Bulletproof polyurethane-fiber composite material and preparation method thereof

A fiber composite material and polyurethane composite material technology, applied in the field of composite materials, can solve the problems of poor bulletproof effect and low density of bulletproof inserts, achieve good safety protection and wearing experience, and enhance the ability to resist instantaneous deformation and flexibility. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

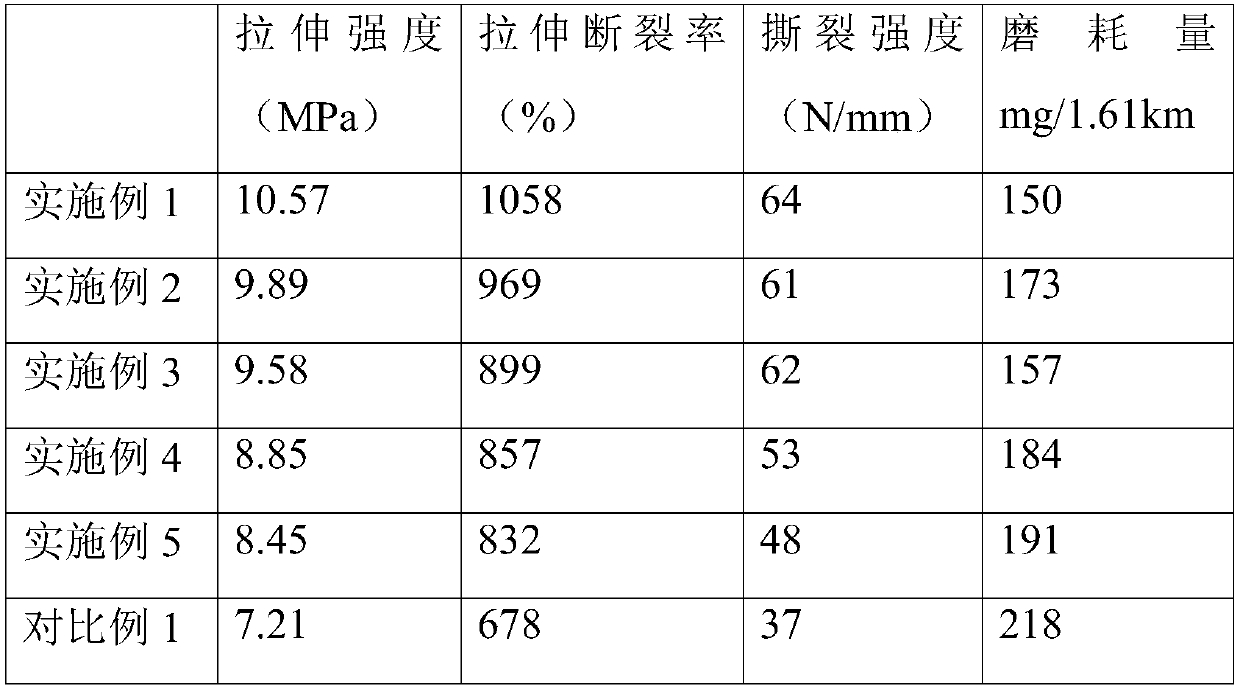

Examples

preparation example Construction

[0053] In a second aspect, the present invention provides a method for preparing a bulletproof polyurethane-fiber composite material, comprising the following steps:

[0054] (1) Weigh 40wt.%-60wt.% isocyanate and 40wt.%-60wt.% polymer polyol, heat the polymer polyol to 100-120°C, vacuum dehydrate for 1-2h, fill After entering nitrogen, cool to room temperature, add the isocyanate, heat to 60-90°C, keep warm and stir, react for 2-5h, lower the temperature to 40-50°C, discharge and package to obtain component A;

[0055] (2) Put the chain extender, dispersant, airgel, filler and catalyst into the container, disperse with a high-speed disperser for 15-60min, and pack it out to obtain component B. The mass percentage of the above components is:

[0056]

[0057] (3) Mix the A component and the B component uniformly to obtain a polyurethane composite;

[0058] (4) Clamp the mold after placing the fiber in the cavity of the mold, pump out the air in the cavity of the mold, inje...

Embodiment 1

[0067] (1) Put 50 parts by mass of polyether polyol in a container and heat it to 110°C, vacuumize and dehydrate for 1.5h, fill it with nitrogen and cool to room temperature, add 50 parts by mass of polymethylene polyphenyl polyisocyanate, Heat to 80°C, keep warm and stir, react for 4 hours, lower the temperature to 40°C, discharge and package to obtain component A.

[0068] (2) 27.5 parts by mass of 1,2-propanediol, 32 parts by mass of aerogel, 0.5 parts by mass of ethylene bisstearamide, 25 parts by mass of chopped glass fiber and 0.5 parts by mass of dibutyltin Add the lauric acid esters into the container respectively, disperse for 40 minutes with a high-speed disperser, and pack the material out to obtain component B.

[0069] (3) After mixing components A and B uniformly at a volume ratio of 5:1, a rapid prototyping high-strength flame-retardant polyurethane composite material was prepared.

[0070] (4) Close the mold after laying 3 layers of fiber in the cavity of the ...

Embodiment 2

[0072] (1) Put 50 parts by mass of polyester diol in a container and heat to 110°C, vacuum dehydrate for 1.5h, fill with nitrogen and cool to room temperature, add 20 parts by mass of diphenylmethane diisocyanate and 30 parts by mass One part of 1,6-hexamethylene diisocyanate was heated to 70°C, kept warm and stirred, reacted for 3.5 hours, the temperature was lowered to 45°C, and the material was packaged to obtain component A.

[0073] (2) 27 parts by mass of 1,4-butanediol, 43 parts by mass of airgel, 0.2 parts by mass of monoglyceride stearate, 10 parts by mass of chopped carbon fiber alumina powder, 12 parts by mass of Calcium carbonate powder, 0.2 parts by mass of bismuth neodecanoate and 0.2 parts by mass of stannous octoate were added to the container, dispersed with a high-speed disperser for 30 minutes, and packaged to obtain component B.

[0074] (3) After mixing components A and B uniformly at a volume ratio of 3:1, a rapid prototyping high-strength flame-retardant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com