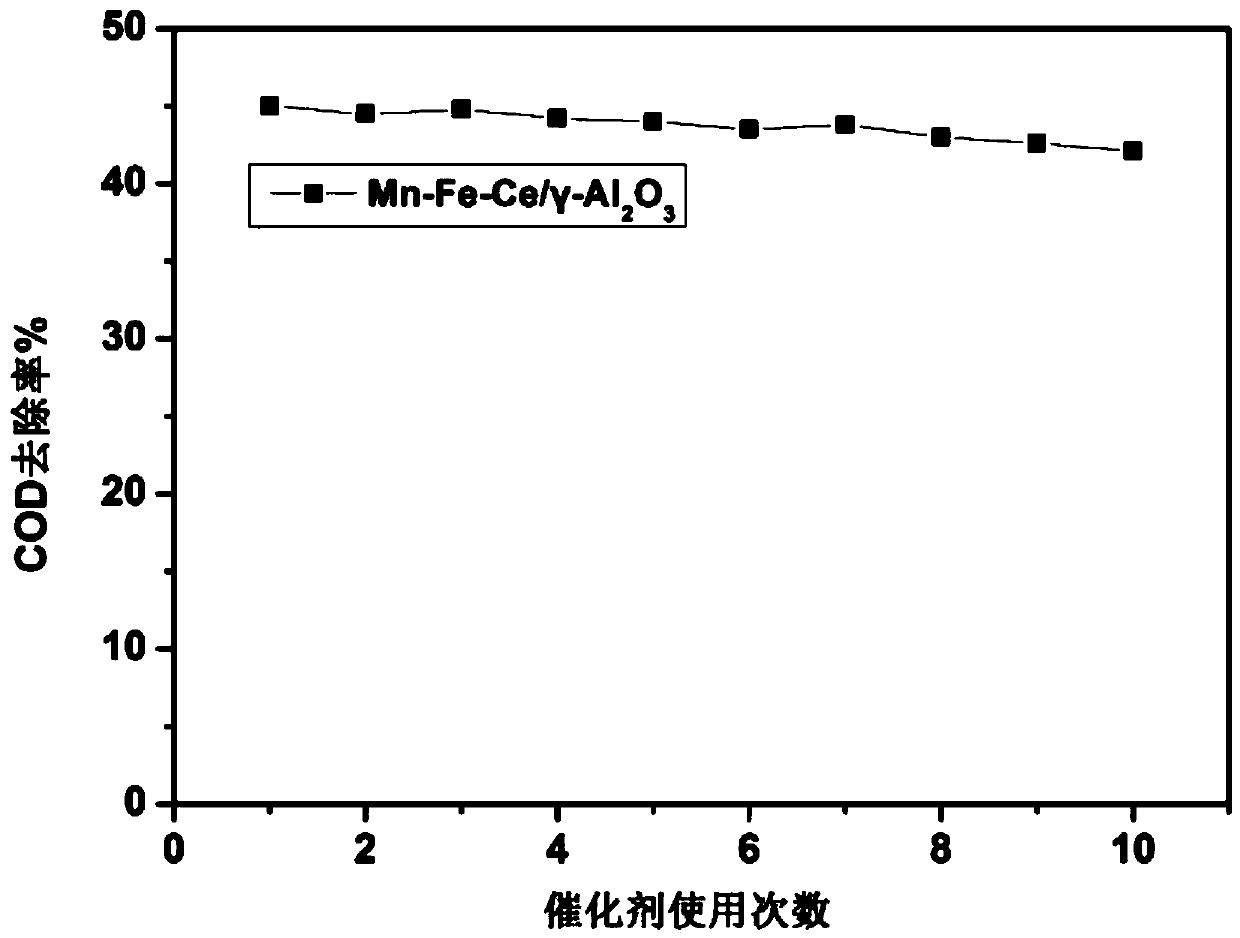

[0056] Depend on figure 1 It can be seen that when dealing with the actual dairy wastewater, because it is a complex system and contains more refractory biodegradable organic matter, the effect is significantly different from that of a single system. However, compared with the single ozone experiment and the single carrier catalytic ozonation experiment, the metal-loaded catalyst showed a significant COD removal rate, and the COD removal rate of the loaded three-way catalyst was better than that of the binary catalyst, with a removal rate of 45%. Such as image 3 As shown, the CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com