An automatic shoe sole grinding machine

A grinding machine and shoe sole technology, which is applied to the grinding machine frame, the parts of the grinding machine tool, and the machine tool suitable for grinding the plane of the workpiece, etc. It can solve the problems of manual grinding of shoe soles such as difficulty in controlling the quality and low work efficiency. Achieve high grinding efficiency and prevent shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

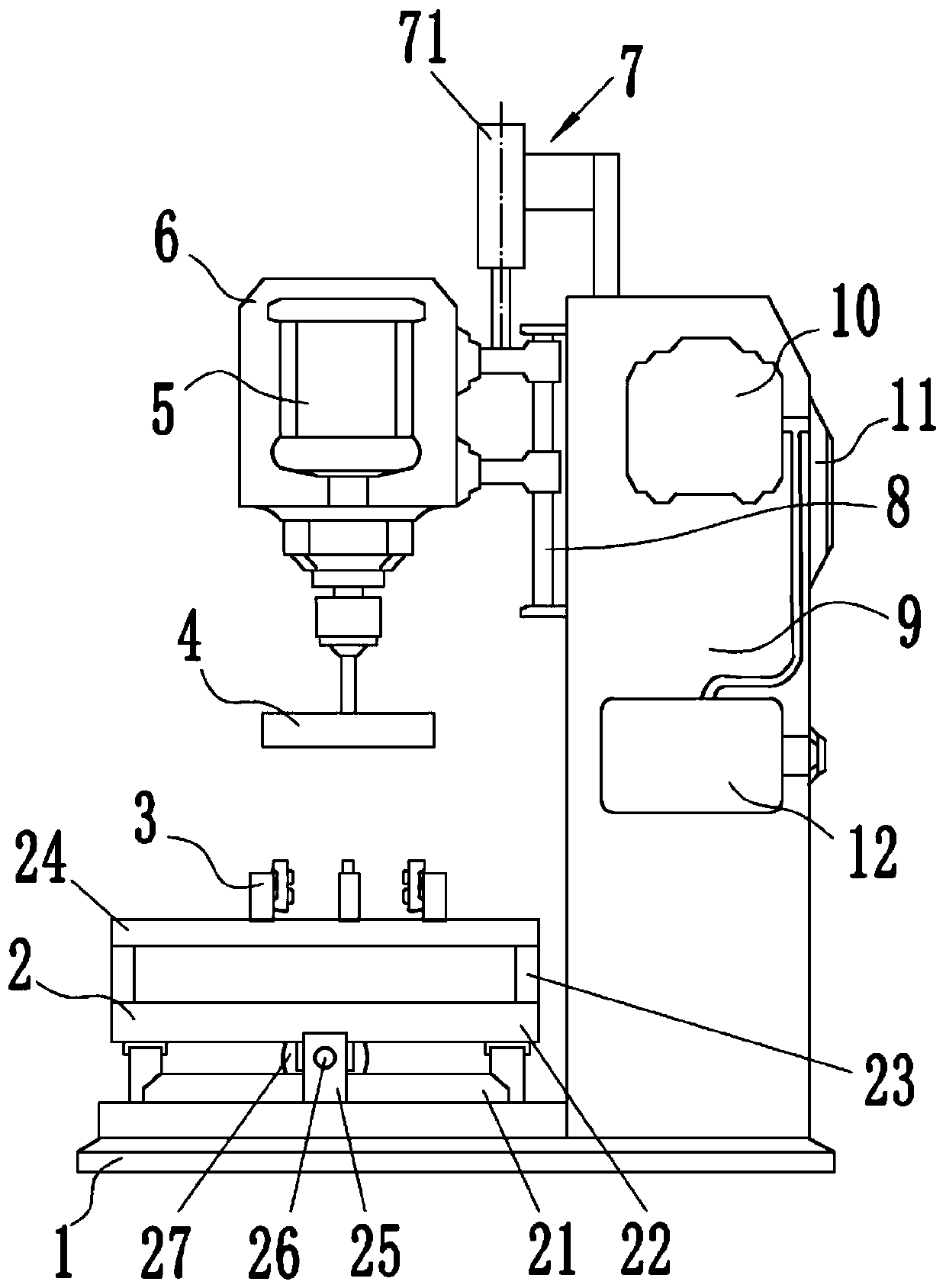

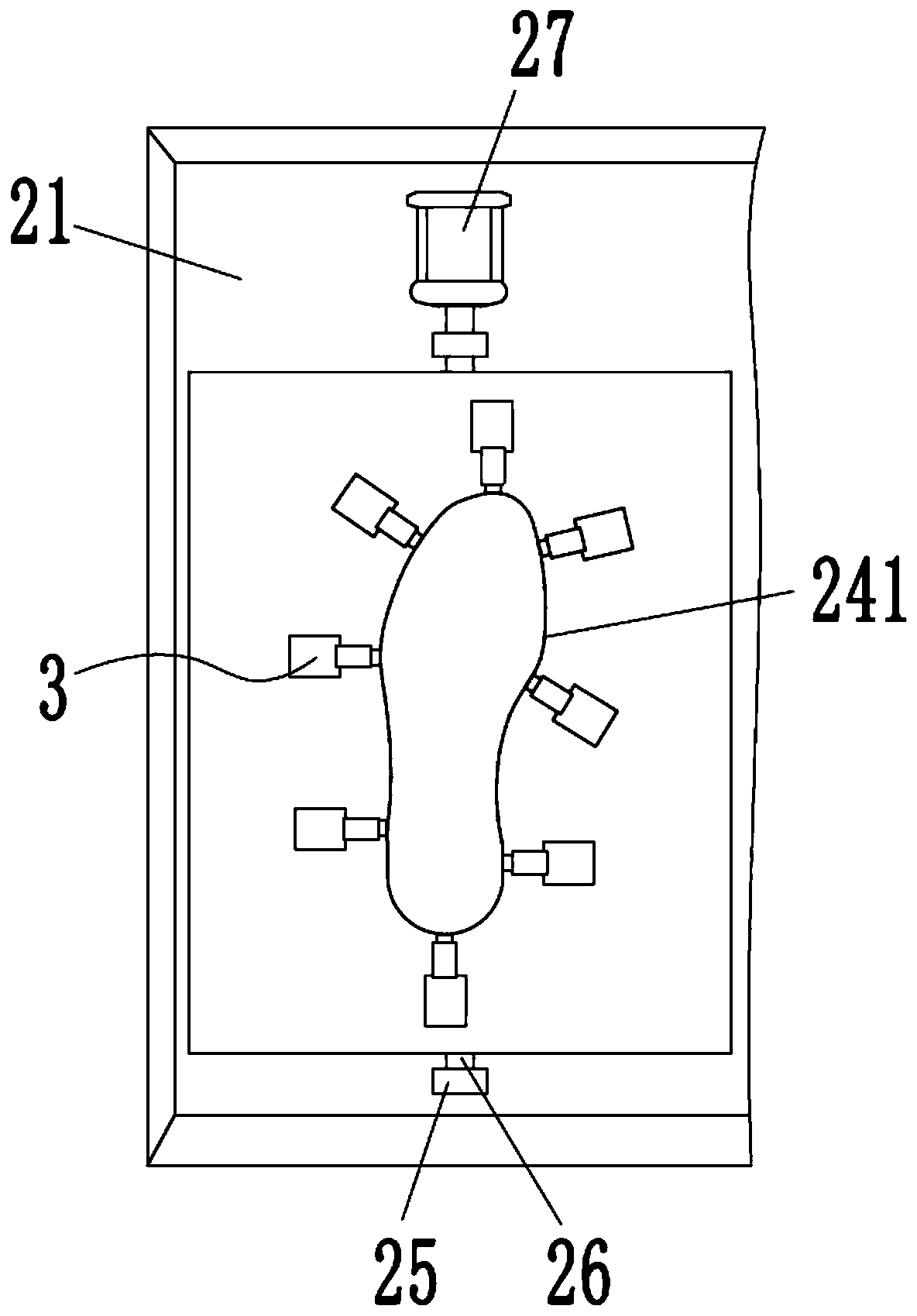

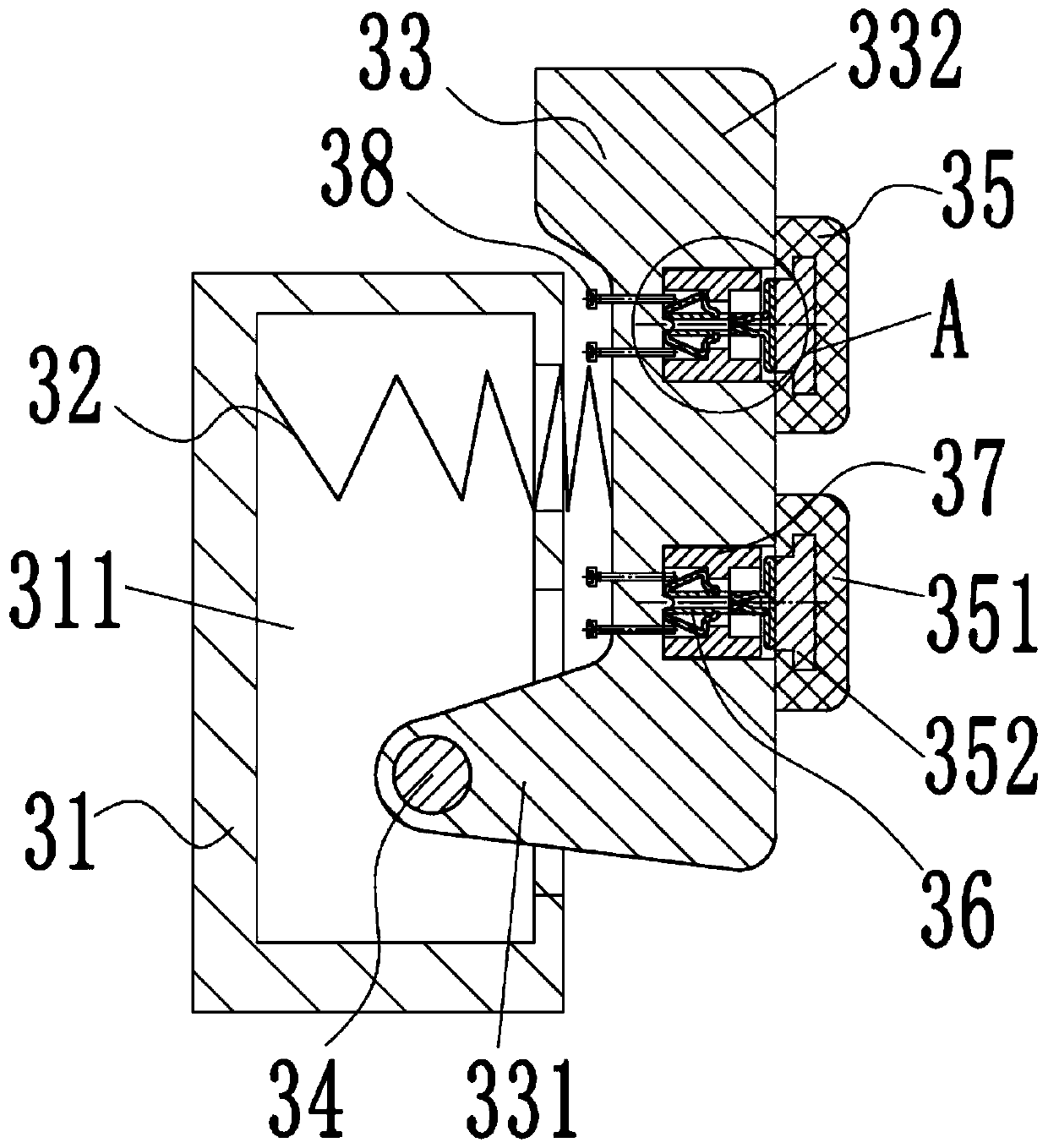

[0026] Refer below Figure 1 to Figure 6 The present invention is further described, as figure 1 The shown automatic shoe sole grinding machine includes: a base 1, a workbench 2, a cabinet 9, a motor frame 6, a transmission mechanism 7, several clamps 3, a processor 10, a control panel 11 and a circuit box 12, and the workbench 2 Movably arranged on the base 1, the cabinet 9 is vertically arranged at one end of the workbench 2, the motor frame 6 is movably arranged on one side of the cabinet 9, and the transmission mechanism 7 is used to drive the motor frame 6 along one side of the cabinet 9. Guide rail 8 moves up and down, and motor frame 6 is positioned at the top of workbench 2, and drive motor 5 is installed on the motor frame 6, and grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com