Nano-scale controllable porous polymer film and preparation method thereof

A porous polymer, nano-sized technology, applied in the field of porous film materials, can solve the problems of difficult control of parameters, large-scale instruments and equipment, and complex process of nano-sized uniform porous film, so as to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

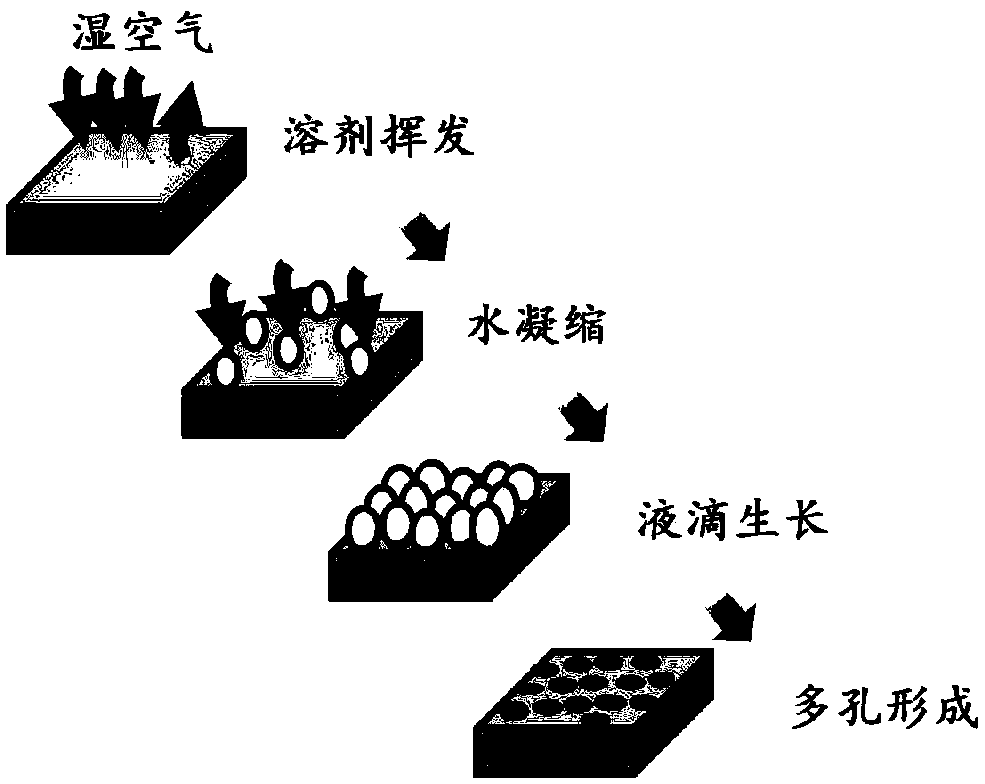

[0027] The invention provides a method for preparing a porous polymer film with controllable nanometer size, comprising the following steps:

[0028] dissolving the polymer in an organic solvent to obtain a polymer solution;

