Mineral flotation collector as well as preparation method and application thereof

A mineral flotation and collector technology, applied in flotation, solid separation, etc., can solve the problems of scheelite, fine-grained cassiterite and wolframite with poor flotation effect, and achieve good selective collection capacity , enhanced selectivity, good collection and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

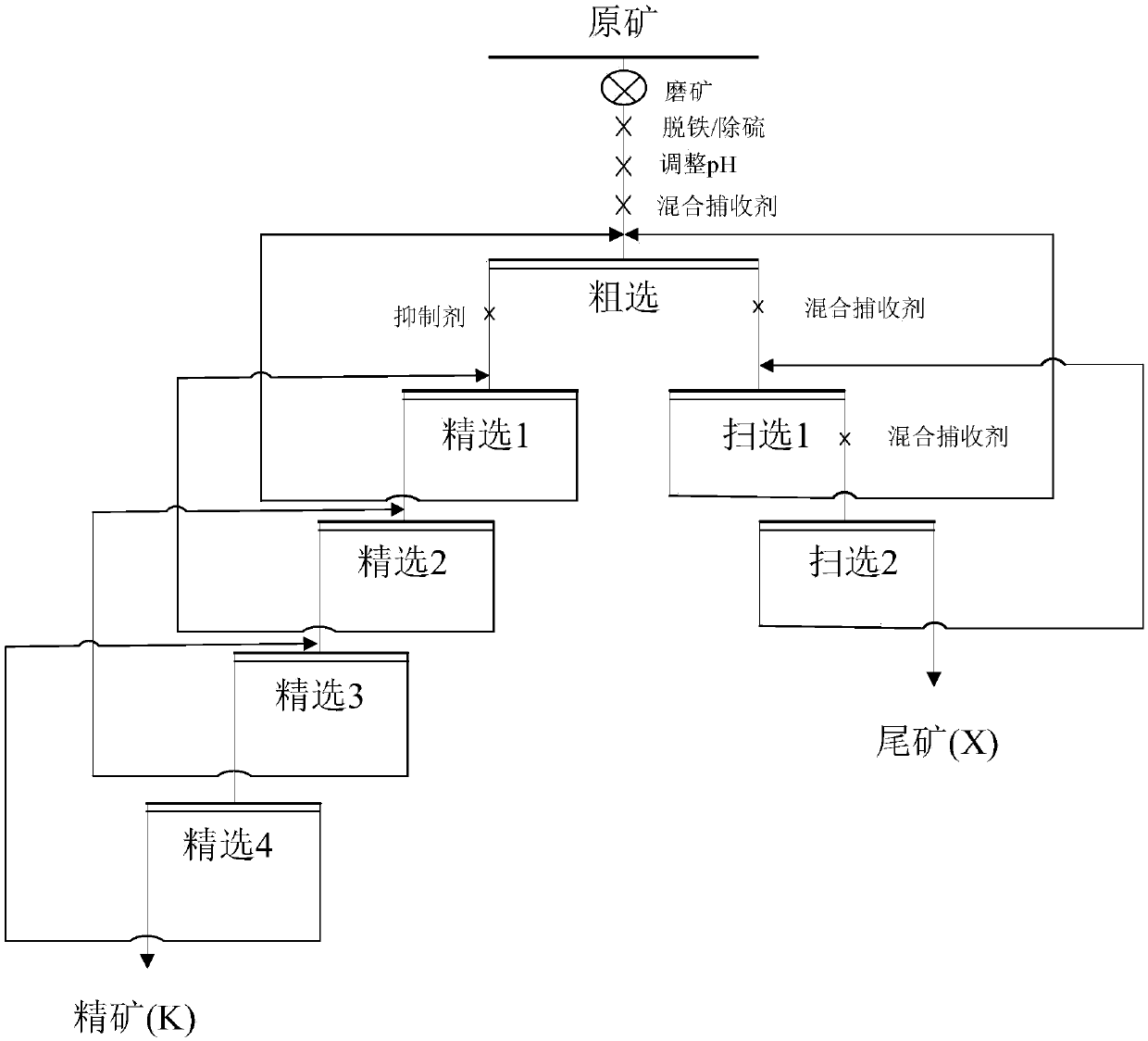

[0040] Utilize the mineral flotation collector of the present invention to process scheelite ore in a certain place in Henan, its technological process is as follows figure 1 Shown (the mixed collector in the figure is the mineral flotation collector of the present invention), wherein the tungsten grade WO 3 The gangue is mainly feldspar, diopside, quartz and a small amount of calcite, fluorite and square pillar.

[0041] Combine calcium chloride: salicylic hydroxamic acid: linoleic acid = 0.7:1.5:0.2 according to the mass ratio and put it into a 250mL three-neck flask, add water to form a solution with a mass fraction of 10%, then start the magnetic stirrer and stir The speed is 600r / min, the constant temperature of the water bath is 60°C, and the prepared mineral flotation collector is taken out after stirring for 20 minutes.

[0042] Grind the scheelite ore to -0.074mm, accounting for 70%-76% fineness, put it into the flotation tank and stir for 1min, adjust the pH of the ...

Embodiment 2

[0047] Utilize the mineral flotation collector of the present invention to process tungsten-tin raw ore in a certain place in Hunan, and its technological process is as follows figure 1 Shown, where tungsten grade WO 3 0.40% (70% of scheelite and 30% wolframite), Sn grade of 0.17%, gangue mainly garnet, fluorite, quartz, mica, calcite and a small amount of montmorillonite and chlorite Wait.

[0048] According to the mass ratio, lead nitrate: benzohydroxamic acid: oxidized paraffin wax soap = 1:1:0.1 is combined and put into a 250mL three-necked flask, water is added to form a solution with a mass fraction of 7%, and then the magnetic stirrer is started. The stirring speed is 700r / min, the constant temperature of the water bath is 70°C, and the prepared mineral flotation collector is taken out after stirring for 15 minutes.

[0049] Grind the raw tungsten-tin ore to -0.074mm, accounting for 75%-80% fineness, put it into the flotation tank and stir for 1min, adjust the pH of t...

Embodiment 3

[0054] Utilize the mineral flotation collector of the present invention to process tin ore in a certain place in Guangxi, its technological process is as follows figure 1 As shown, the tin grade Sn in the tailings after sulfur selection is 0.52%, and the gangue is mainly quartz, calcite, and a small amount of mica and dolomite.

[0055] Combining manganese sulfate: N-oleoyl sarcosine: sodium dodecylsulfonate = 0.5:1.5:0.5 according to the mass ratio, put it into a 250mL three-necked flask, add water to form a solution with a mass fraction of 15%, Then start the magnetic stirrer, the stirring speed is 500r / min, the constant temperature of the water bath is 60°C, and take out the prepared mineral flotation collector after stirring for 25min.

[0056] Grind the tin ore to a fineness of -0.074mm, accounting for 70%-75%, put it into the flotation tank and stir for 1min, adjust the pH of the slurry to 9.0-9.5, and then add 300g of the prepared mineral floatation to each ton of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com