Domestic garbage recycling device

A technology for domestic garbage and garbage, applied in the field of domestic garbage recycling devices, can solve the problems of low crushing efficiency, storage and crushing, unreasonable occupation of the internal space of the recycling box, etc., so as to improve the recycling efficiency and reduce the space occupied by recycling. , The effect of facilitating the recycling and transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

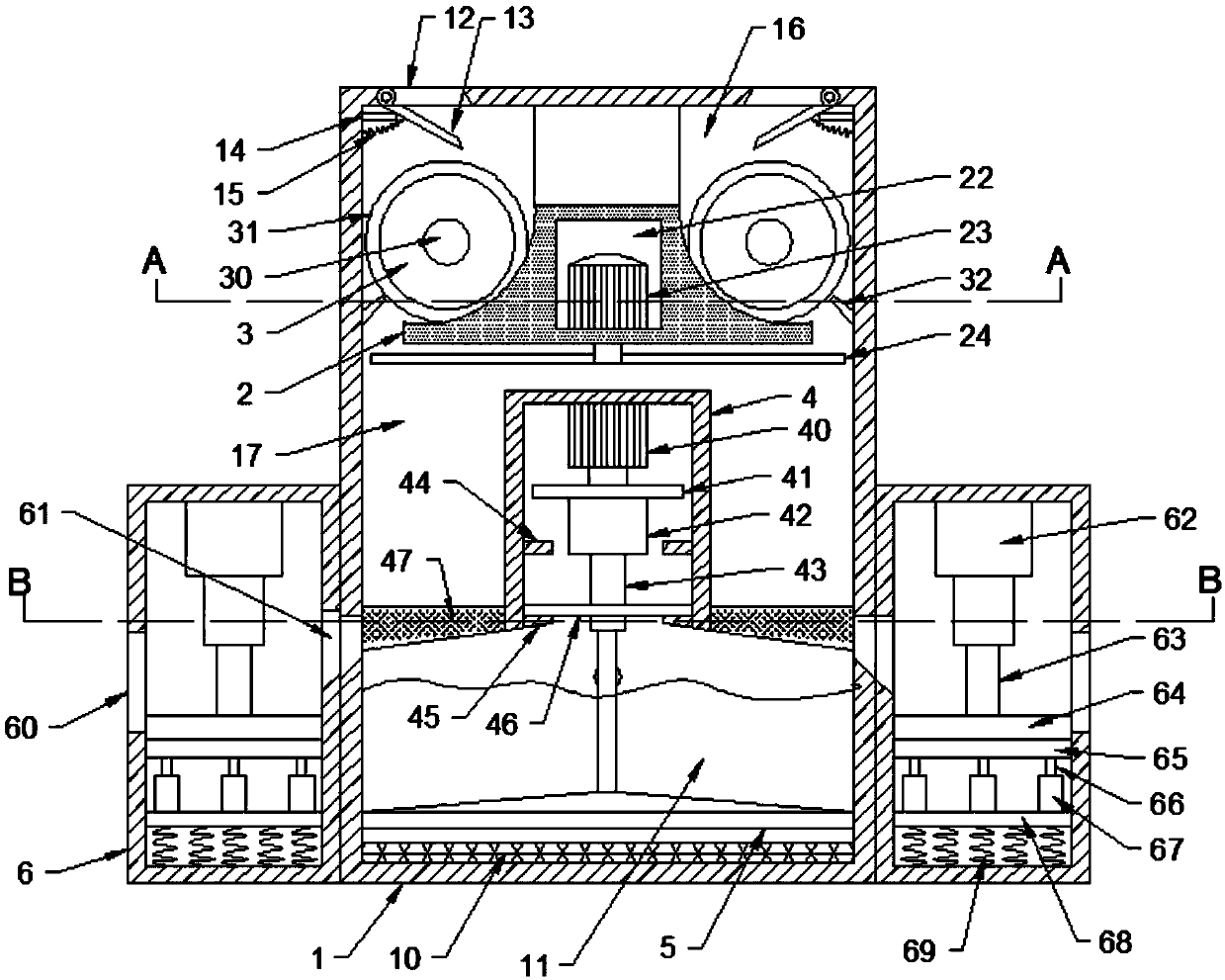

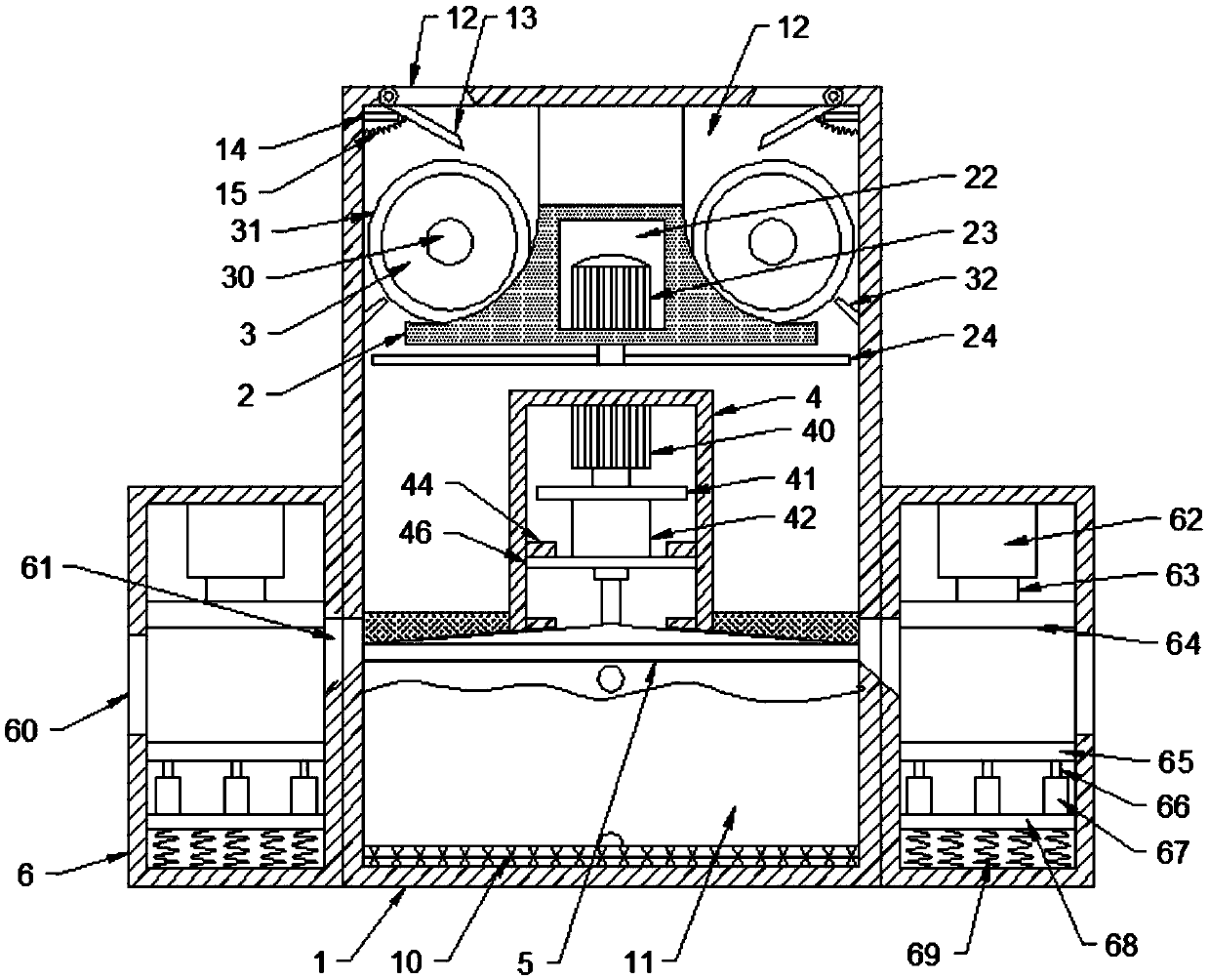

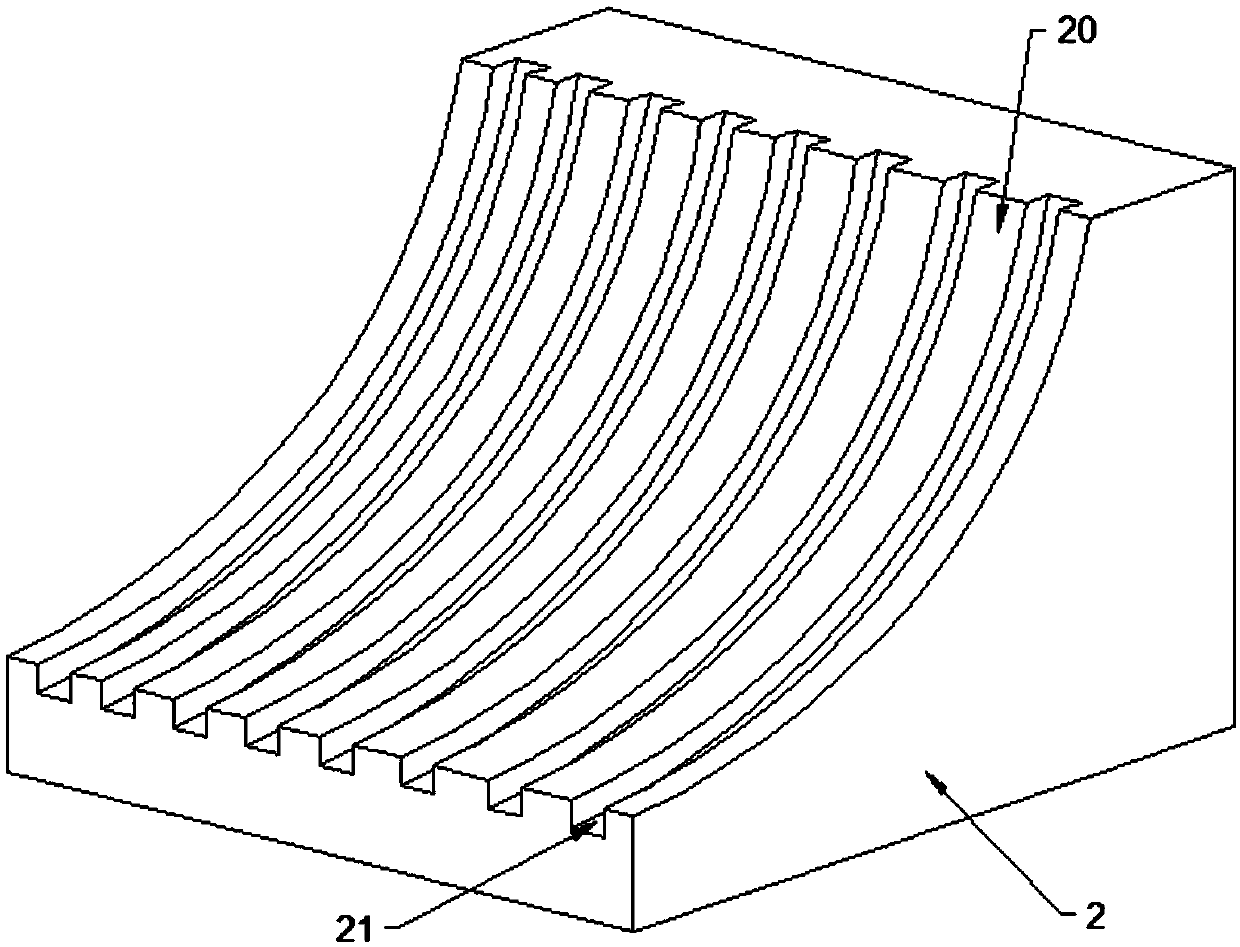

[0026] see Figure 1-7 , in the embodiment of the present invention, a domestic garbage recycling device includes a processing box 1, and the interior of the processing box 1 is provided with a cutting cavity 16, a blanking cavity 17 and a soaking cavity 11 in sequence from top