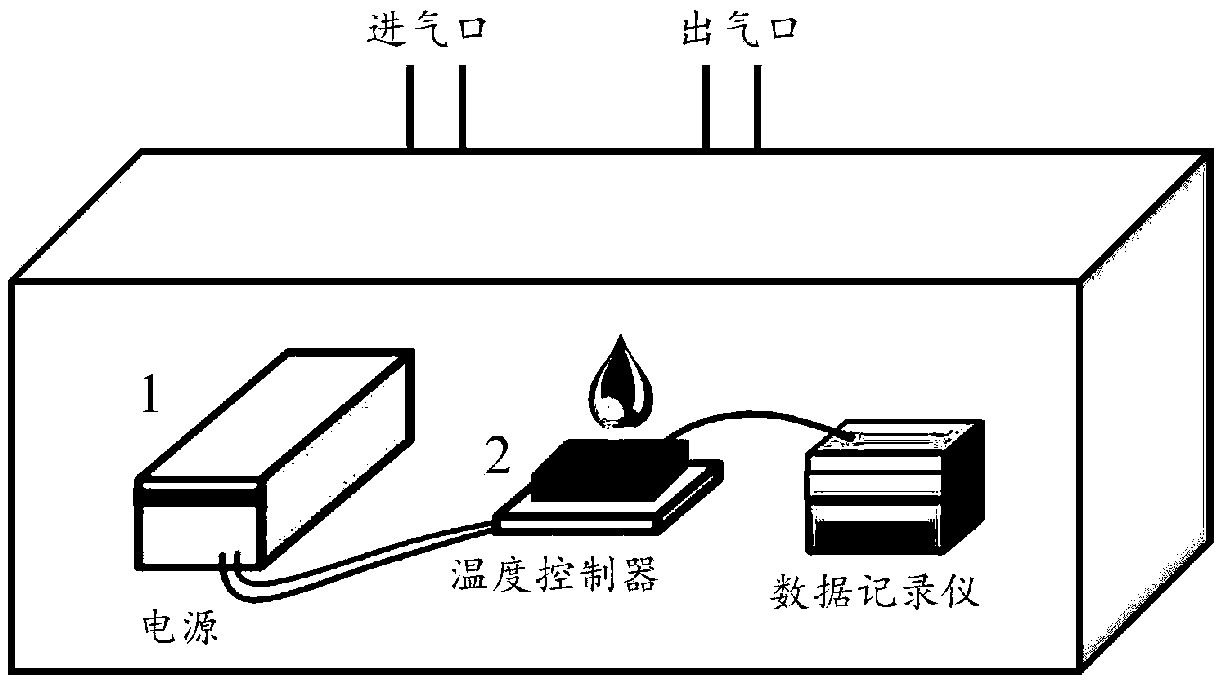

[0029] drip-coating the polymer solution onto a glass substrate in an environment with a relative humidity of 45% to 90%, to obtain a polymer liquid film;

[0030] Adjusting the temperature of the glass substrate and keeping the temperature constant for 20 to 60 seconds, a porous polymer film with controllable nanometer size is obtained,

[0031] The temperature range of the glass substrate is adjusted to be 3° C. to 28° C.

[0032] In the invention, the polymer is dissolved in an organic solvent to obtain a polymer solution. In the present invention, the mass ratio of the polymer to the organic solvent is preferably 0.01˜0.04:1, more preferably 0.01:1. In the present invention, the organic solvent preferably includes one or more of chloroform, dichlo...

Embodiment 1

[0047] Polystyrene (Mn=208,000 g / mol) with a mass ratio of 0.01:1 was dissolved in chloroform solvent to obtain a polystyrene solution. At 13°C, adjust the relative humidity in the airtight box to 85%, and keep the humidity constant.

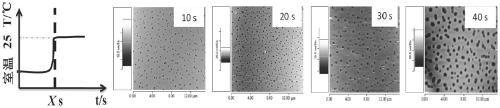

[0048] Drop-coat 40 μL of polystyrene solution onto a clean glass slide and let it stand at room temperature (13°C) for 10s, 20s, 30s, and 40s respectively, then immediately increase the current of the constant current power supply at a heating rate of 5°C / s The temperature of the glass substrate was raised to 25°C, and the temperature was kept constant for 60s until the film was dried to obtain porous polystyrene films with different nanopore diameters.

[0049] image 3 For the porous polystyrene film AFM figure that embodiment 1 prepares, from image 3 It can be seen that the average pore diameters of the porous polystyrene films prepared after standing at 13°C for 10s, 20s, 30s, and 40s are 100nm, 120nm, 200nm, and 320nm, and the average p...

Embodiment 2

[0051] Polystyrene (Mn=208,000 g / mol) with a mass ratio of 0.01:1 was dissolved in chloroform solvent to obtain a polystyrene solution. At 13°C, adjust the relative humidity in the airtight box to 85%, and keep the humidity constant.

[0052] 40 μL of polystyrene solution was drop-coated onto a clean glass slide, and porous polystyrene films with different pore sizes were obtained through four different substrate temperature control processes. The specific process was as follows:

[0053] For process A, the temperature of the glass substrate is maintained at 13°C for 20s, and the temperature of the glass substrate is raised to 25°C at a heating rate of 5°C / s, and kept at a constant temperature for 40s to obtain an average pore diameter of 120nm and an average pore depth of 27nm. Dense porous polystyrene film with 60% porosity.

[0054] For process B, lower the temperature of the glass substrate from 13°C to 7°C and keep the temperature constant for 20s, raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com