Compounding formula of nano aluminum oxide powder surface modifier

A technology of powder surface modification and nano-alumina, applied in the field of surface modifier compound formulation, can solve problems such as uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

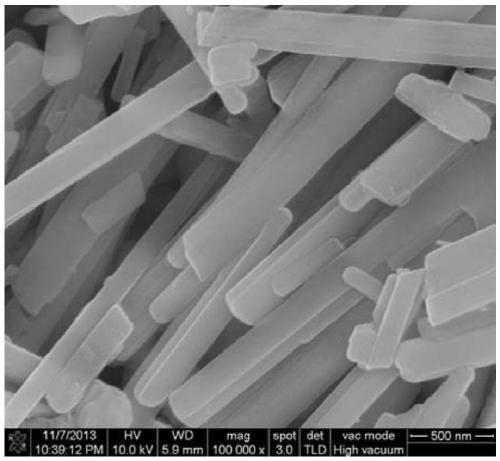

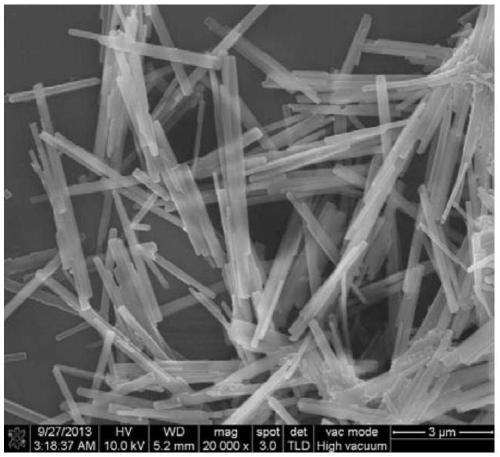

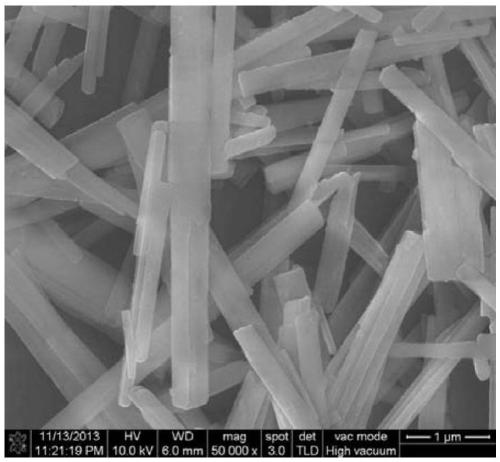

[0013] A compound formulation of nano-alumina powder surface modifier described in Example 1, including polyethylene glycol PEG-6000 and sodium dodecylbenzenesulfonate SDBS, polyethylene glycol in the monomolecular adsorption layer The mole fractions of alcohol PEG-6000 and sodium dodecylbenzenesulfonate SDBS are the same, and the interaction parameters of polyethylene glycol PEG-6000 and sodium dodecylbenzenesulfonate SDBS in the monomolecular adsorption layer are 2.72-2.77 , the micelle concentration of sodium dodecylbenzenesulfonate SDBS is 0.0012mol / L. PEG is a water-soluble polymer and cannot form micelles, so in the mixed solution, only SDBS forms micelles. As the concentration of PEG increases, the CMC required to form SDBS micelles decreases. like figure 1 As shown, when the formulation of polyethylene glycol PEG-6000 and sodium dodecylbenzene sulfonate SDBS is used for reaction, the morphology and characteristics of the product can be effectively improved.

[0014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com