to bottom. , the cutting cavity 16, the blanking cavity 17 and the soaking cavity 11 are connected to each other, the left and right sides of the top surface of the processing box 1 are provided with a feeding port 12 for putting in paper garbage, and the blanking cavity 17 is provided with a For the cutting and crushing device for crushing paper waste, the feeding port 12 is equipped with a protective cover 13 that is lifted up through the return spring 15, and the protective cover 13 is provided with a limiter to limit the turning angle of the protective cover 13. Bit block 14, the feeding port 12 communicates with the blanking chamber 17, the cutting and crushing device includes a pressing device for...

Embodiment 2

[0035] The bottom of the material receiving plate 65 is provided with a shaking device for paving the pulp on the top surface of the material receiving plate 65, and the shaken paper is formed by three shaking electric telescopic rods 67 distributed on the bottom of the material receiving plate 65 on the circumference. Composition, the telescoping end of described shaking electric telescopic rod 67 is fixed shaking even lifting rod 66 , and the top end of described shaking even lifting rod 66 is fixed on the bottom surface of receiving plate 65 .

[0036] The bottom of described recovery box 6 is provided with buffering device, and described buffering device comprises buffering bottom plate 68 and buffering spring 69, and described buffering bottom plate 68 is arranged on the inner bottom surface top of recovery box 6, and the bottom surface of buffering bottom plate 68 and recycling box There are many buffer springs 69 fixed between the inner bottom surfaces of 6 .

[0037] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com