Red mud-based composite flocculating agent for domestic sewage treatment and preparation method thereof

A composite flocculant and domestic sewage technology, which is applied in water/sludge/sewage treatment, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the limitations of application range, low scum production, mutagenesis, etc. problem, to achieve good flocculation effect, reduce processing difficulty and improve activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

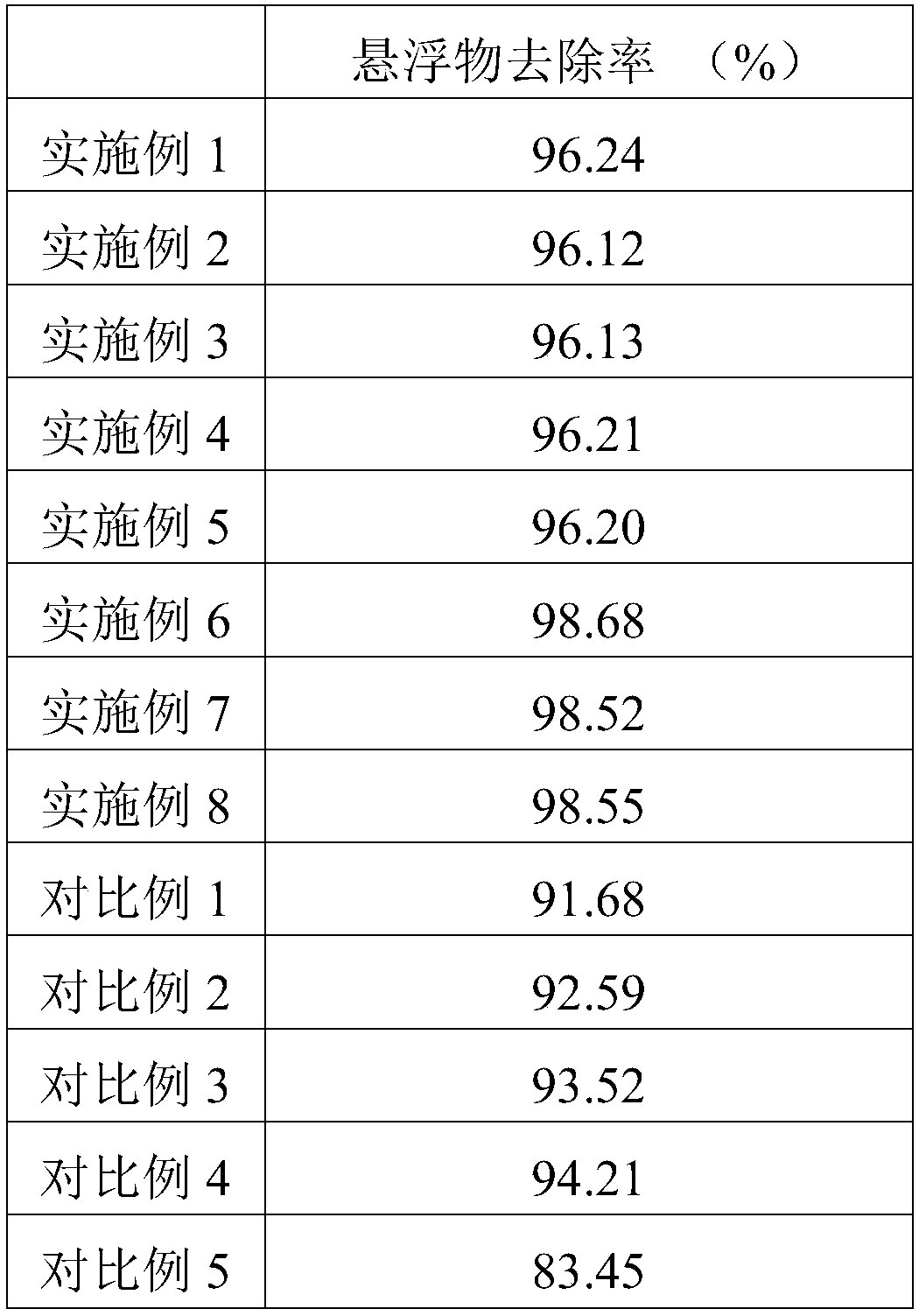

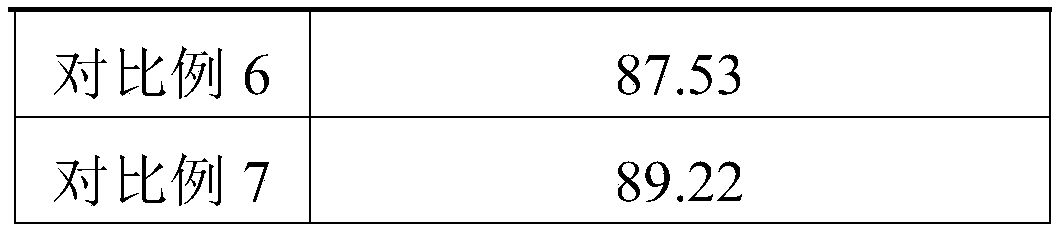

Examples

preparation example Construction

[0024] The invention provides a preparation method of a red mud-based composite flocculant for domestic sewage treatment, comprising the following steps:

[0025] (1) Add waste sulfuric acid to the red mud, stir and mix, let stand for 30-60 minutes, filter, dry the filtrate, grind and refine to obtain red mud powder with a particle size of 90-100 mesh, and set aside;

[0026] (2) Adding coal powder to the red mud powder, mixing evenly and roasting at high temperature to obtain activated red mud powder;

[0027] (3) Add magnesium aluminum silicate to the activated red mud powder, spray the ethanol solution of ethylene glycol diglycidyl ether into the process of stirring and mixing, after stirring and mixing evenly, put it into a vacuum drying oven and dry to constant weight, That is, the composite flocculant is obtained.

[0028] The red mud mentioned in the present invention is the polluting waste slag discharged during the extraction of alumina in the aluminum industry. Gene...

Embodiment 1

[0044] A preparation method of composite flocculant, comprising the following steps:

[0045] (1) Add waste sulfuric acid to the red mud, stir and mix, filter after standing for 40 minutes, dry the filtrate, grind and refine to obtain red mud powder with a particle size of 90 mesh, and set aside;

[0046] Wherein, the addition amount of the waste sulfuric acid is based on the pH value of the supernatant after stirring, mixing and standing still; 6.0~7.0;

[0047] (2) Add coal powder to the red mud powder, the weight ratio of the red mud powder to coal powder is 1:0.4;

[0048] After mixing evenly, perform high-temperature roasting at a temperature of 500°C and a pressure of -100 MPa in the roaster, and naturally cool after roasting to obtain activated red mud powder;

[0049] (3) Add magnesium aluminum silicate to the activated red mud powder, spray the ethanol solution of ethylene glycol diglycidyl ether into the process of stirring and mixing, after stirring and mixing even...

Embodiment 2

[0052] As in the preparation method of the composite flocculant provided in Example 1, the difference is that in step (3), the weight ratio of the activated red mud powder, magnesium aluminum silicate, ethylene glycol diglycidyl ether, and ethanol is 1 :0.2:0.05:0.3;

[0053] With the rest unchanged, the composite flocculant was prepared according to the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com