Method for producing high foaming EPE pearl wool by using carbon dioxide foaming agent

A carbon dioxide and blowing agent technology, applied in the field of polymer material processing, can solve the problems of low structural strength, poor flame retardancy, flammability and explosion, etc., and achieve the effect of good flame retardancy, low cost and high bubble density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

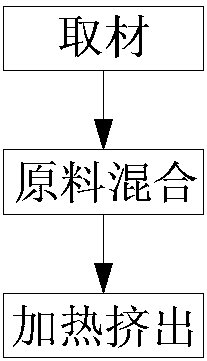

[0018] The method for producing high-foaming EPE pearl cotton by adopting carbon dioxide blowing agent comprises the steps:

[0019] S1: Materials: expandable polyethylene: 70 parts, carbon dioxide foaming agent: 4 parts, anti-shrinkage agent: 3 parts, monoglyceride: 0.8 parts, talcum powder: 1 part, silica airgel: 6 parts Parts, composite blowing agent: 4 parts and filler: 20 parts, composite blowing agent includes azodicarbonamide, zinc oxide and silicon dioxide, the component ratio between azodicarbonamide, zinc oxide and silicon dioxide It is 10:1:2, and the filler includes bentonite, clay, asbestos fiber and light calcium carbonate;

[0020] S2: Mixing of raw materials: Put the expandable polyethylene in a mixer and knead for 5 minutes, then add talcum powder, silica airgel and fillers and continue kneading for 18 minutes to obtain a mixture, and the kneading temperature is 60 degrees Celsius ;

[0021] S3: Heat extrusion: Pour the mixture obtained in step S2 into a hig...

Embodiment 2

[0023] The method for producing high-foaming EPE pearl cotton by adopting carbon dioxide blowing agent comprises the steps:

[0024] S1: Materials: expandable polyethylene: 80 parts, carbon dioxide foaming agent: 2 parts, anti-shrinkage agent: 5 parts, monoglyceride: 0.6 parts, talcum powder: 2 parts, silica airgel: 4 parts Parts, composite blowing agent: 10 parts and filler: 15 parts, composite blowing agent includes azodicarbonamide, zinc oxide and silicon dioxide, the component ratio between azodicarbonamide, zinc oxide and silicon dioxide It is 10:1:2, and the filler includes bentonite, clay, asbestos fiber and light calcium carbonate;

[0025] S2: Mixing of raw materials: put the expandable polyethylene in a mixer and knead for 3 minutes, then add talcum powder, silica airgel and fillers and continue kneading for 16 minutes to obtain a mixture, the kneading temperature is 50 degrees Celsius ;

[0026] S3: Heat extrusion: Pour the mixture obtained in step S2 into a high-...

Embodiment 3

[0028] The method for producing high-foaming EPE pearl cotton by adopting carbon dioxide blowing agent comprises the steps:

[0029] S1: Materials: expandable polyethylene: 75 parts, carbon dioxide foaming agent: 3 parts, anti-shrinkage agent: 4 parts, monoglyceride: 0.7 parts, talcum powder: 2 parts, silica airgel: 5 parts Parts, composite blowing agent: 7 parts and filler: 17 parts, composite blowing agent includes azodicarbonamide, zinc oxide and silicon dioxide, the component ratio between azodicarbonamide, zinc oxide and silicon dioxide It is 10:1:2, and the filler includes bentonite, clay, asbestos fiber and light calcium carbonate;

[0030] S2: Mixing of raw materials: put the expandable polyethylene in the mixer and knead for 4 minutes, then add talcum powder, silica airgel and fillers and continue kneading for 17 minutes to obtain a mixture, the kneading temperature is 55 degrees Celsius ;

[0031] S3: Heat extrusion: Pour the mixture obtained in step S2 into a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com