Tar purification treatment method and system

A technology for purification treatment and tar, which is applied in the direction of gasification process, petroleum industry, and manufacture of combustible gas, etc., to achieve the effect of avoiding processing problems, reducing tar content, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

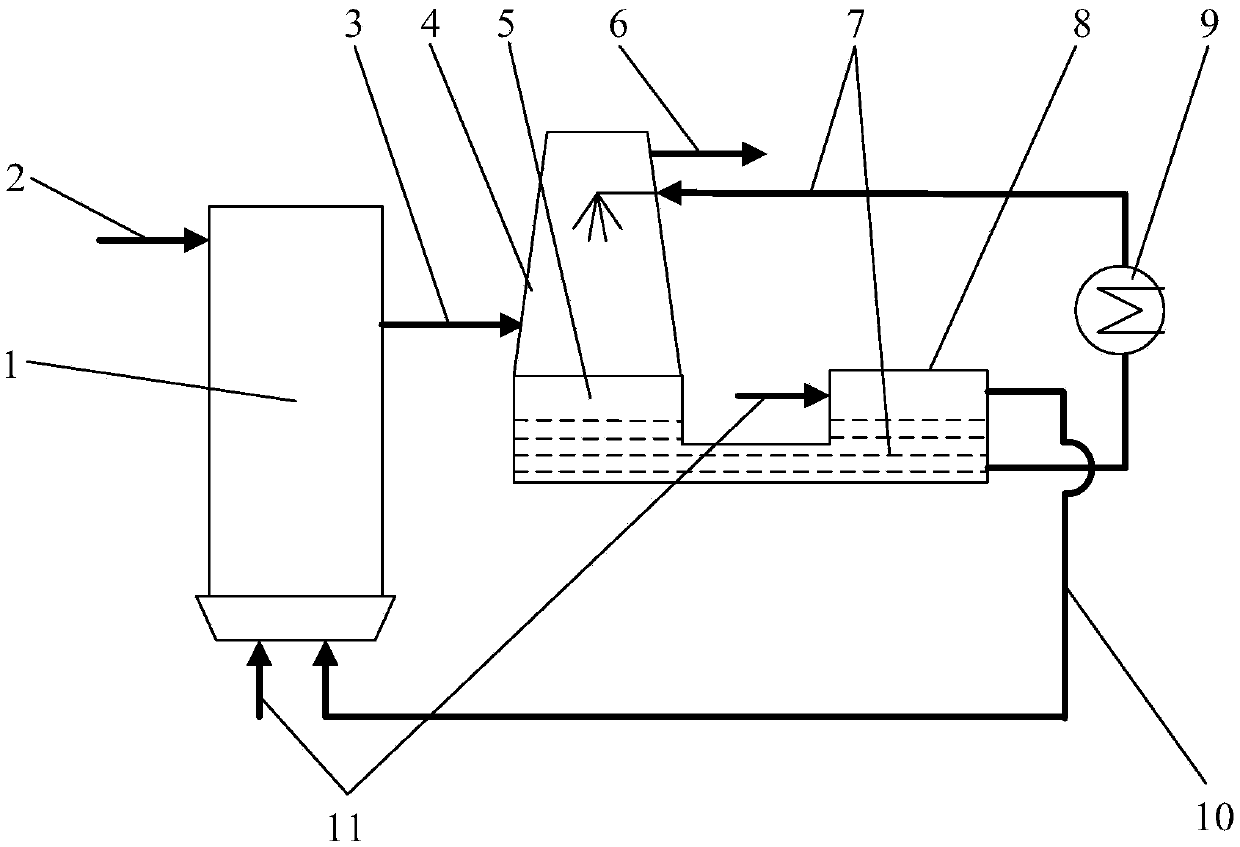

[0028] A method for tar purification treatment, comprising the following steps:

[0029] (1) The crude gas 3 from the outlet of the gasifier 1 enters the cooling scrubber 4, cools and removes tar, and obtains a clean gas 6;

[0030] (2) The tar waste liquid flows into the first circulating water tank 5, and the first circulating water tank 5 communicates with the second circulating water tank 8, and the tar waste liquid 7 enters the second circulating water tank 8 from the first circulating water tank 5, and is cooled by the circulating water cooler 9 After that, re-enter the cooling scrubber 4 to cool, wash and purify the crude gas 3, forming a cycle;

[0031] (3) The gasification agent 11 passes through the tar waste liquid 7 in the second circulating water tank 8 , and the gasification agent 10 carrying the volatilized tar waste liquid enters the gasifier 1 and reacts with the biomass 2 to generate the crude gas 3 .

[0032] (4) The furnace body of gasifier 1 is lengthened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com