Cover plate structure and manufacturing method thereof, and capacitive sensor

A cover plate and electrical device technology, applied in the field of micro-electromechanical device design and manufacturing, can solve the problems of lack of wide applicability, large parasitic capacitance, high manufacturing cost, etc., achieve no need for high temperature, reduce parasitic capacitance, and good airtightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0055] In a first embodiment of the present disclosure, a cover structure in which an insulating material forms a sealed cover is provided.

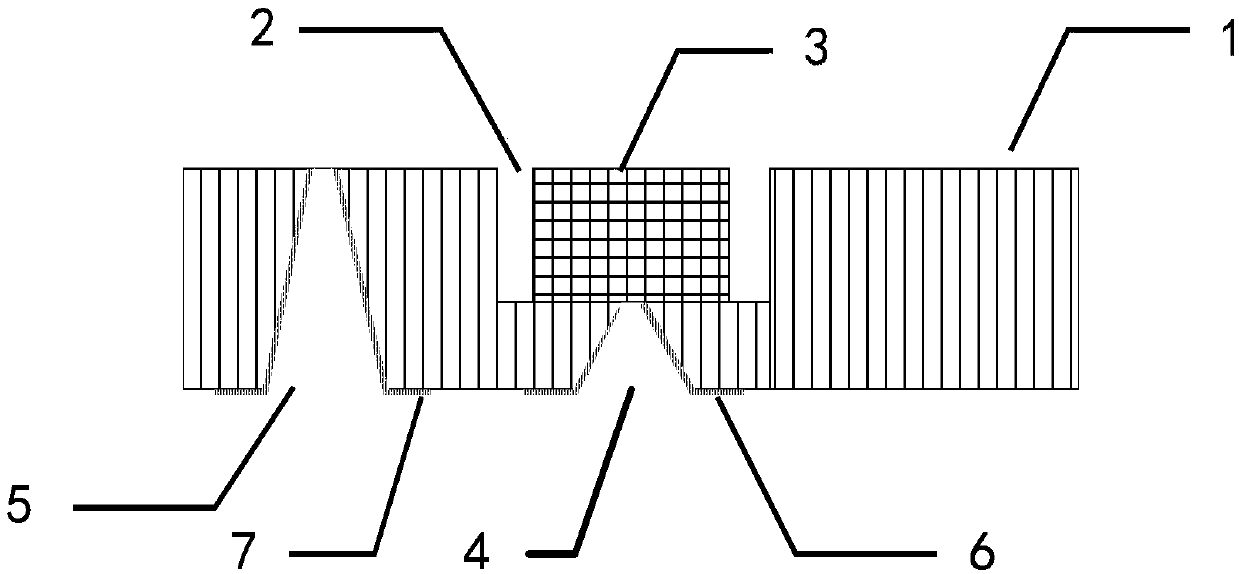

[0056] refer to figure 1 As shown, the cover plate structure shown in this embodiment includes: a sealing cover plate 1 formed of an insulating material, on which a groove 2 is provided, and the groove forms an accommodating space; an electrode plate 3 is located in the groove 2 In the formed accommodating space, there is a gap between the sealing cover plate 1 on the left and right sides of the groove 2; the first vertical through hole 4 is arranged under the electrode plate 3, and passes through the sealing cover plate 1 below the groove 2 The second vertical through hole 5 is arranged on the non-groove position of the sealing cover plate 1 and runs through the sealing cover plate 1; and the first electrode lead 6 and the second electrode lead 7 are respectively along the first vertical through hole 4 and The second vertical through h...

