Positive paste, preparation method, anode piece and lithium ion battery

A technology of positive electrode slurry and positive electrode active material, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of chemical stability and insufficient cycle life, and achieve the effect of long cycle life and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

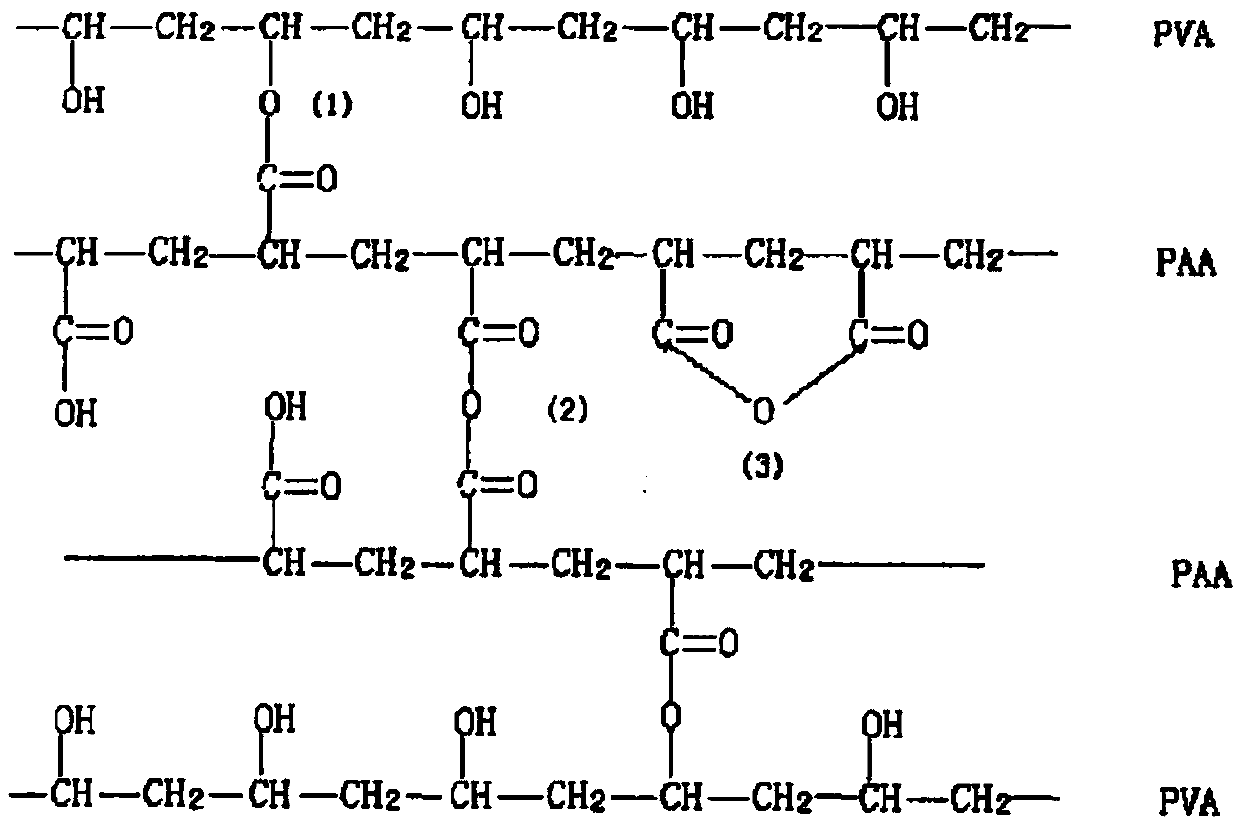

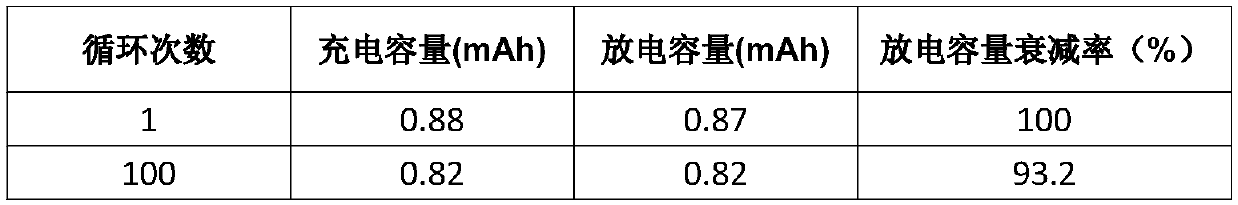

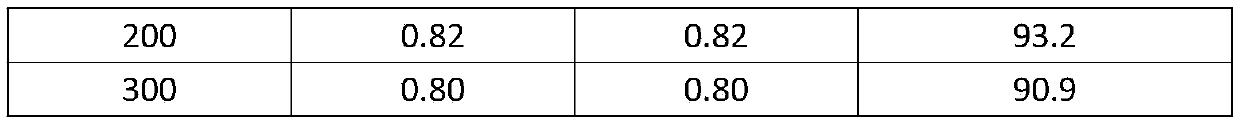

Embodiment 1

[0028] A positive electrode slurry comprising a positive electrode active material and a gel material doped with PEDOT. The gel material doped with PEDOT is a gel-like polymer compound obtained by polymerizing the solution system I under heating, and has a high gel The molecular compound is evenly distributed with PEDOT powder in an oxidized state; solution system I includes 75%-95% methyl acrylate, 1-15% PVA, 1-10% deionized water, 2%-10% Triethylene glycol dimethacrylate and 0.1%-5% hydrogen peroxide; the positive electrode active material includes a first positive electrode active material and a second positive electrode active material, the first positive electrode active material is a ternary material LiNi 0.5 Co 0.2 Mn 0.3 O 2 The second positive electrode active material is lithium cobalt oxide; the positive electrode active material is sintered from the first positive electrode active material and the second positive electrode active material, lithium ion and LiNi 0.5 Co ...

Embodiment 2

[0040] A positive electrode slurry comprising a positive electrode active material and a gel material doped with PEDOT. The gel material doped with PEDOT is a gel-like polymer compound obtained by polymerizing the solution system I under heating, and has a high gel The molecular compound is evenly distributed with PEDOT powder in an oxidized state; solution system I includes 75%-95% methyl acrylate, 1-15% PVA, 1-10% deionized water, 2%-10% Triethylene glycol dimethacrylate and 0.1%-5% hydrogen peroxide; the positive electrode active material includes a first positive electrode active material and a second positive electrode active material, the first positive electrode active material is a ternary material LiNi 0.8 Co 0.1 Mn 0.1 O 2 ; The second positive electrode active material is lithium cobalt oxide; lithium ion and LiNi 0.8 Co 0.1 Mn 0.1 O 2 The molecular ratio of is 10.5:1.

[0041] In this embodiment, PEDOT is a powder of 3,4-ethylenedioxythiophene monomer polymer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com