LED (Light Emitting Diode) driving circuit based on power tube safety protection

A technology of LED drive and drive circuit, applied in the field of LED drive, can solve the problems of power tube burnout, lack of control of power tube drain current, rise of power tube drain current, etc., and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

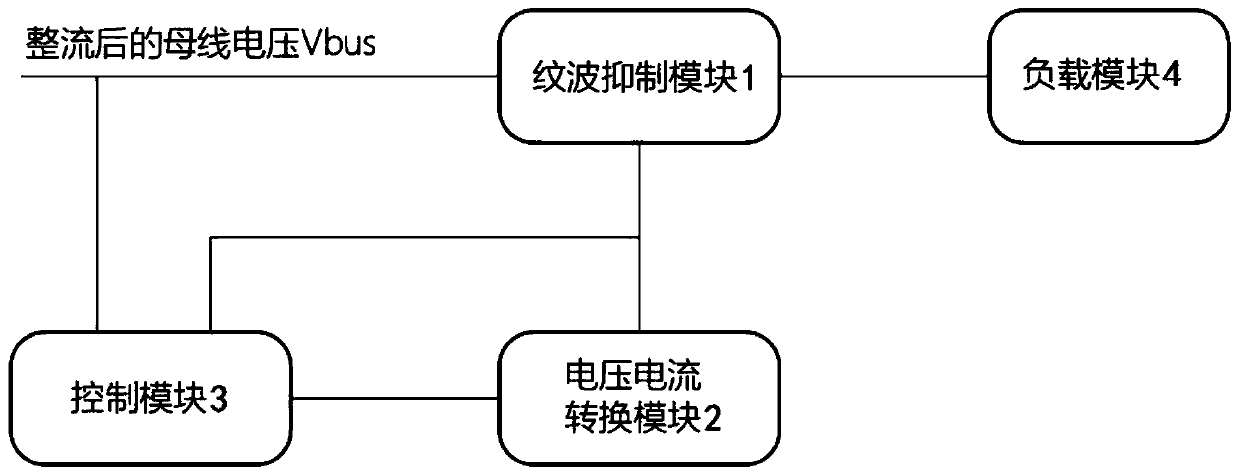

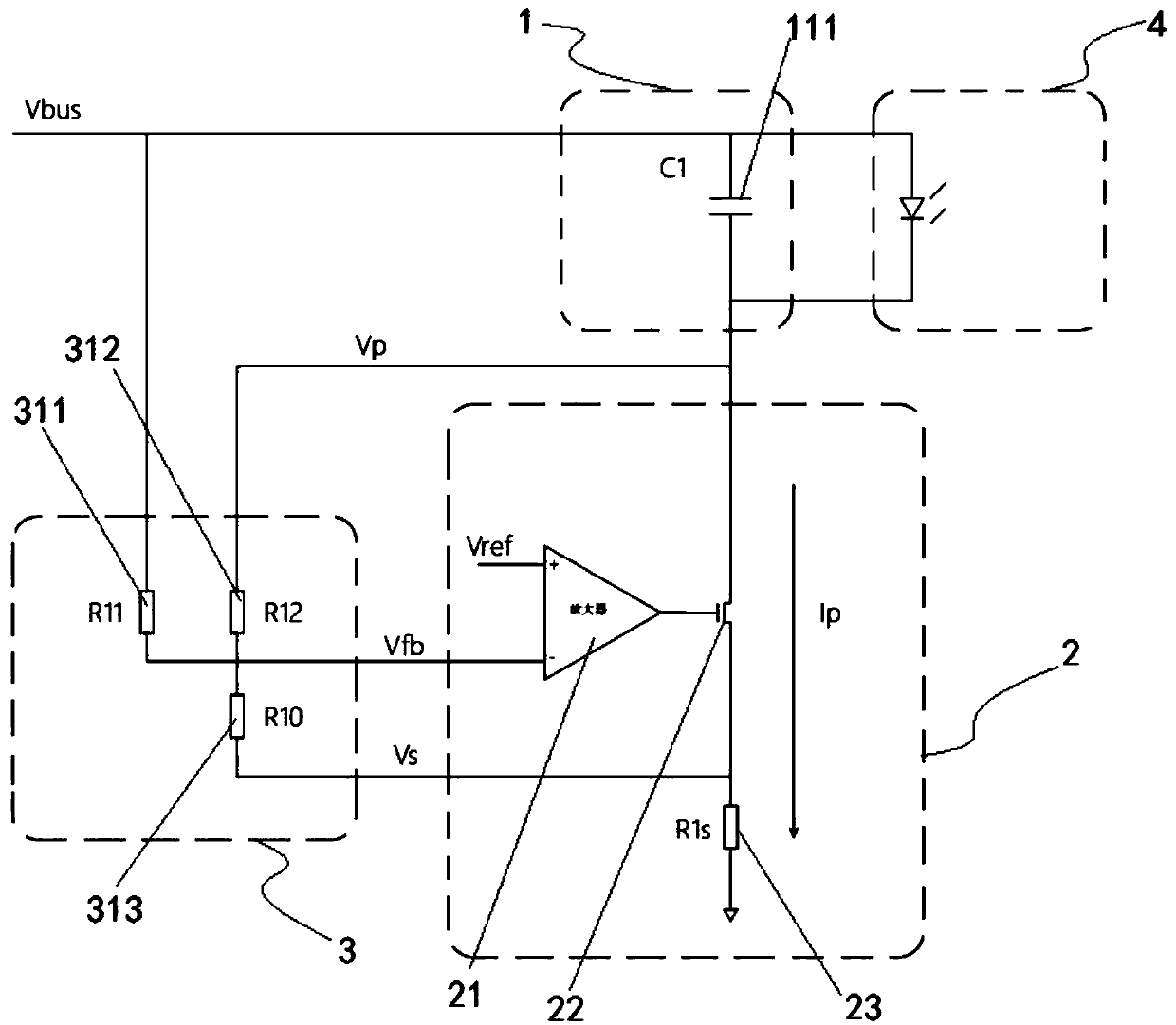

[0042]In one embodiment of the present invention, a LED drive circuit based on power tube safety protection is provided, such as image 3 As shown, the ripple suppression module 1 of the drive circuit includes a first capacitor 111, the positive pole of the first capacitor 111 is connected to the bus bar of the power distribution device, and the negative pole of the first capacitor 111 is connected to the input end of the power transistor 22, so The load 4 is connected in parallel to both ends of the first capacitor 111, and the first capacitor 111 suppresses the current ripple of the load module.

[0043] The control module 3 of the drive circuit includes a first resistor 311 (hereinafter referred to as R11), a second resistor 312 (hereinafter referred to as R12) and a third resistor 313 (hereinafter referred to as R10), and the first resistor 311 is set at between the bus bar of the power distribution device and the inverting input terminal of the amplifier 21; the second re...

Embodiment 2

[0049] In one embodiment of the present invention, a LED drive circuit based on power tube safety protection is provided, such as Figure 4 As shown, the ripple suppression module 1 of the drive circuit includes a first capacitor 111, the positive pole of the first capacitor 111 is connected to the bus