A kind of preparation method of high-purity magnesium saponite

A magnesium saponite, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems affecting performance, difficult to remove impurities, impurity of saponite crystals, etc., to improve purity and reduce impurities Formation, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

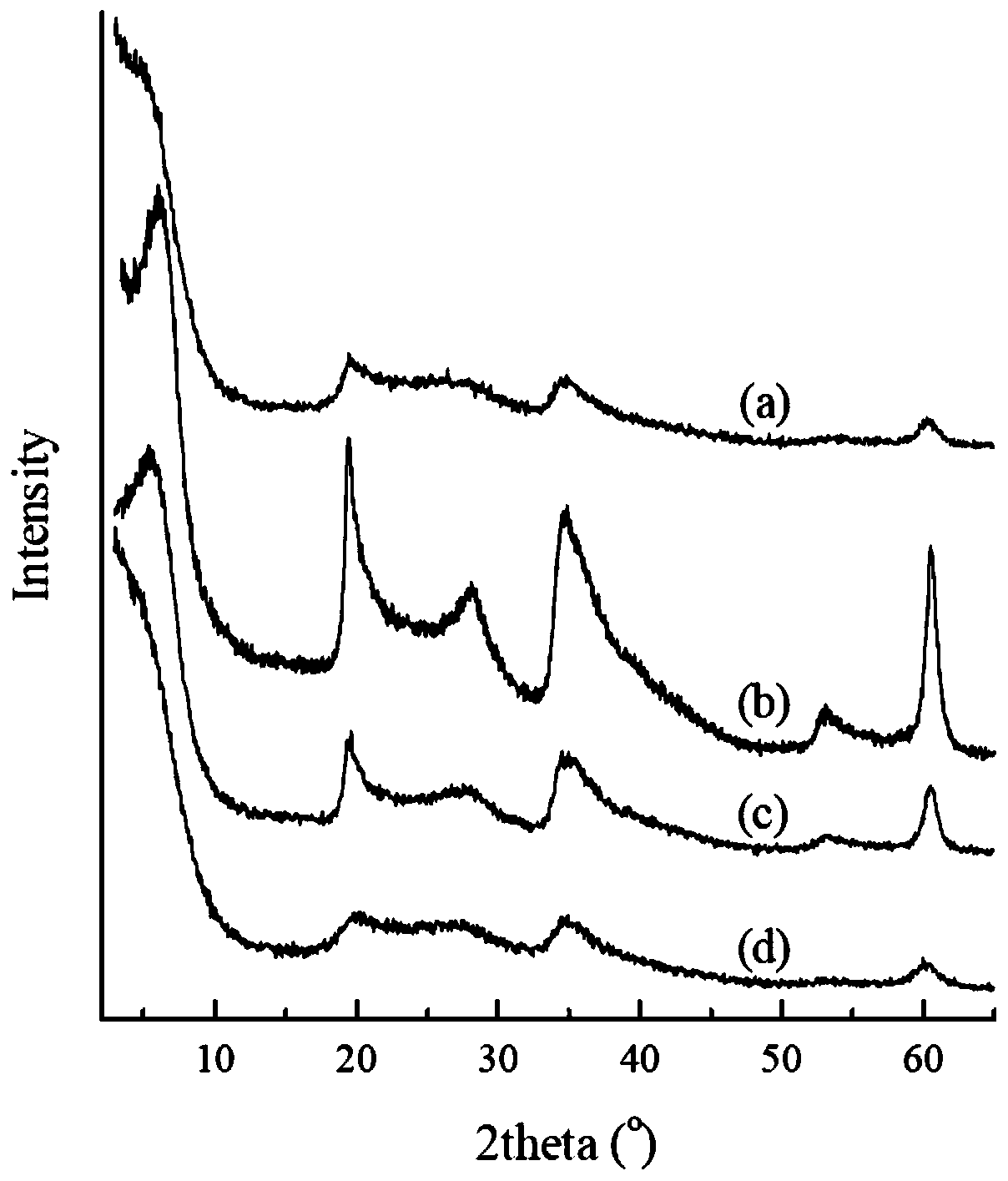

Image

Examples

Embodiment 1

[0031] A kind of preparation method of high-purity stevensite of the present embodiment, comprises the steps:

[0032] 1) According to silicon in water glass: deionized water: the mol ratio of sodium hydroxide is 1.0: 63.0: 1.0, water glass 288.9g, deionized water 1474g, sodium hydroxide 52.8g are mixed, be mixed with the aqueous solution containing silicon .

[0033] 2) According to the molar ratio of magnesium in the magnesium salt: deionized water being 1:16.7, 256 g of magnesium nitrate hexahydrate and 300 g of deionized water were prepared into an aqueous solution containing magnesium.

[0034] 3) According to the molar ratio of aluminum in aluminum salt: deionized water: sodium hydroxide: sodium bicarbonate: potassium in potassium salt is 1.0: 1481.5: 53.9: 59.5: 20.3, aluminum chloride hexahydrate 7.25g, deionized Mix 800 g of ionized water, 64.7 g of sodium hydroxide, 150 g of sodium bicarbonate, and 45.3 g of potassium chloride to prepare an aluminum-containing aqueo...

Embodiment 2

[0038] A kind of preparation method of high-purity stevensite of the present embodiment, comprises the steps:

[0039] 1) According to silicon in water glass: deionized water: the molar ratio of sodium hydroxide is 1.0: 71.1: 0.90, water glass 277.8g, deionized water 1600g, sodium hydroxide 46.2g are mixed, be mixed with the aqueous solution containing silicon .

[0040] 2) According to the molar ratio of magnesium in the magnesium salt: deionized water is 1:22.2, 203g of magnesium chloride hexahydrate and 400g of deionized water are prepared into an aqueous solution containing magnesium.

[0041] 3) According to the molar ratio of aluminum in aluminum salt: deionized water: sodium hydroxide: sodium bicarbonate: potassium in potassium salt is 1.0: 388.9: 17.5: 19: 9.4, aluminum chloride hexahydrate 24.15g, deionized Mix 700g of ionized water, 70.0g of sodium hydroxide, 160g of sodium bicarbonate, and 70g of potassium chloride to prepare an aluminum-containing aqueous solution...

Embodiment 3

[0045] A kind of preparation method of high-purity stevensite of the present embodiment, comprises the steps:

[0046] 1) According to silicon in water glass: deionized water: the molar ratio of sodium hydroxide is 1.0: 76.9: 0.9, water glass 255.6g, deionized water 1591g, sodium hydroxide 39.6g are mixed, be mixed with the aqueous solution containing silicon .

[0047] 2) According to the magnesium in the magnesium salt: the molar ratio of deionized water is 1: 27.8, 203g of magnesium chloride hexahydrate and 500g of deionized water are prepared into an aqueous solution containing magnesium.

[0048] 3) According to the molar ratio of aluminum in the aluminum salt: deionized water: sodium hydroxide: sodium bicarbonate: potassium in the potassium salt is 1.0: 166.7: 8.6: 10.1: 3.5, 75.0 g of aluminum nitrate nonahydrate, deionized Mix 600 g of water, 68.6 g of sodium hydroxide, 170 g of sodium bicarbonate, and 70.7 g of potassium nitrate to prepare an aluminum-containing aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com