Anti-static antibacterial PBT/ASA material and preparing method and application thereof

An antistatic and antistatic agent technology, which is applied in antibacterial PBT/ASA materials, antistatic, and preparation fields, can solve the problems of low rigidity, limited ability to withstand force, lack of antistatic, antibacterial, etc., to achieve Improved weather resistance, reduced surface resistance, and long-term antistatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0026] The present invention will be described in detail below in conjunction with examples.

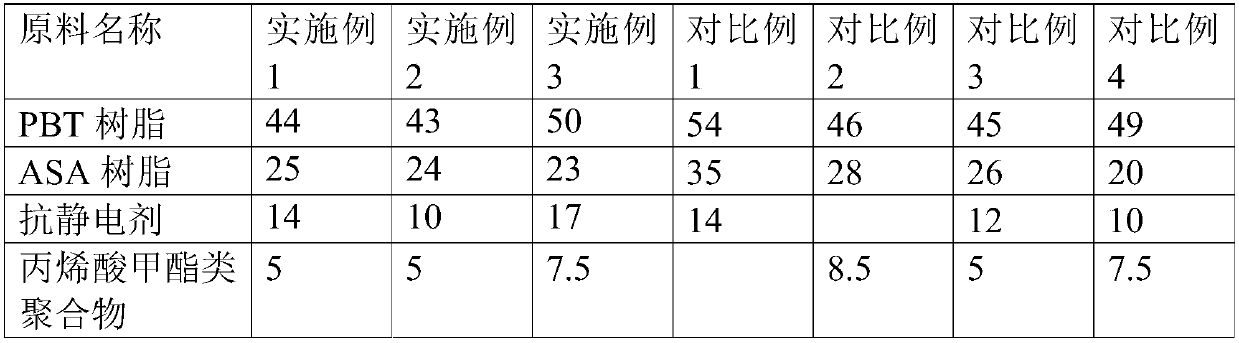

[0027] The raw materials selected in the following examples and comparative examples are specifically:

[0028] Among them, the PBT resin is PBT with high fluidity, and the melt flow rate is 25-40g / 10min (250°C, 10kg).

[0029] ASA resin is a copolymer of acrylonitrile-styrene-acrylic rubber, preferably a high-melt index type, with a melt flow rate of 15-25g / 10min (220°C, 10kg).

[0030] The antistatic agent is a permanent antistatic agent, including metal salt and polyoxyethylene; the pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com