Method for preparing carbon-doped molybdenum sulfide/graphene oxide composite material

A composite material, molybdenum sulfide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of low purity molybdenum disulfide, harsh reaction conditions, economical The problem of high cost is to achieve the effect of simple and controllable preparation method, low cost of raw materials, and improved dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

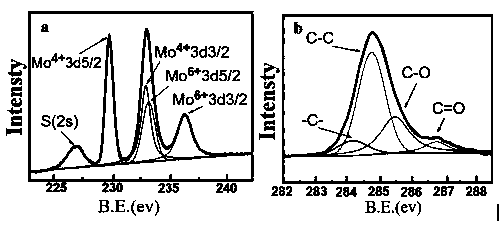

Image

Examples

Embodiment 1

[0034]A method for preparing carbon-doped molybdenum sulfide / graphene oxide composites, with (NH 4 ) 6 Mo 7 o 24 4H 2 O, graphene oxide, 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide, ethanol are raw materials, comprise the steps:

[0035] S1, prepare mixed solution: weigh 0.1236g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.0977g 1,3-bis(thioacetic acid-S-n-propyl)imidazolium bromide, 30 mg GO, add 20ml ethanol and 30ml water, sonicate until completely dissolved to form a mixed solution;

[0036] S2. Heating: Transfer the mixed solution to a 100 mL polytetrafluoroethylene reactor, and continue the reaction at 200°C for 24 hours to obtain the reactant;

[0037] S3. Cooling: After the heating is completed, the reactant is cooled to room temperature at a rate of 10°C / 10min. After each cooling, the holding time is 10min, and the product in the reactor is taken out;

[0038] S4. Separation: centrifuge the product at 8000r / min for 5min with a centrifuge, then repeatedly wash ...

Embodiment 2

[0046] The present embodiment provides a method for preparing carbon-doped molybdenum sulfide / graphene oxide composite material, with (NH 4 ) 6 Mo 7 o 24 4H 2 O, graphene oxide, 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide, ethanol are raw materials, comprise the steps:

[0047] S1, prepare mixed solution: weigh 0.1236g (NH 4 ) 6 Mo 7 o 24 4H 2 O. 0.0782g 1,3-bis(thioacetic acid-S-n-propyl)imidazolium bromide, 10 mg GO, add 20ml ethanol and 30ml water, sonicate until completely dissolved to form a mixed solution;

[0048] S2. Heating: Transfer the mixed solution to a 100 mL polytetrafluoroethylene reactor, and continue the reaction at 180°C for 12 hours to obtain the reactant;

[0049] S3. Cooling: After the heating is completed, the reactant is cooled to room temperature at a rate of 10°C / 10min. After each cooling, the holding time is 10min, and the product in the reactor is taken out;

[0050] S4. Separation: centrifuge the product at 8000r / min for 5min...

Embodiment 3

[0054] The present embodiment provides a method for preparing carbon-doped molybdenum sulfide / graphene oxide composite material, with (NH 4 ) 6 Mo 7 o 24 4H 2 O, graphene oxide, 1,3-two (thioacetic acid-S-n-propyl) imidazolium bromide, ethanol are raw materials, comprise the steps:

[0055] S1, prepare mixed solution: weigh 0.1236g (NH 4 ) 6 Mo 7 o 24 4H 2 O. 0.1954g 1,3-bis(thioacetic acid-S-n-propyl) imidazolium bromide, 10 mg GO, add 20ml ethanol and 30ml water, sonicate until completely dissolved to form a mixed solution;

[0056] S2. Heating: transfer the mixed solution to a 100 mL polytetrafluoroethylene reactor, and continue the reaction at 220°C for 18 hours to obtain the reactant;

[0057] S3. Cooling: After the heating is completed, the reactant is cooled to room temperature at a rate of 10°C / 10min. After each cooling, the holding time is 10min, and the product in the reactor is taken out;

[0058] S4. Separation: centrifuge the product at 8000r / min for 5mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com