Steel plate with yield strength at 460 MPa grade and preparation method thereof

A technology with a yield strength of 460mpa, applied in the field of steel plates with a yield strength of 460MPa and its preparation, can solve the problems of high precious metal content and high production cost of steel plates, and achieve the effects of simple preparation process, guaranteed welding performance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The purpose of the present invention is to provide a high-performance bridge steel plate with yield strength greater than 460MPa, low yield ratio, good corrosion resistance, low temperature toughness, cold forming performance and welding performance, which will be realized through the following specific implementation methods:

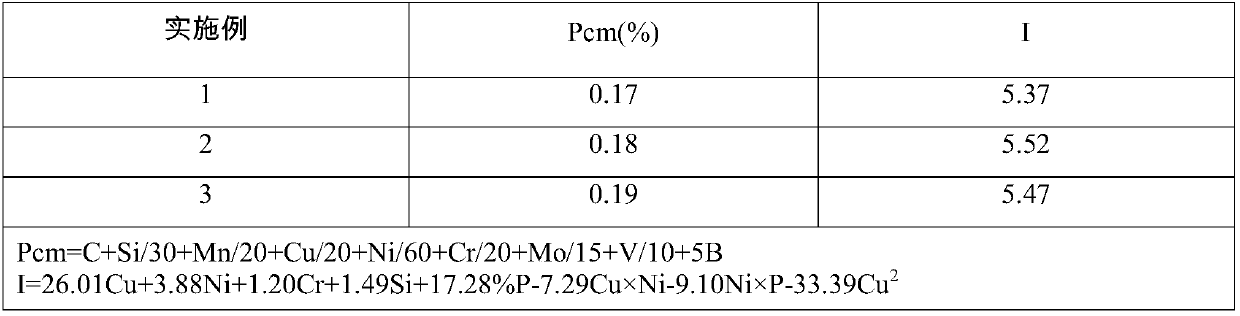

[0025] In the first embodiment of the present invention, the present invention provides a steel plate with a yield strength of 460 MPa. The composition of the steel plate is as follows: C: 0.06-0.08%, Si: 0.20-0.30%, Mn: 1.45 ~1.65%, P: ≤0.015%, S: ≤0.008%, Nb: 0.025~0.035%, Ti: 0.010-0.020%, Cu: 0.15~0.25%, Ni: 0.15-0.25%, Cr: 0.15-0.25% , Als: 0.024-0.034%, rare earth Ce: 0.0005-0.0030%, the balance is Fe and unavoidable impurities.

[0026] According to a preferred embodiment of the present invention, the composition of the above-mentioned steel plate is: C: 0.06-0.08%, Si: 0.20-0.27%, Mn: 1.49-1.55%, P: ≤0.013%, S: ≤ 0.003%, Nb: 0.028-0.034...

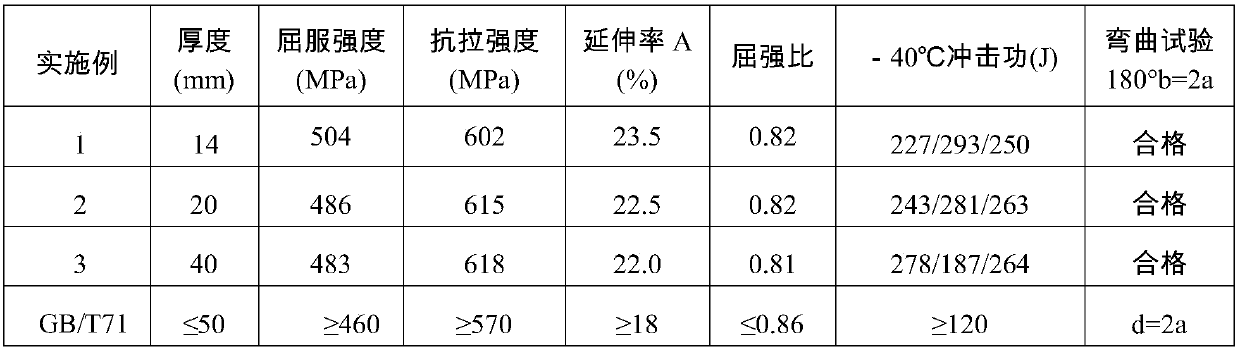

Embodiment 1

[0036] Smelt according to the chemical composition shown in Table 1, and cast into steel ingots, heat the steel ingots to 1210 ° C, and the total time in the furnace is 252 minutes, and carry out the first stage of rolling on the experimental rolling mill, that is, rolling in the austenite recrystallization zone. The rolling start temperature is 1176°C, the reduction in the first to second passes should be greater than 10%, and the reduction rate in at least 1 to 2 passes should be controlled above 25%. Temperature to 930 ° C, followed by the second stage of rolling, that is, rolling in the austenite non-recrystallized zone. The final rolling temperature is 830°C, and the thickness of the finished steel plate is 14mm. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 582°C at a rate of 12°C / s, and finally the steel plate can be obtained.

Embodiment 2

[0038] The implementation is the same as in Example 1, wherein the heating temperature is 1220°C, the total time in the furnace is 256 minutes, the rolling start temperature of the first stage rolling is 1175°C, the thickness of the intermediate billet is 60mm, and the rolling start temperature of the second stage rolling is The temperature is 925°C, the final rolling temperature is 836°C, and the thickness of the finished steel plate is 20mm. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 576°C at a rate of 13°C / s, and finally the steel plate can be obtained. Such as figure 1 As shown, the metallographic structure of the steel plate obtained in this embodiment is shown, and it can be clearly seen from the figure that the metallographic structure of the steel plate obtained by the present invention is mainly ferrite and bainite, and the grains are dense and fine chemical, so that the steel plate prepared by the present invention has str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com