Ionic-electronic conductor composite film and preparation method thereof and lithium battery

A technology of electronic conductor and ion conductor, which is applied in the field of ion-electronic conductor composite film and its preparation method and lithium battery, can solve the problems of reducing the energy density of the battery, increasing the transmission distance of lithium ions, increasing the internal resistance of the battery, etc. Crystal, the preparation method is environmentally friendly, and the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the ion-electron conductor composite membrane provided in this embodiment, its steps are as follows figure 2 shown, including the following steps:

[0049] Step 210, adding the dispersant, binder, conductive additive, auxiliary agent and solvent into the pre-mixing tank according to the required ratio, and completely dissolving to obtain the first mixture;

[0050] Wherein, the solvent is a polar solvent, including deionized water, N-methylpyrrolidone (NMP), alcohol or dimethylformamide (DMF);

[0051] Binders include polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene, polytetrafluoroethylene, polymethylmethacrylate, polyacrylonitrile, styrene-butadiene latex, styrene-acrylic latex, polyvinyl alcohol, ethylene-vinyl acetate , sodium alginate, polyacrylamide, polymethyl methacrylate-butyl acrylate, ethylene-vinyl acetate copolymer, polyvinyl acetate, polyurethane, hydroxyethyl cellulose, methyl hydroxyethyl cellulose, carboxy...

Embodiment 1

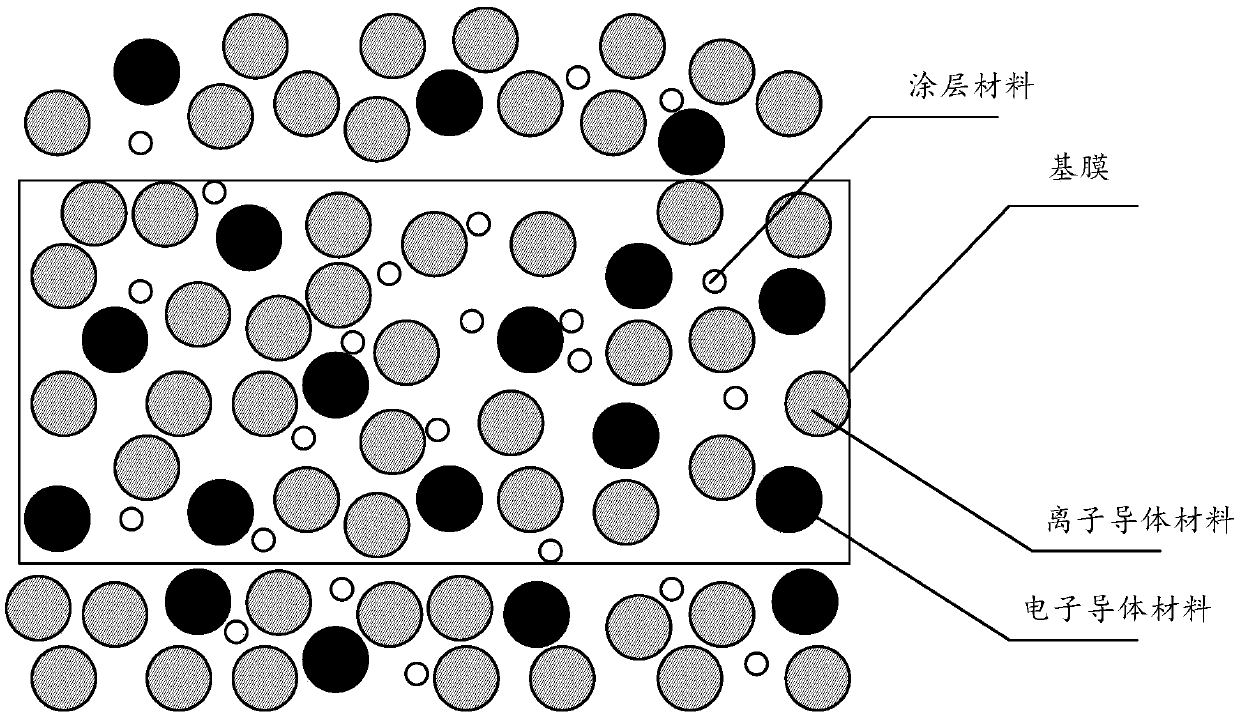

[0062] This embodiment provides an ion-electronic conductor composite membrane, including a base membrane and a coating material coated on the base membrane and penetrating into the base membrane. Wherein the base film is a polypropylene porous film with a thickness of 10um, adopts a single-sided coating method, the coating thickness is 4um, and the mass ratio of the coating slurry is: 20% composition and 80% deionized water; wherein, the combination The preparation of the product is according to the mass ratio: 88% ionic conductor material lithium titanium aluminum phosphate Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 Powder, 3% electronic conductor material carbon black SUPER-P, 5% coating material nano-alumina, 0.5% binder sodium carboxymethyl cellulose, 1% styrene-butadiene latex, 1% dispersant Sodium dodecylbenzene sulfonate, 0.5% octylphenol polyoxyethylene, 1% auxiliary polyvinyl alcohol.

[0063] The ion-electronic conductor composite membrane in this embodiment is prepared by...

Embodiment 2

[0070] This embodiment provides an ion-electronic conductor composite membrane, including a base membrane and a coating material coated on the base membrane and penetrating into the base membrane. Wherein the base film is a polypropylene porous film with a thickness of 10um, adopts a single-sided coating method, the coating thickness is 4um, and the mass ratio of the coating slurry is: 30% composition and 70% deionized water; wherein, the composition The preparation is according to the mass ratio: 5% ionic conductor material lithium titanium aluminum phosphate Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3Powder, 5% electronic conductor material carbon black SUPER-P, 86% coating material nano-alumina, 1% binder sodium carboxymethyl cellulose, 1% styrene-butadiene latex, 1% dispersant Sodium polyacrylate and 1% polyethylene glycol 1%.

[0071] The method for preparing the ion-electron conductor composite membrane is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com