Non-noble metal acetylene selective hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and non-precious metal technology, applied in the field of non-precious metal acetylene selective hydrogenation catalyst and its preparation, can solve the problems of high price of precious metal palladium, poor ethylene selectivity, poor stability, etc. The effect of efficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

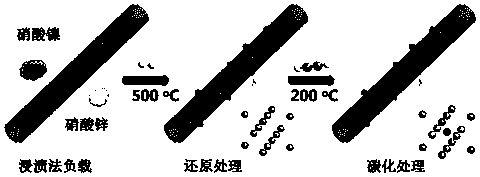

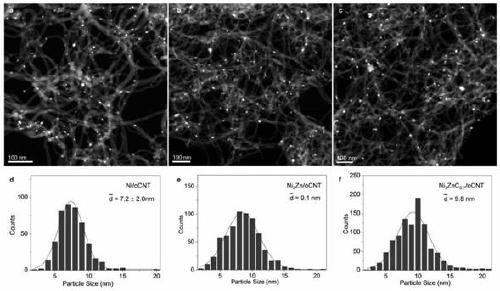

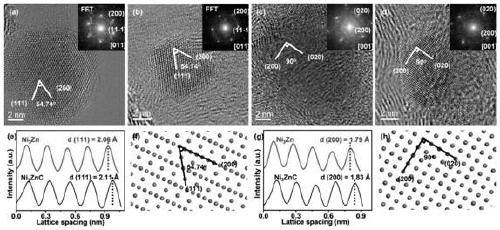

[0028] This embodiment prepares supported Ni 3 ZnC 0.7 The catalyst process is as follows:

[0029] 1. Carbon nanotubes are first added to concentrated hydrochloric acid (37wt.%) with a feed ratio of 1g:100ml, and stirred at room temperature for 24 hours to remove residual metals; then carbon nanotubes are added to concentrated nitric acid with a feed ratio of 1g:100ml (68wt.%), reflux at 140°C for 2 hours, filter and wash until neutral to obtain oxidized carbon nanotubes (oCNT).

[0030] 2. Immersion method: Dissolve 101mg of nickel nitrate hexahydrate and 33.7mg of zinc nitrate hexahydrate in 40ml of ethanol, then add 374mg of carbon dioxide nanotubes, stir ultrasonically for about 1 hour to ensure uniform dispersion, and then remove by rotary evaporator Solvent ethanol, keep warm in oven at 100°C for 2 hours.

[0031]3. The sample treated in step 2 is subjected to reduction treatment in a mixed atmosphere of hydrogen and argon, the flow rate of the mixed gas is 100ml / min...

Embodiment 2

[0040] The Ni prepared by embodiment 1, comparative example 1-2 3 ZnC 0.7 Catalyst, Ni 3 Zn / oCNT catalysts and Ni / oCNT catalysts are used in the selective hydrogenation of acetylene. The application process is as follows:

[0041] Take Ni / oCNT, Ni / oCNT, Ni 3 Zn / oCNT and Ni 3 ZnC 0.7 The / oCNT catalyst is added into the quartz reaction tube, and the catalyst is fixed in the middle constant temperature area of the reaction bed through quartz wool.

[0042] Firstly, pretreatment is carried out: the mixed gas of hydrogen and helium (hydrogen 50vol.%) is passed into the reaction tube, and the catalyst is used for reduction at 500°C for 2 hours, and the gas flow rate is controlled by a mass flow meter to be 20mL / min.

[0043] After pretreatment, it is lowered to 200°C, and then the catalyst performance is tested, specifically: the gas composition of acetylene hydrogenation reaction is: 1.5~6.0vol.%H 2 , 20vol.%C 2 h 4 , 0.5vol.%C 2 h 2 , Helium as the balance gas. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com