Hybrid material manhole cover and manufacturing method thereof

A hybrid material, inspection well technology, applied in hydraulic engineering, artificial islands, underwater structures, etc., can solve the problems of load reduction, difficult to widely apply and popularize, easy to peel, etc., and achieve small change in elongation at break, Improve physical and mechanical properties and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

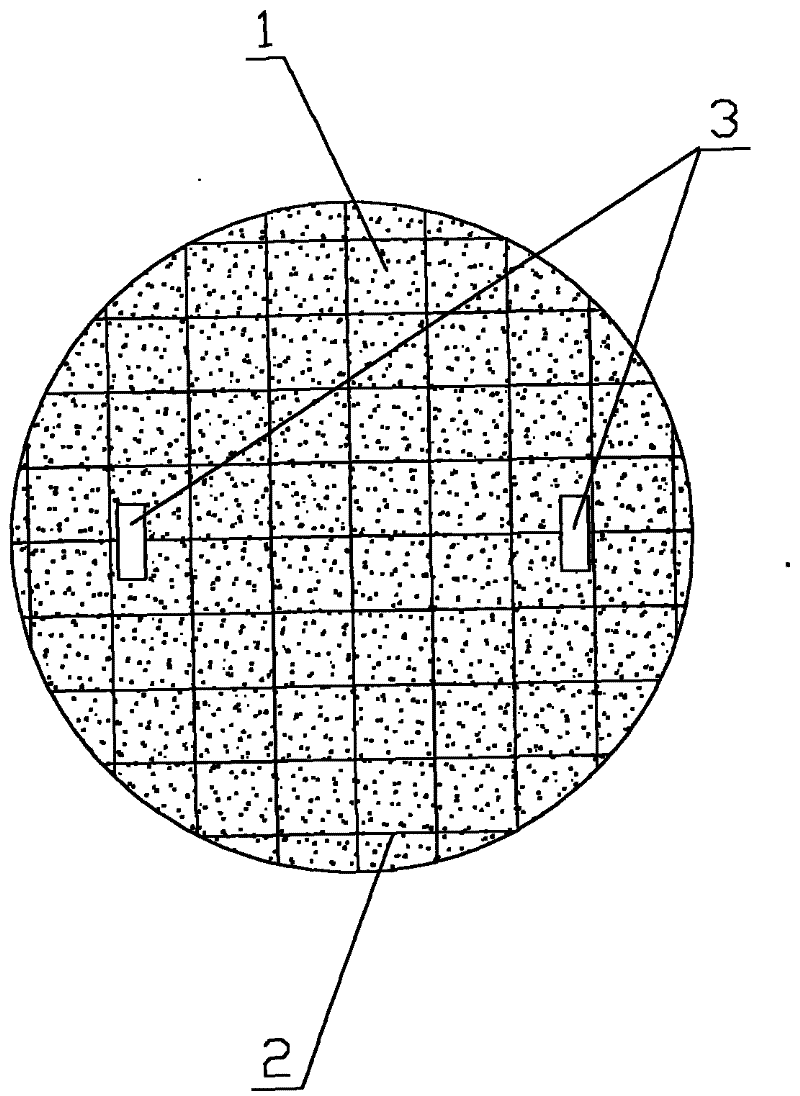

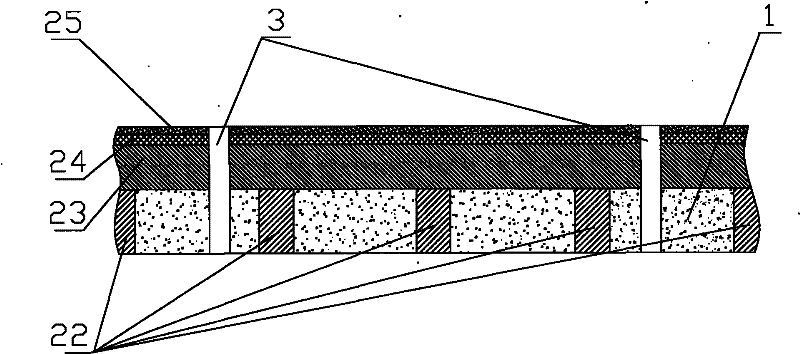

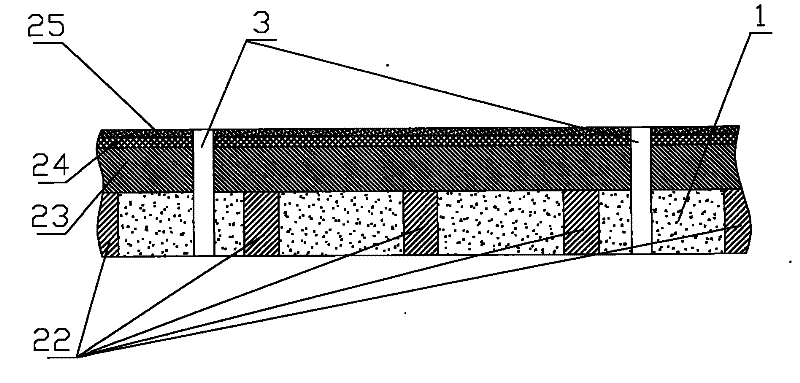

[0022] As an embodiment of the present invention, such as figure 1 and figure 2 As shown, a hybrid material inspection manhole cover includes a manhole cover and a support that matches the manhole cover. The manhole cover and the support are covered with a hybrid material 1 to fill the skeleton 2 and the support skeleton, and are vibrated and solidified by a vibration mold machine. Released from the mold. The hybrid material 1 includes 20%-26% modified unsaturated resin, 32%-40% quartz sand, 37%-39% gravel, and 3% chopped and ultra-short Cut fiber, curing agent and filler are mixed and stirred. The modified unsaturated resin can be unsaturated polyester resin 191; the quartz sand can be 100-300 mesh quartz sand; the chopped fiber can be S glass or E glass with a chopped length of 50mm, ultra-short The cut fiber can be S glass or E glass with a chopped length of 3.2-12.7mm, polypropylene fiber and nylon yarn; the curing agent can be potassium peroxide ethyl ketone, cyclohex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com