Vacuum melting process of aluminum-free low-oxygen steel

A technology for vacuum melting and low-oxygen steel, applied in the field of iron and steel metallurgy, can solve problems such as aluminum inclusions, and achieve the effects of reducing the temperature of molten steel, reducing oxygen transfer, and optimizing the alloying sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

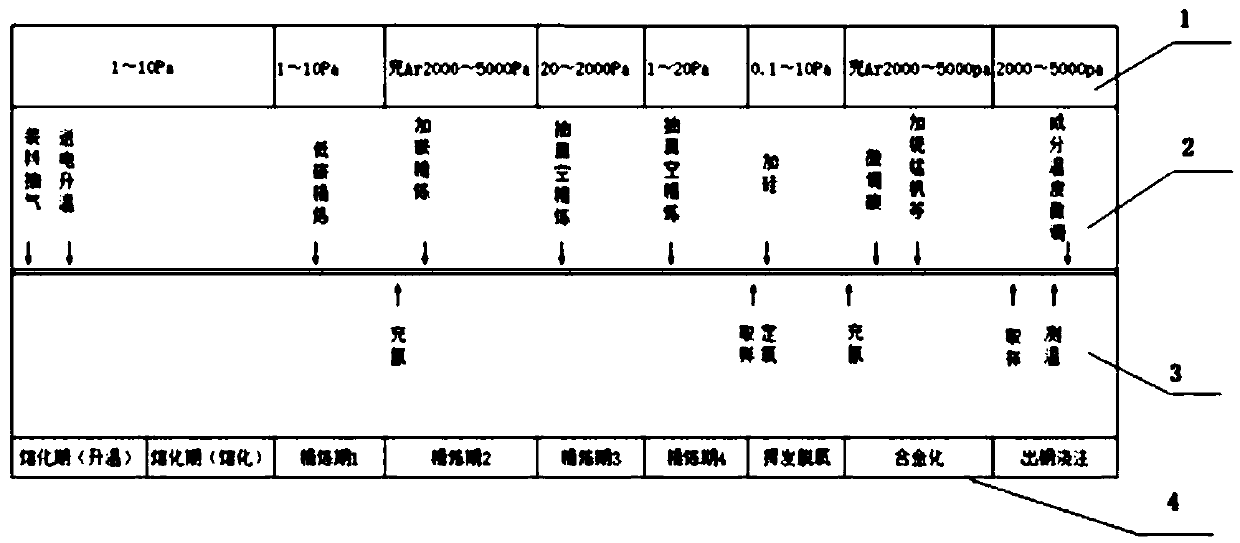

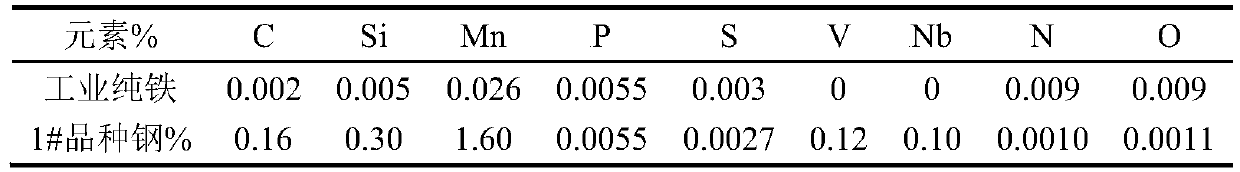

[0038] A vacuum smelting process for aluminum-free low-oxygen steel, using industrial pure iron (see Table 1 for composition information) to smelt 1# variety steel, the furnace lining is made of MgO crucible, and smelted in a 50kg vacuum induction furnace. The process flow chart is shown in figure 1 , including the following steps:

[0039] 1) Pretreatment of raw materials; the industrial pure iron used is treated with surface derusting, and the alloy raw materials used in the smelting process are used after being dried in a baking furnace; the loading capacity is 47kg, and the furnace capacity utilization rate is 94%;

[0040] 2) Melting period; carbon is added to the furnace charge (industrial pure iron) for deoxidation during the melting period, and the amount of carbon to be mixed is 10g according to the initial oxygen content in the raw material; after charging, the gas is pumped to 1000pa and the temperature is raised by 30KW power supply. After 10 minutes, feed 60KW. Af...

Embodiment 2

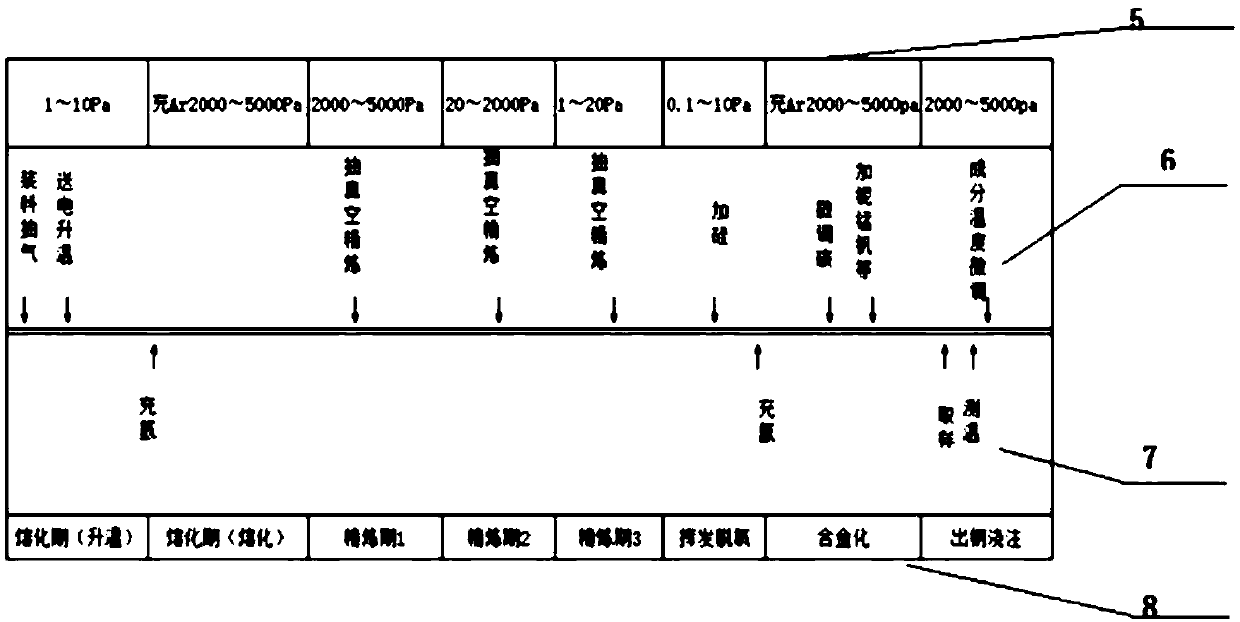

[0050] A vacuum smelting process for aluminum-free low-oxygen steel, using carbon steel (see Table 3 for composition information, with carbon raw material) to smelt 2# variety steel, the furnace lining is made of MgO crucible, and smelted in a 50kg vacuum induction furnace. The process flow chart is shown in figure 2 , the important steps and parameter conditions involved include:

[0051] 1) Melting period; the raw material is carbon steel, which contains enough carbon in the melting stage and participates in deoxidation. During the melting process, when the surface of the molten steel fluctuates greatly, fill in 5000pa of argon to adjust the atmosphere in the furnace, and adjust the power to 30-40KW. Control the degree of reaction during the melting period; after the charge is completely melted, the surface of the solution continues to react until the surface of the solution is calm, indicating that under the pressure of 5000pa argon atmosphere, the molten steel has entered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com