Hydrophilic modification method of high-flux PVDF porous membrane

A porous membrane and hydrophilization technology, applied in the field of membrane materials, can solve the problems of incomplete dispersion, affect the modification effect, uneven liquid phase of the casting liquid, etc., and achieve the effect of good hydrophilic performance and large flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

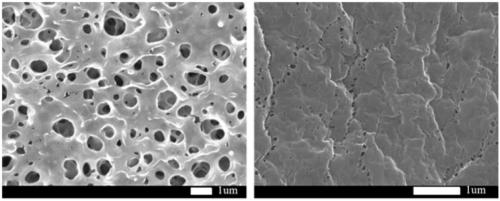

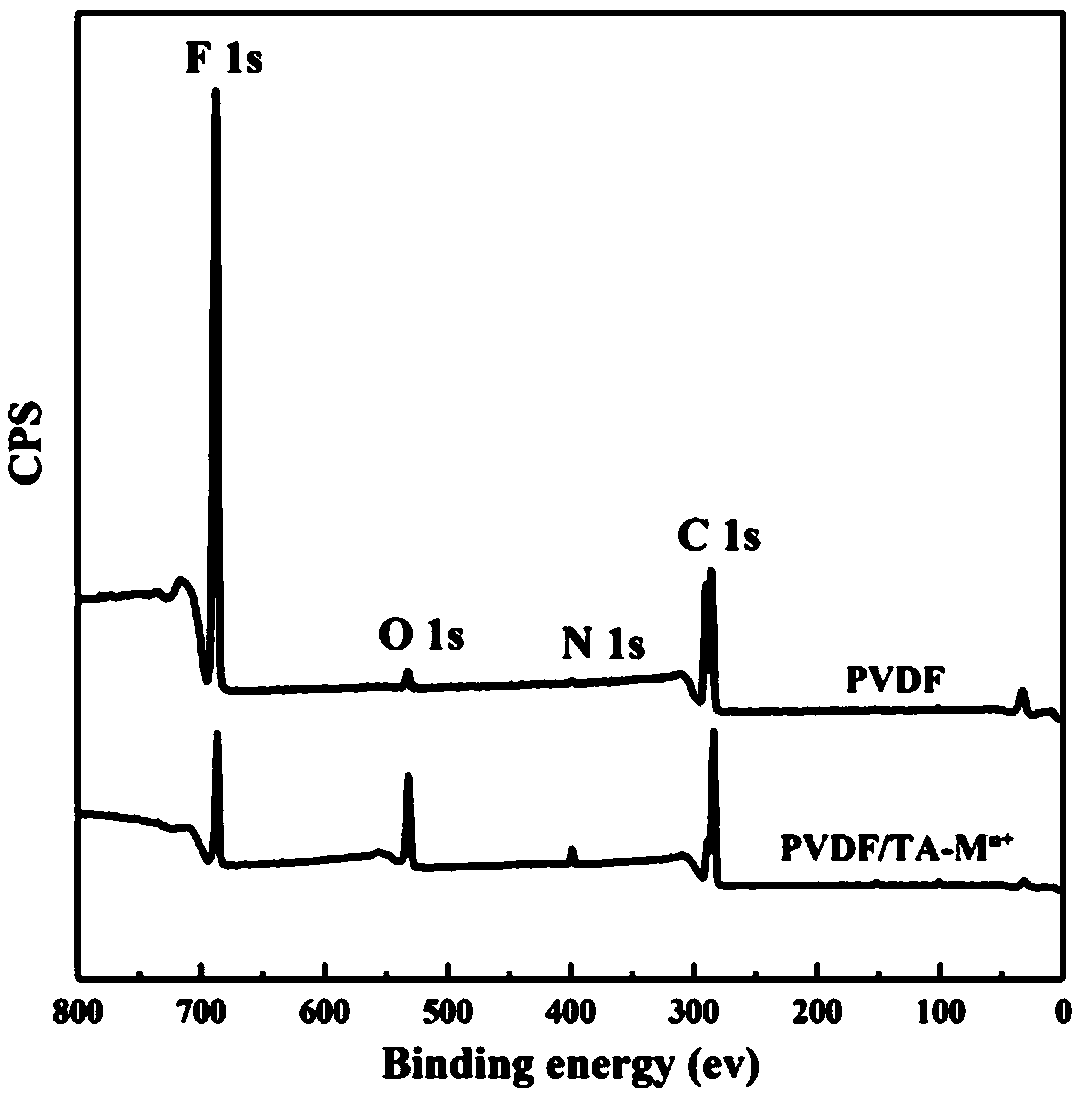

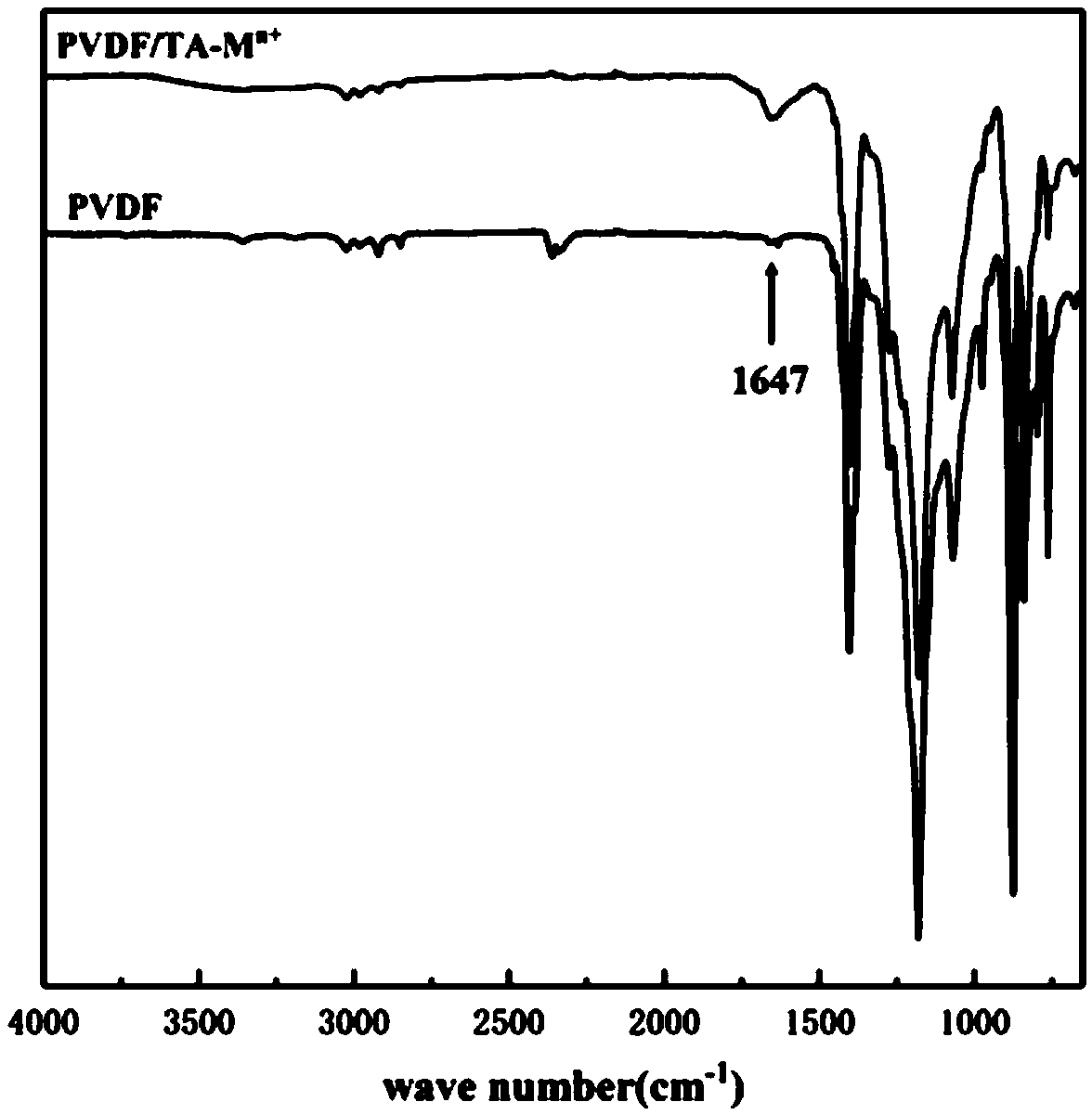

[0026] Weigh 15g PVDF powder, 1g porogen PVP, 0.75g tannin and 83.25g organic solvent DMF. Add the weighed organic solvents DMF and tannin to the three-necked flask, and place the three-necked flask in a constant temperature water bath at 40°C for 10 minutes. Then add PVDF powder and porogen PVP into the three-necked flask, stir and react for 24h to obtain a uniform, Stable casting liquid. Place the casting solution in a vacuum drying oven at 50° C., and defoam for 12 hours to fully discharge the bubbles in the casting solution. Pour the casting solution on a clean glass plate, scrape out a flat film with a uniform thickness with a 100μm thick film knife, and immediately put the glass plate into a 20℃, 0.04mol / L iron ion aqueous solution (pH= 6. In other embodiments, the pH is between 5-6). After the film is formed and the film is automatically separated from the glass plate, continue to soak in the above coagulation solution for 5 hours to ensure that the film structure is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com