A high-temperature formation process for high-voltage polymer lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

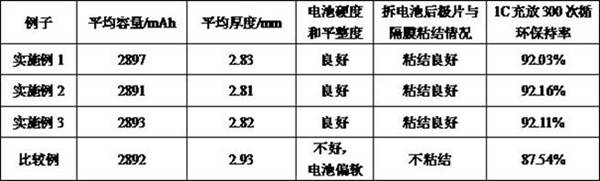

Embodiment 1

[0021] In an embodiment of the present invention, a high-temperature formation process of a high-voltage polymer lithium-ion battery includes the following steps:

[0022] (1) The high-voltage polymer lithium-ion battery made of ceramic separator and filled with electrolyte is placed at a high temperature of 45°C for 8 hours; this high-temperature standing can fully obtain the electrolyte in the pole piece and separator infiltration;

[0023] (2) Put the battery in a high-temperature pressure forming machine, and bake it continuously for 2 hours at a pressure of 0.6MpaMpa and a temperature of 75°C;

[0024] (3) Cool down the temperature of the high-temperature pressure forming machine to 60°C and then form the battery under the pressure of 0.2Mpa according to the formation process;

[0025] (4) After the formation, heat up the high-temperature pressure formation machine to 75°C and continue baking under the pressure of 0.6Mpa for 2 hours;

[0026] (5) Cool down the high temp...

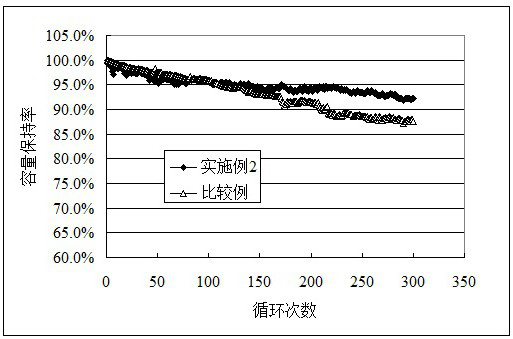

Embodiment 2

[0030] In an embodiment of the present invention, a high-temperature formation process of a high-voltage polymer lithium-ion battery includes the following steps:

[0031] (1) The high-voltage polymer lithium-ion battery made of ceramic separator and filled with electrolyte is placed at a high temperature of 45°C for 10 hours; infiltration;

[0032] (2) Put the battery in a high-temperature pressure forming machine, and bake it continuously for 2.5 hours at a pressure of 0.8Mpa and a temperature of 80°C;

[0033] (3) Cool down the temperature of the high-temperature pressure formation machine to 65°C and then form the battery under the pressure of 0.3Mpa according to the formation process;

[0034] (4) After the formation, heat up the high-temperature pressure formation machine to 80°C and continue baking under the pressure of 0.8Mpa for 2 hours;

[0035] (5) Cool down the high temperature pressure forming machine to room temperature and then take out the battery to complete...

Embodiment 3

[0039] In an embodiment of the present invention, a high-temperature formation process of a high-voltage polymer lithium-ion battery includes the following steps:

[0040] (1) The high-voltage polymer lithium-ion battery made of ceramic separator and filled with electrolyte is placed at a high temperature of 45°C for 12 hours; infiltration;

[0041] (2) Put the battery in a high-temperature pressure formation machine, and bake it continuously for 3 hours at a pressure of 1.0Mpa and a temperature of 85°C;

[0042] (3) Cool down the high-temperature pressure forming machine to 70°C and then form the battery under the pressure of 0.4Mpa according to the formation process;

[0043] (4) After the formation, heat up the high-temperature pressure formation machine to 85°C and continue baking at a pressure of 1.0Mpa for 2 hours;

[0044] (5) Cool down the high temperature pressure forming machine to room temperature and then take out the battery to complete the high temperature form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com