High-water-resistance alkyl ketene dimer (AKD) emulsion and preparation method thereof

An emulsion and high-resistance technology, applied in the field of papermaking, can solve the problems of wasting water resources and energy, low solid content of the emulsion, and low sizing efficiency, and achieve the effects of simplifying the process, excellent water resistance, and high sizing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

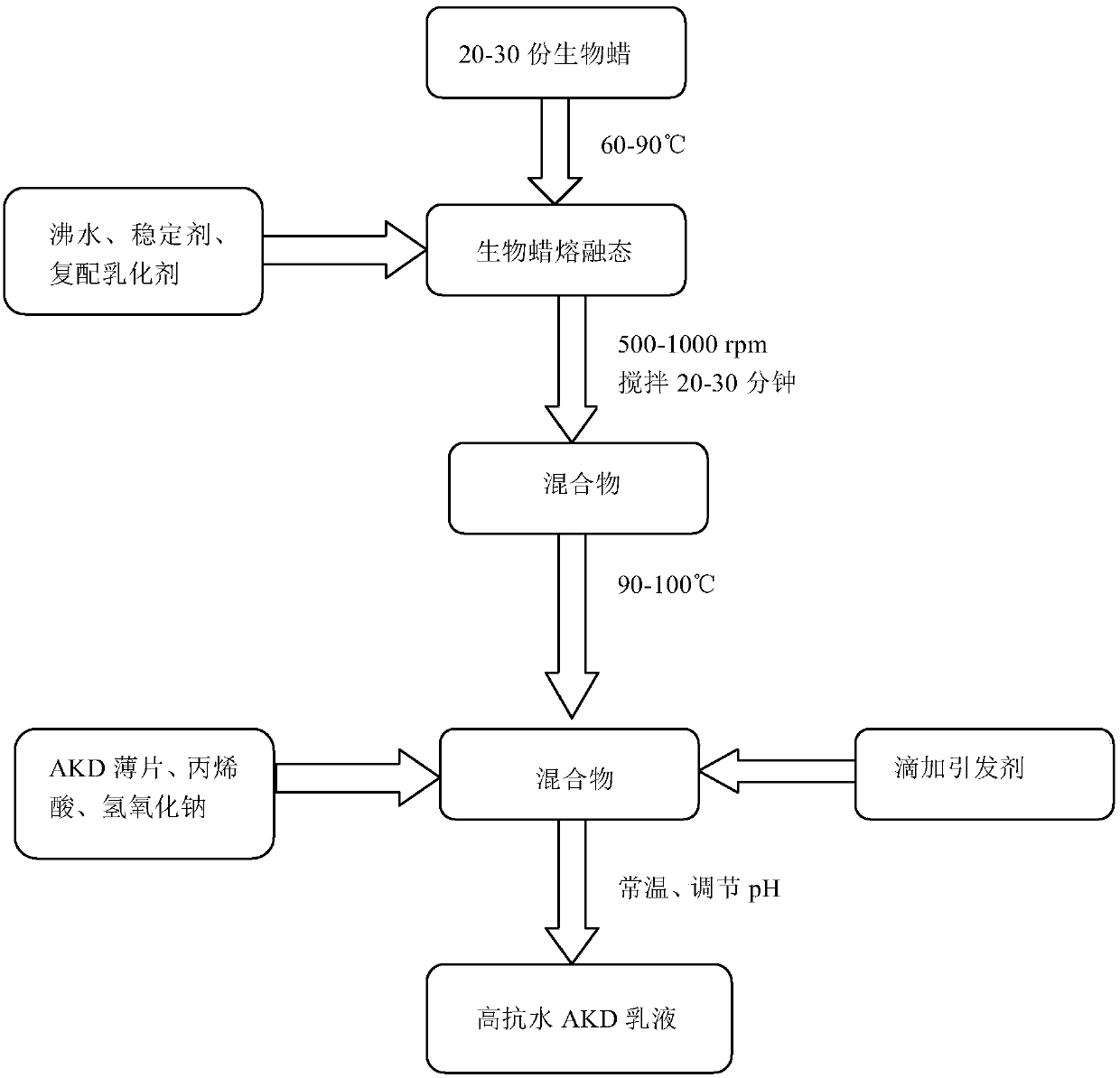

Method used

Image

Examples

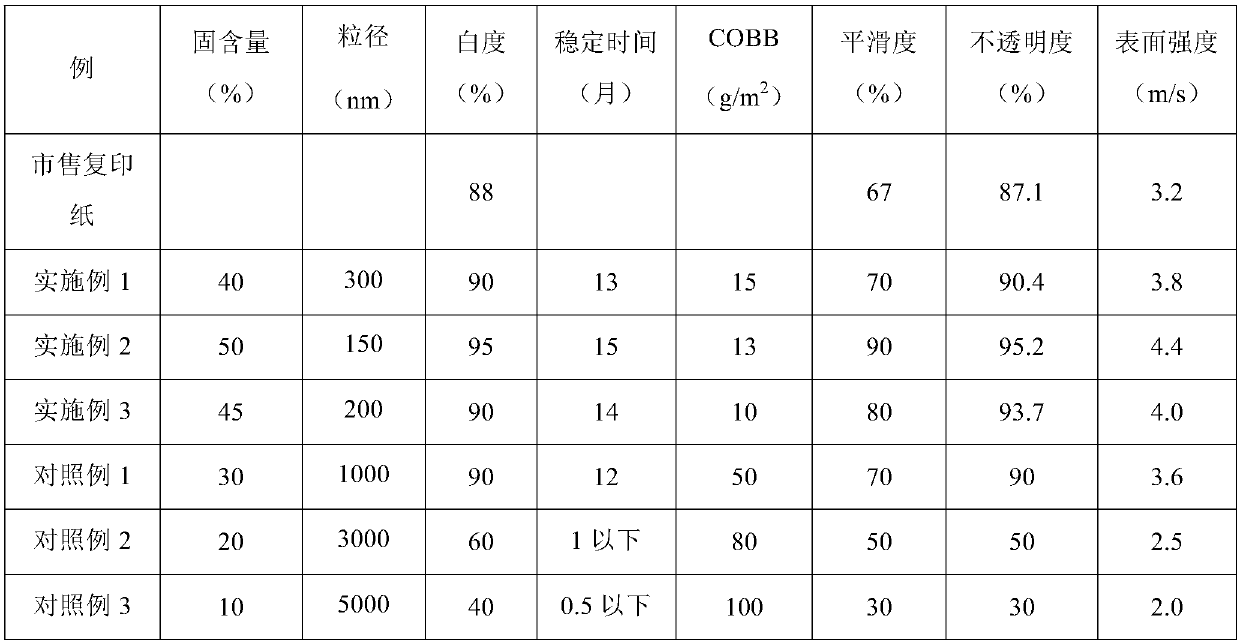

Embodiment 1

[0035] (1) Add 20 parts of palm wax into the reaction kettle, heat up to 60°C, after the palm wax melts, add 80 parts of boiling water, 1 part of corn starch, and 3 parts of compound emulsifier in a nitrogen protective atmosphere, 500rpm, Stir for 20 minutes;

[0036] (2) After the solution is completely mixed evenly, raise the temperature to 90°C, add 40 parts of AKD flakes, 5 parts of acrylic acid, 7 parts of sodium hydroxide, slowly add 3 parts of ammonium persulfate dropwise, 1000rpm, and stir for 5 hours;

[0037] (3) After the reaction is finished, the temperature is lowered to normal temperature, and the pH of the solution is adjusted with dilute hydrochloric acid, so that the emulsion is neutral, that is, the highly water-resistant AKD emulsion can be obtained.

[0038] The preparation method of the described compound emulsifier is: add 1 part of soybean lecithin, 2 parts of sucrose ester to 5 parts of water, add 0.1 part of guar gum, 0.2 part of water-soluble amino ac...

Embodiment 2

[0040] (1) Add 30 parts of peak wax into the reaction kettle, heat up to 90°C, after the beeswax melts, add 100 parts of boiling water, 3 parts of potato starch, 5 parts of compound emulsifier, 1000rpm, stir 30 minutes;