bar of the power distribution device, and the negative pole of the first capacitor 111 is connected to the input end of the power transistor 22, so The load 4 is connected in parallel to both ends of the first capacitor 111, and the first capacitor 111 suppresses the current ripple of the load module.

[0050] The control module 3 of the drive circuit includes a first transconductance amplifier 321, a first constant current source 322, a grounding capacitor 323, a fourth resistor 324 (hereinafter referred to as R21) and a fifth resistor 325 (hereinafter referred to as R20), so The output end of the first constant current source 322, the output end of the first transconductance a...

Embodiment 3

[0058] In one embodiment of the present invention, a LED drive circuit based on power tube safety protection is provided, such as Figure 5 As shown, the ripple suppression module 1 of the driving circuit includes a second capacitor 121, a third capacitor 122, a voltage dividing resistor 123, a third constant current source 124, and a second power tube 125. The anode of the second capacitor 121 is connected to the The power distribution device is connected to the bus bar, the load 4 is connected in series with the voltage dividing resistor 123 and the third constant current source 124 to form a branch circuit, the branch circuit is connected in parallel with the second capacitor 121, and the third capacitor 122 is connected to the first Three constant current sources 124 are connected in parallel, and the drain and source of the second power transistor 125 are connected in parallel to the two ends of the voltage dividing resistor 123 and the third constant current source 124, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com