A detection method of workpiece residual stress

A residual stress and detection method technology, which is applied in the field of workpiece processing, can solve problems such as unqualified bonding of strain gauges and large fluctuations in detection results, and achieve the effects of avoiding too thick an adhesive layer, improving measurement accuracy, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

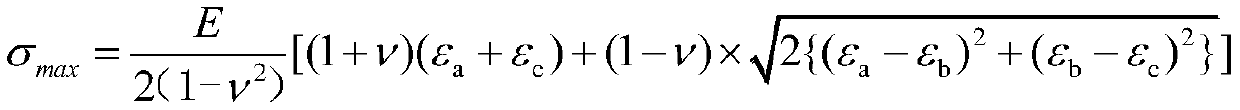

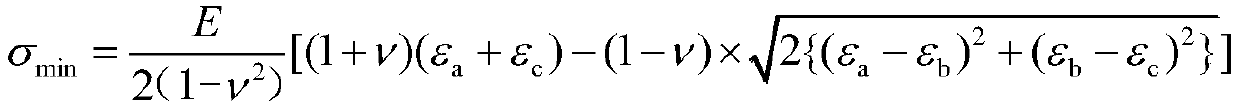

Method used

Image

Examples

Embodiment 1

[0043] To detect the residual stress of a heavy-duty diesel engine cylinder head casting blank, the steps are as follows:

[0044] Step 1: Combining the CAE stress simulation analysis results of the cylinder head and the area with high stress when the cylinder head is in use, determine the location to be inspected, inspection point A, inspection point B, and inspection point C;

[0045] Step 2: Grinding the surface of the castings at detection point A, detection point B, and detection point C, first use mechanical grinding for pre-grinding, pay attention to the surface temperature during the pre-grinding process, and cool down when the temperature rises, and pre-grind until the surface is oxidized After the skin is completely polished off, gradually use 80#, 120#, 240# sandpaper to fine-grind the surface of the detection position, and grind back and forth along the same direction as much as possible to ensure that the surface of the detection position is smooth and clean, witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com