Preparation method of reversed-phase demulsification water purifying agent for oil-containing sewage treatment of thickened oil

A technology for milk water purifier and oily water purifier, which is applied in the field of inverse demulsification and water purifier, and can solve problems such as poor high temperature resistance, easy adhesion of dirty oil into agglomerates, and impact on equipment separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

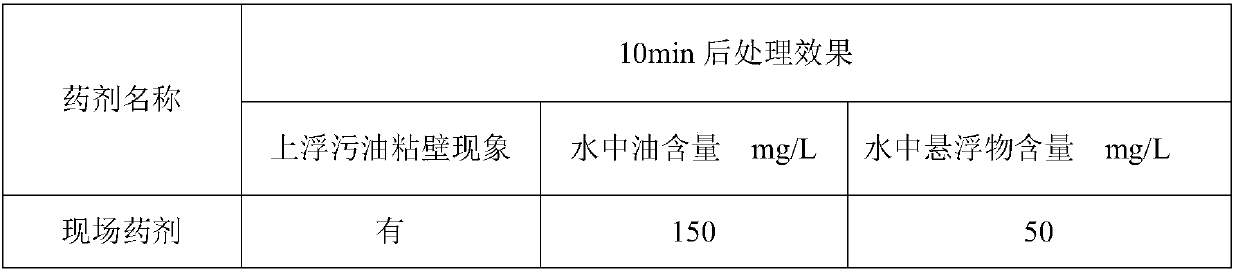

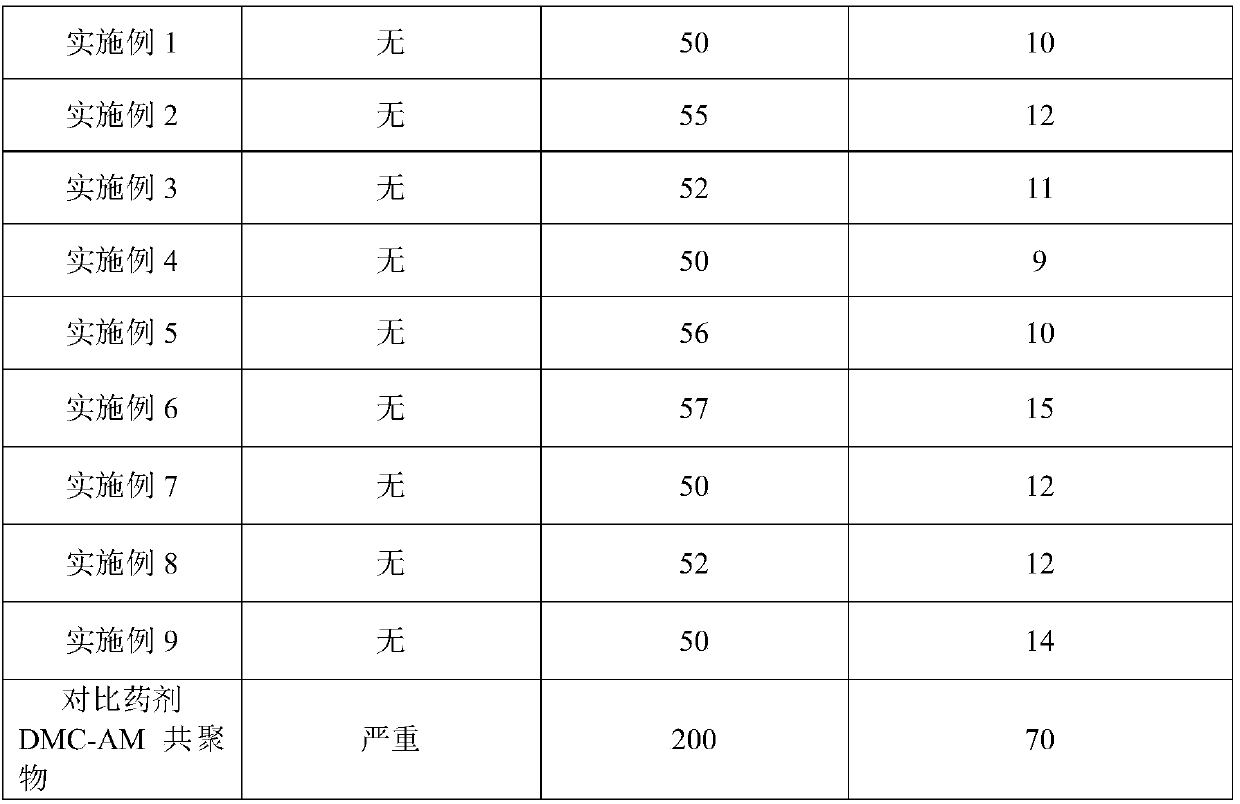

Examples

Embodiment 1

[0018] 1) Preparation of prepolymer

[0019] Add N,N dimethylethanolamine (4.60g, 0.05168mol) and 0.302g catalyst KOH in a closed reactor with a thermometer and a stirrer, vacuumize, and start stirring, the reaction mixture is heated to 140 ° C, and then Propylene oxide (150.00g, 2.586mol) was added slowly, and the addition was completed after 5h. Then, the temperature of the reaction mixture was raised to 160°C, and then ethylene oxide (147.86g, 3.360mol) was added slowly, and the addition was completed after 4h, and the reaction was kept for 3h. , stop the stirring reaction to obtain the prepolymer;

[0020] 2) Preparation of reverse phase demulsification water purifier

[0021] Add the prepolymer (200.00g, 0.03419mol) and ethanol 200.00g prepared in step 1) to a closed reactor with a thermometer, a stirrer and start stirring. The reaction mixture is warmed up to 60°C, and then methyl chloride (1.71g ,0.03419mol) was added slowly, and after 1h, the reaction was kept for 3h...

Embodiment 2

[0023] 1) Preparation of prepolymer