no. 2 example

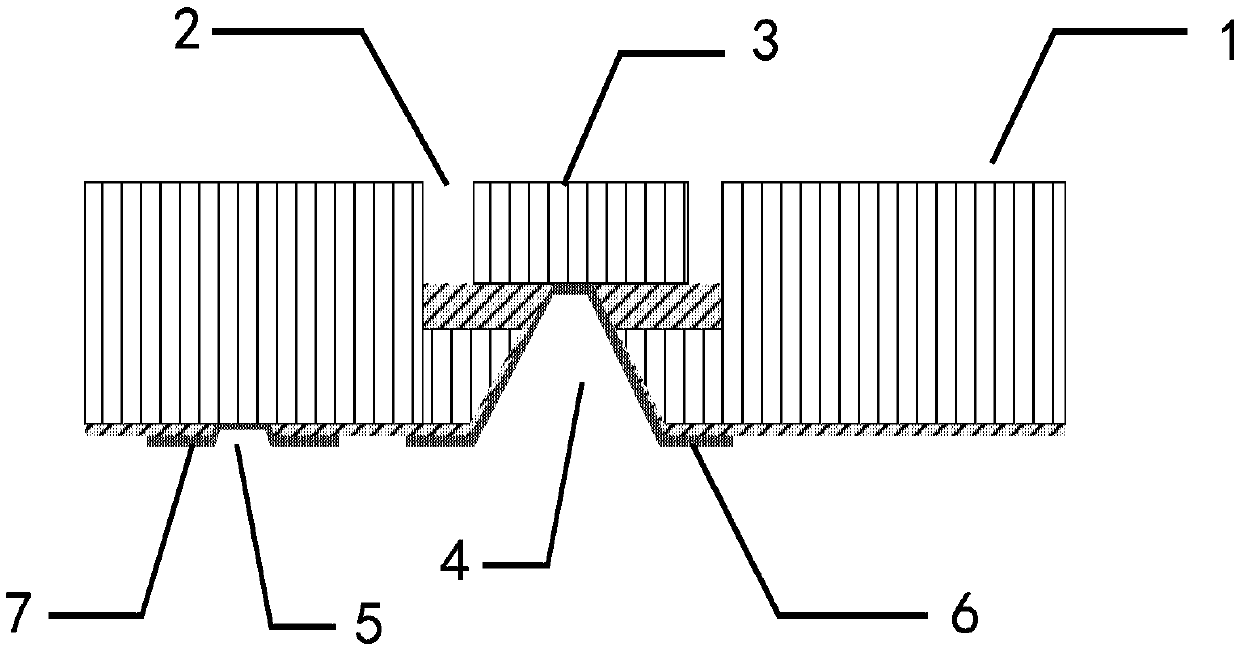

[0068] In a second embodiment of the present disclosure, there is provided a cap structure in which a semiconductor material covered with an insulating material forms a hermetic cap. Compared with the first embodiment, the structure is the same, the difference is that in the cover structure of this embodiment, the material of the sealing cover 1 is a semiconductor material covered with an insulating material, such as silicon covered with silicon oxide.

[0069] refer to figure 2 As shown, the cover plate structure shown in this embodiment includes: a sealing cover plate 1, which is provided with a groove 2, and the groove forms an accommodation space; an electrode plate 3, located in the accommodation space formed by the groove 2 Inside, there is a gap between the sealing cover plate 1 on the left and right sides of the groove 2; the first vertical through hole 4 is arranged under the electrode plate 3 and runs through the sealing cover plate 1 below the groove 2; the second ...