[0041] (2) After the solution is completely mixed evenly, raise the temperature to 100°C, add 50 parts of AKD flakes, 10 parts of acrylic acid, 9 parts of sodium hydroxide, slowly add 5 parts of potassium persulfate dropwise, 1500rpm, and stir for 10 hours;

[0042] (3) After the reaction is finished, the temperature is lowered to normal temperature, and the pH of the solution is adjusted with acetic acid to make the emulsion neutral, and the high water-resistant AKD emulsion can be obtained.

[0043] The preparation method of described compound emulsifier is: add 3 parts of soybean lecithin, 4 parts of sucrose ester to 10 parts of water, add 0.3 part of guar gum, 0.5 part of water-soluble amino acid, stir with homogenizer, 5000rpm, 8 minutes, A mixed emulsi...

Embodiment 3

[0045] (1) Add 25 parts of palm wax to the reaction kettle, heat up to 80°C, after the palm wax melts, add 90 parts of boiling water, 2 parts of sodium lignosulfonate, and 4 parts of compound emulsifier in a nitrogen protective atmosphere , 800rpm, stirring for 25 minutes;

[0046] (2) After the solution is completely mixed evenly, raise the temperature to 100°C, add 45 parts of AKD flakes, 7 parts of acrylic acid, and 8 parts of sodium hydroxide, slowly add 4 parts of tert-butyl peroxide dropwise, 1500 rpm, and stir for 7 hours;

[0047] (3) After the reaction is finished, the temperature is lowered to normal temperature, and the pH of the solution is adjusted with citric acid to make the emulsion neutral, and the high water-resistant AKD emulsion can be obtained.

[0048] The preparation method of the described compound emulsifier is: add 2 parts of soybean lecithin, 3 parts of sucrose ester to 8 parts of water, add 0.2 part of guar gum, 0.4 part of water-soluble amino acid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Cobb value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com