[0024] Add N,N dimethylethanolamine (4.60g, 0.05168mol) and 0.302g catalyst KOH in a closed reactor with a thermometer and a stirrer, vacuumize, and start stirring, the reaction mixture is heated to 140 ° C, and then Propylene oxide (155.90g, 2.688mol) was added slowly, and the addition was completed after 5h. Then, the temperature of the reaction mixture was raised to 160°C, and then ethylene oxide (154.70g, 3.516mol) was slowly added, and the addition was completed after 4h, and the reaction was kept for 3h , stop the stirring reaction to obtain the prepolymer;

[0025] 2) Preparation of reverse phase demulsification water purifier

[0026] Add the prepolymer (200.00g, 0.03329mol) and ethanol 200.00g prepared in step 1) to a closed reactor with a thermometer, a stirrer and start stirring. The reaction mixture is warmed up to 60°C, and then methyl chloride (1.66g ,0.03329mol) was added slowly, and after 1 hour of addition, the heat pres...

Embodiment 3

[0028] 1) Preparation of prepolymer

[0029] Add N,N dimethylethanolamine (4.60g, 0.05168mol) and 0.302g catalyst KOH in a closed reactor with a thermometer and a stirrer, vacuumize, and start stirring, the reaction mixture is heated to 140 ° C, and then Propylene oxide (164.84g, 2.842mol) was added slowly, and the addition was completed in 5h. Then, the temperature of the reaction mixture was raised to 160°C, and then ethylene oxide (166.01g, 3.773mol) was added slowly, and the addition was completed in 4h, and the reaction was kept for 3h. , stop the stirring reaction to obtain the prepolymer;

[0030] 2) Preparation of reverse phase demulsification water purifier

[0031] Add the prepolymer (200.00g, 0.03081mol) and ethanol 200.00g prepared in step 1) to a closed reactor with a thermometer, a stirrer and start stirring. The reaction mixture is warmed up to 60°C, and then methyl chloride (1.54g ,0.03081mol) was added slowly, and after 1 hour of addition, the heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com