Water-based stone-crash-resistant blocked polyisocyanate curing agent as well as preparation method thereof and water-based coating

A polyisocyanate, isocyanate trimerization technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as environmental pollution, increase production costs, etc., and achieve improved stone chip resistance, low VOC emissions, and simple synthesis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

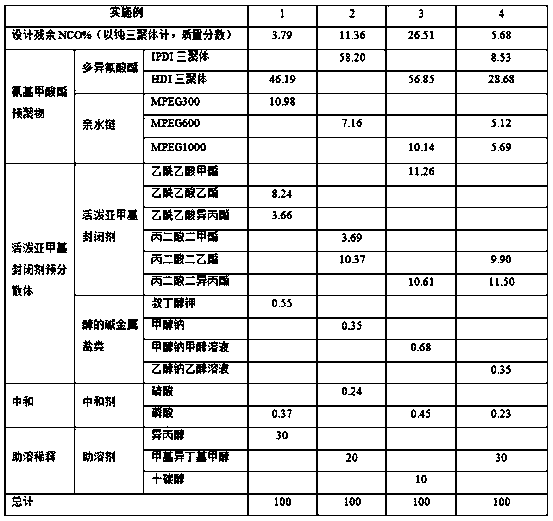

Embodiment 1

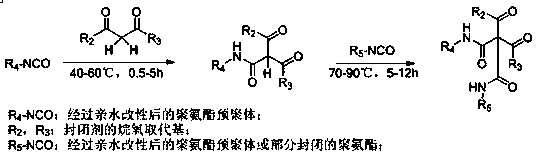

[0056] (1) Put the hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG300) in a four-neck round bottom flask, insert a thermometer, then turn on the oil pump, and remove water under reduced pressure (negative pressure is 750mmHg, temperature is 99°C, time 4h), the endpoint controls the water content of the hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG300) to 0.07%, and cools to 40°C.

[0057] (2) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on the above-mentioned four-necked round-bottom flask. Under stirring, add ethyl acetate and HDI trimer polyisocyanate, and blow in nitrogen at the same time, and disperse for 15 minutes. Then the temperature was raised to 95°C, the blowing of nitrogen gas was stopped, and the reaction was carried out for 2 hours to obtain a urethane prepolymer.

[0058] (3) Alkali metal salts of alcohols (potassium tert-butoxide) and active methylene blocking agents (ethyl acetoaceta...

Embodiment 2

[0062] (1) Put the hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG600) in a four-neck round bottom flask, insert a thermometer, then turn on the oil pump, and remove water under reduced pressure (negative pressure is 760mmHg, temperature is 105°C, time 3h), the water content of the endpoint control hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG600) is 0.05%, and cooled to 40°C.

[0063] (2) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on the above-mentioned four-necked round-bottom flask. Under stirring, add ethyl acetate and IPDI trimer polyisocyanate, and blow in nitrogen at the same time, and disperse for 15 minutes. Then the temperature was raised to 95° C., the blowing of nitrogen gas was stopped, and the reaction was carried out for 1.5 hours to obtain a urethane prepolymer.

[0064] (3) Alkali metal salts of alcohols (sodium methoxide) and active methylene blocking agents (dimethyl malonate and...

Embodiment 3

[0068] (1) Put the hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG1000) in a four-necked round bottom flask, insert a thermometer, then turn on the oil pump, and remove water under reduced pressure (negative pressure is 755mmHg, temperature is 100°C, time 3.5h), the water content of the end-point control hydrophilic chain alcohol (polyethylene glycol monomethyl ether MPEG1000) is 0.06%, and cooled to 40°C.

[0069] (2) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on the above-mentioned four-necked round-bottom flask. Under stirring, add ethyl acetate and HDI trimer polyisocyanate, and blow in nitrogen at the same time, and disperse for 15 minutes. Then the temperature was raised to 95°C, the blowing of nitrogen gas was stopped, and the reaction was carried out for 2.5 hours to obtain a urethane prepolymer.

[0070] (3) Pre-disperse alkali metal salts of alcohols (sodium methoxide in methanol) and active methylene blocking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com