no. 3 example

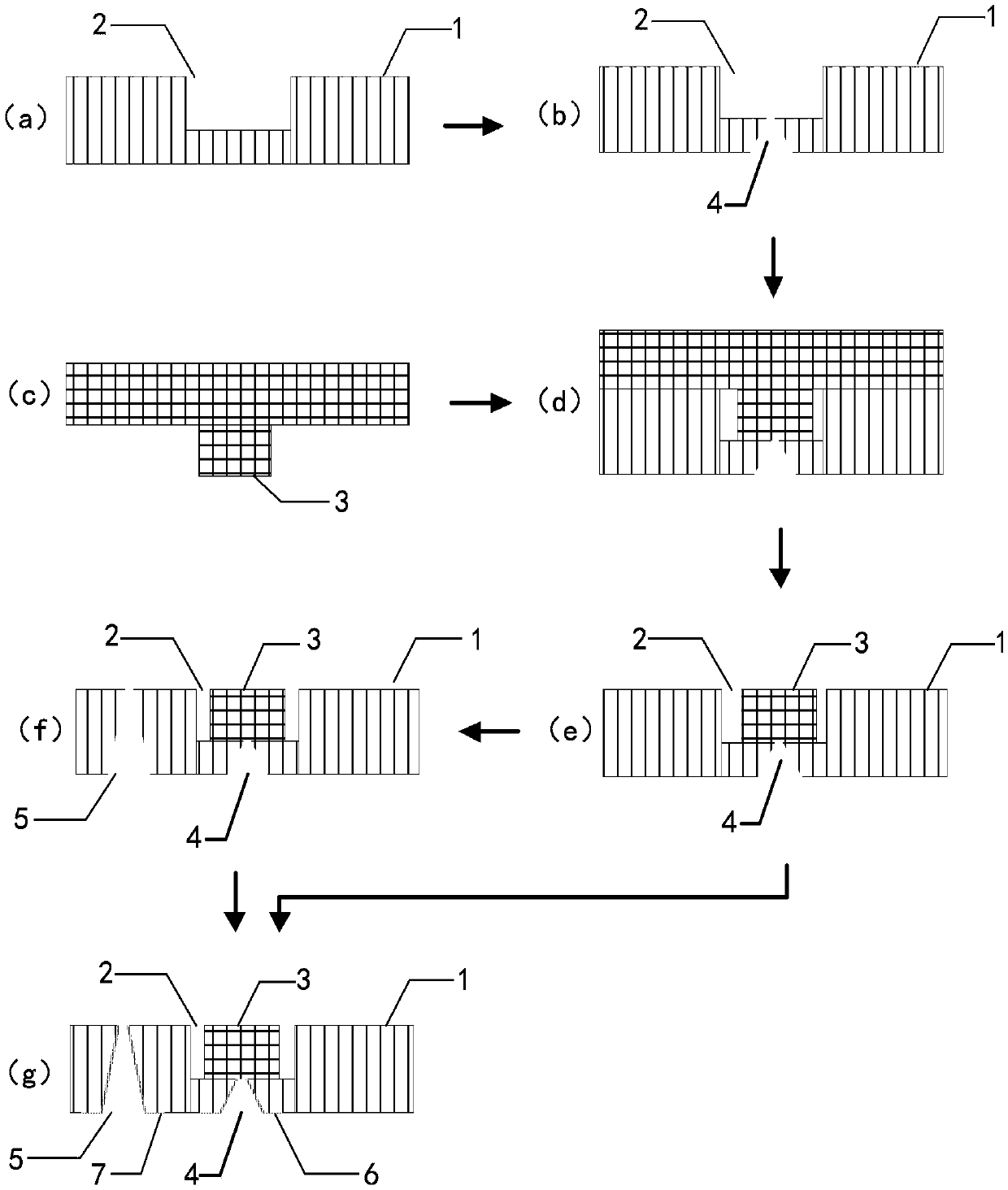

[0074] In a third embodiment of the present disclosure, a method for manufacturing the cover structure shown in the first embodiment is provided.

[0075] image 3 It is a schematic flowchart of the manufacturing method of the cover structure according to the third embodiment of the present disclosure.

[0076] refer to image 3 As shown, the manufacturing method of the cover plate structure of the present embodiment includes:

[0077] Step S31: making a groove 2 on the sealing cover plate 1 formed of insulating material, and the groove forms an accommodating space;

[0078] In this embodiment, the sealing cover plate 1 adopts a glass substrate; the upper surface of the glass substrate is patterned and etched to form a groove 2 with a certain depth, such as image 3 Shown in (a).

[0079] Wherein, the etching method is not limited to wet etching, plasma etching, electrochemical etching, etc., and may also include other patterned etching processes.

[0080] Step S32: makin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com