Composite protein gel and preparation method thereof

A composite protein and gel technology, which is applied in the field of composite protein gel and its preparation, can solve the problems of poor stability of fillers, stiff skin, high absorption rate, etc., and achieve long maintenance time, small immune rejection and strong regenerative ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

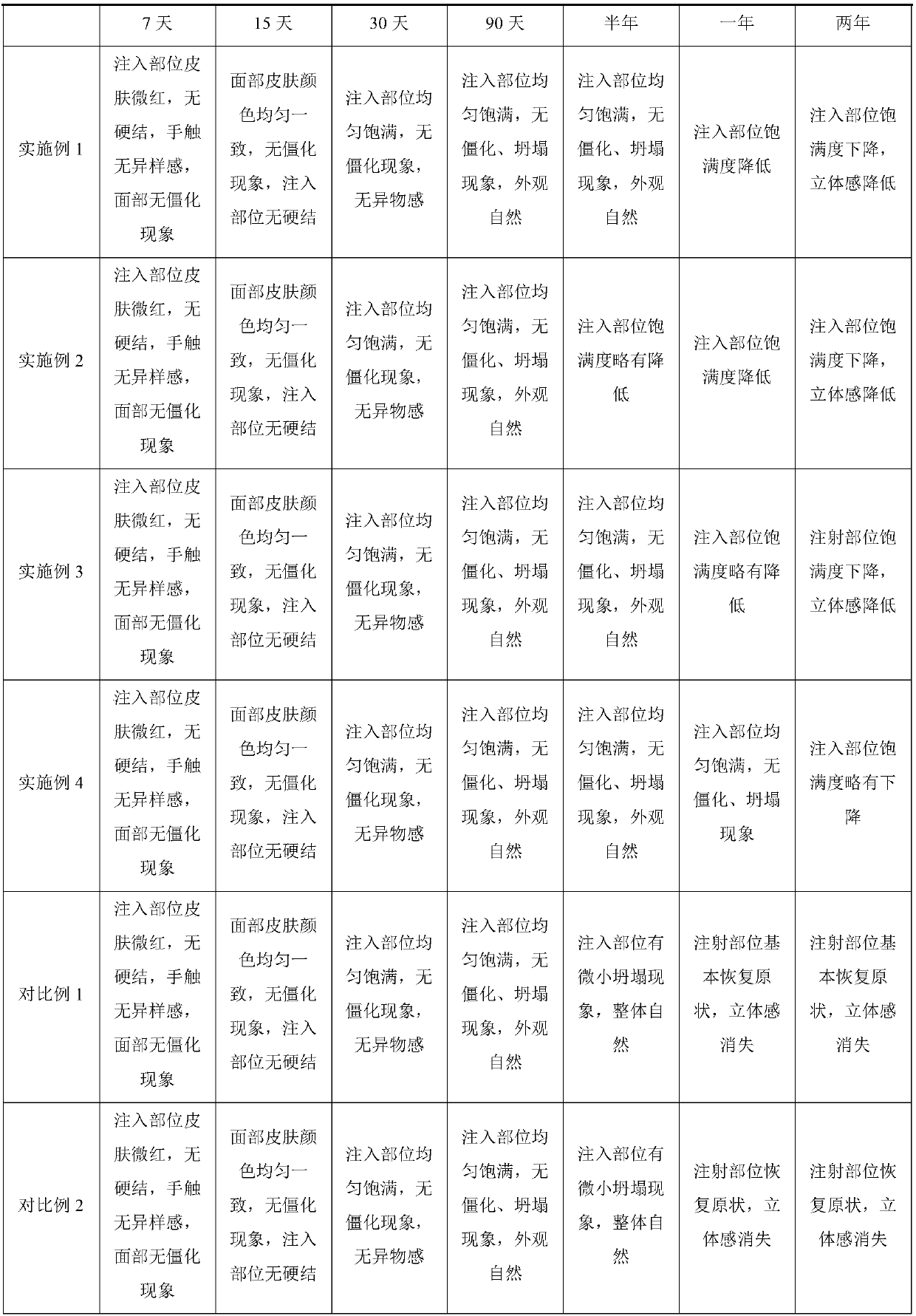

Examples

Embodiment 1

[0027] A kind of composite protein gel, its preparation method, comprises the following steps:

[0028] (1) Collect umbilical cord blood with a blood collection tube with 3.8% sodium citrate anticoagulant, and the volume ratio of sodium citrate to umbilical cord blood is 1:13;

[0029] (2) centrifuging the umbilical cord blood in step (1) at room temperature with a centrifugal acceleration of 300g for 10min;

[0030] (3) absorb the upper plasma layer in the centrifuged blood in step (2), and place it in an ultra-low temperature refrigerator at -80° C. for rapid freezing, and the freezing time is 24 hours;

[0031] (4) The plasma frozen in step (3) is taken out, and freeze-dried at a temperature of -55° C. and a pressure of 50 Pa to obtain freeze-dried plasma;

[0032] (5) Mix the freeze-dried plasma prepared in step (4) with calcium chloride injection at a concentration of 20 μmol / L at a volume ratio of 1:0.5, then react in a water bath at 60°C for 5 minutes, and take it out ...

Embodiment 2

[0034] A kind of composite protein gel, its preparation method, comprises the following steps:

[0035] (1) Collect autologous venous blood with a blood collection tube with 3.8% sodium citrate anticoagulant, and the volume ratio of sodium citrate to autologous venous blood is 1:13;

[0036] (2) centrifuging the autologous venous blood in step (1) at room temperature with a centrifugal acceleration of 700g for 20min;

[0037] (3) absorb the upper plasma layer in the centrifuged blood in step (2), and place it in an ultra-low temperature refrigerator at -80° C. for rapid freezing, and the freezing time is 72 hours;

[0038] (4) The plasma frozen in step (3) is taken out, and freeze-dried at a temperature of -65° C. and a pressure of 100 Pa to obtain freeze-dried plasma;

[0039] (5) Mix the freeze-dried plasma prepared in step (4) with calcium chloride injection at a concentration of 50 μmol / L at a volume ratio of 1:2, then react in a water bath at 90° C. for 15 minutes, and t...

Embodiment 3

[0041] A method for preparing a composite protein gel, comprising the following steps:

[0042] (1) Collect umbilical cord blood with a blood collection tube with 3.8% sodium citrate anticoagulant, and the volume ratio of sodium citrate to umbilical cord blood is 1:13;

[0043] (2) centrifuging the umbilical cord blood in step (1) at room temperature with a centrifugal acceleration of 500g for 15min;

[0044] (3) Absorb the upper plasma layer in the centrifuged blood in step (2), and place it in an ultra-low temperature refrigerator at -80° C. for rapid freezing, and the freezing time is 48 hours;

[0045] (4) The plasma frozen in step (3) is taken out, and freeze-dried at a temperature of -65° C. and a pressure of 70 Pa to obtain freeze-dried plasma;

[0046] (5) Mix the freeze-dried plasma prepared in step (4) with calcium chloride injection at a concentration of 30 μmol / L at a volume ratio of 1:1.5, then react in a water bath at 80°C for 10 minutes, and take it out to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com