Treating liquid recycling device for tail gas treatment

A recovery device and tail gas treatment technology, applied in the direction of using liquid separation agent, feeding/discharging device of sedimentation tank, sedimentation tank, etc., can solve the problem that the treatment liquid cannot be recycled and reused, the treatment liquid cannot be separated, and the treatment liquid is lost. Fast and other problems, to achieve good flocculation effect, reduce the difficulty of treatment, and achieve the effect of recycling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

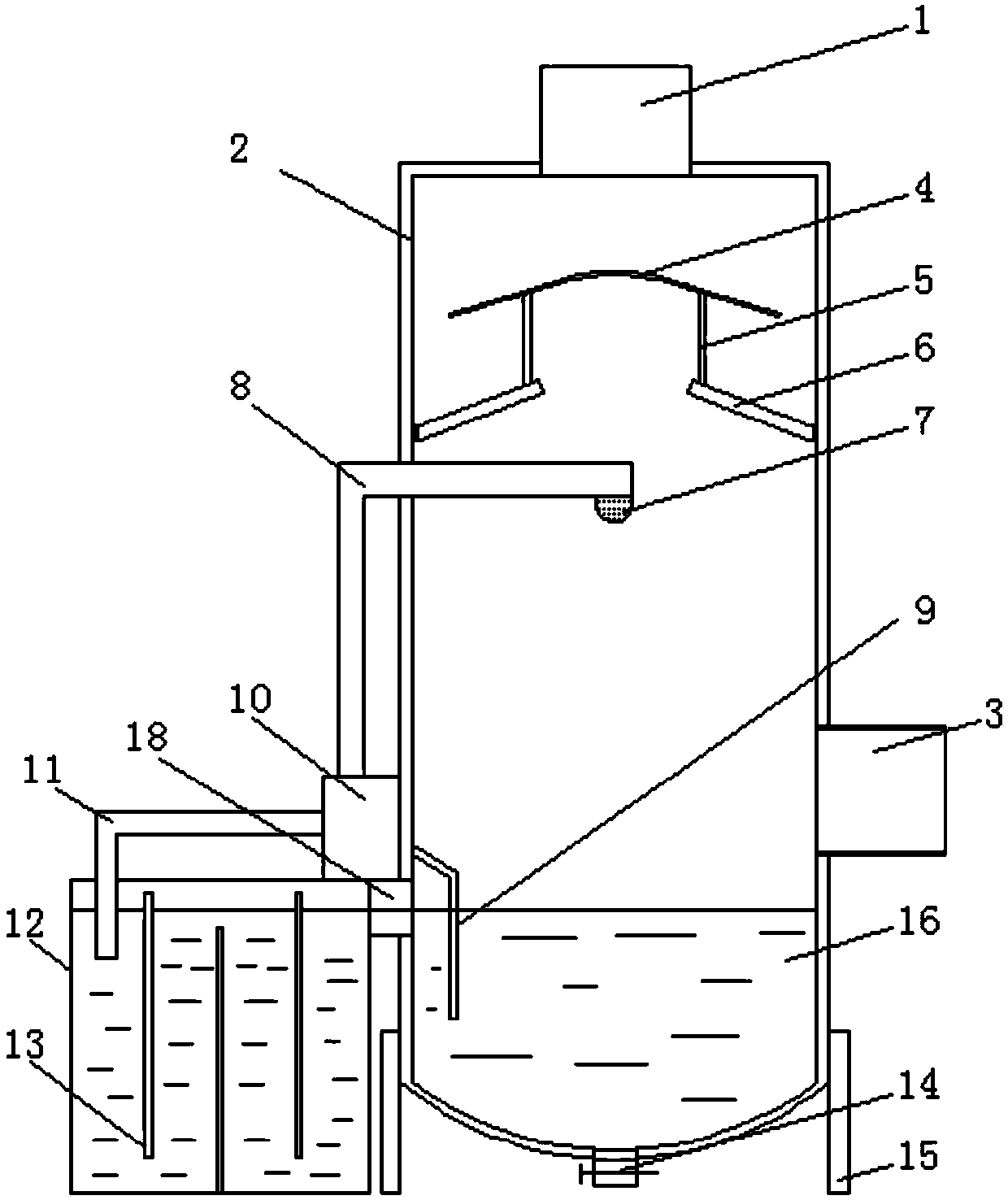

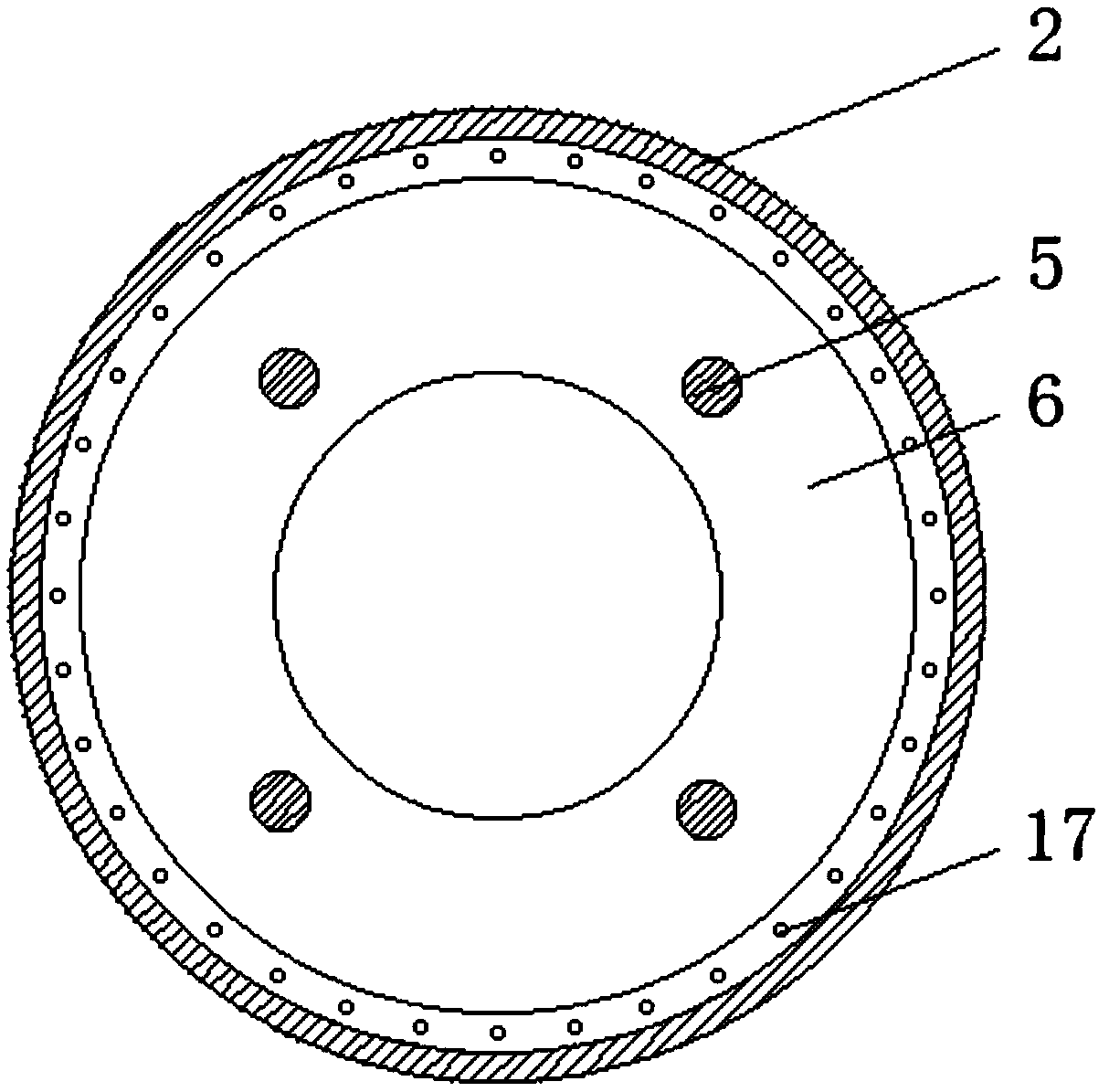

[0030] Embodiment 1, a treatment liquid recovery device for tail gas treatment, comprising a treatment tank 2, an air intake pipe 3 and an exhaust pipe 1, the upper end of the treatment tank 2 is provided with an exhaust pipe 1, and the bottom of the treatment tank 2 is provided with a number of evenly distributed fixed frame 15, and the bottom side of the treatment tank 2 is provided with an air intake pipe 3, the middle part of the treatment tank 2 is provided with a nozzle 7, and the treatment liquid 16 is arranged in the treatment tank 2 at the bottom of the air intake pipe 3, and the treatment One side of the tank 2 is provided with a separation box 12, and the inlet of the upper end of the side of the separation box 12 is provided with a connecting pipe 18, and the inlet of the upper end of the separation box 12 is communicated with the treatment tank 2 side through the connecting pipe 18, and the separation box 12 The upper end is provided with a water pump 10, and one s...

Embodiment 2

[0034] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0035] Preferably, the separation box 12 located between the water inlet and the water outlet is provided with a number of distribution plates 13 with the same size and uniform distribution up and down, and the distribution plates 13 at the bottom are fixed to the bottom of the separation box 12. Connection, a communication groove (not shown in the figure) is provided between the bottom of the splitter plate 13 at the upper end and the bottom of the separation box 12. The diverter plate in the separation box greatly increases the residence time of the treatment liquid in the treatment box, thereby improving the precipitation effect of impurities in the treatment liquid, ensuring the purity of the treatment liquid, and ensuring the subsequent treatment efficiency of the treatment liquid.

[0036] Preferably, a sewage discharge pipe 14 is provided at the bottom of the treatment tank...

Embodiment 3

[0038] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0039] Preferably, the treatment tank 2 located on one side of the communication pipe 18 is provided with a baffle 9 inclined downward, the upper end of the baffle 9 is located at the upper end of the communication pipe 18, and the bottom of the baffle 9 is located at the upper end of the communication pipe 18. below the bottom. The addition of the deflector allows the sprayed treatment liquid to settle to a certain height before entering the separation box through the connecting pipe, which improves the precipitation efficiency of the treatment liquid in the treatment tank and reduces the treatment pressure in the separation box. Ensure the overall precipitation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com