Ultrasound-assisted method for thawing mango pulp with still water

An ultrasonic-assisted, mango pulp technology is applied in the fields of fruit and vegetable preservation, food preservation, and food science. It can solve the problems of expensive high-pressure thawing equipment, overheating, and accelerated product quality changes, and achieve shortened thawing time, reduced thawing time, and equipment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

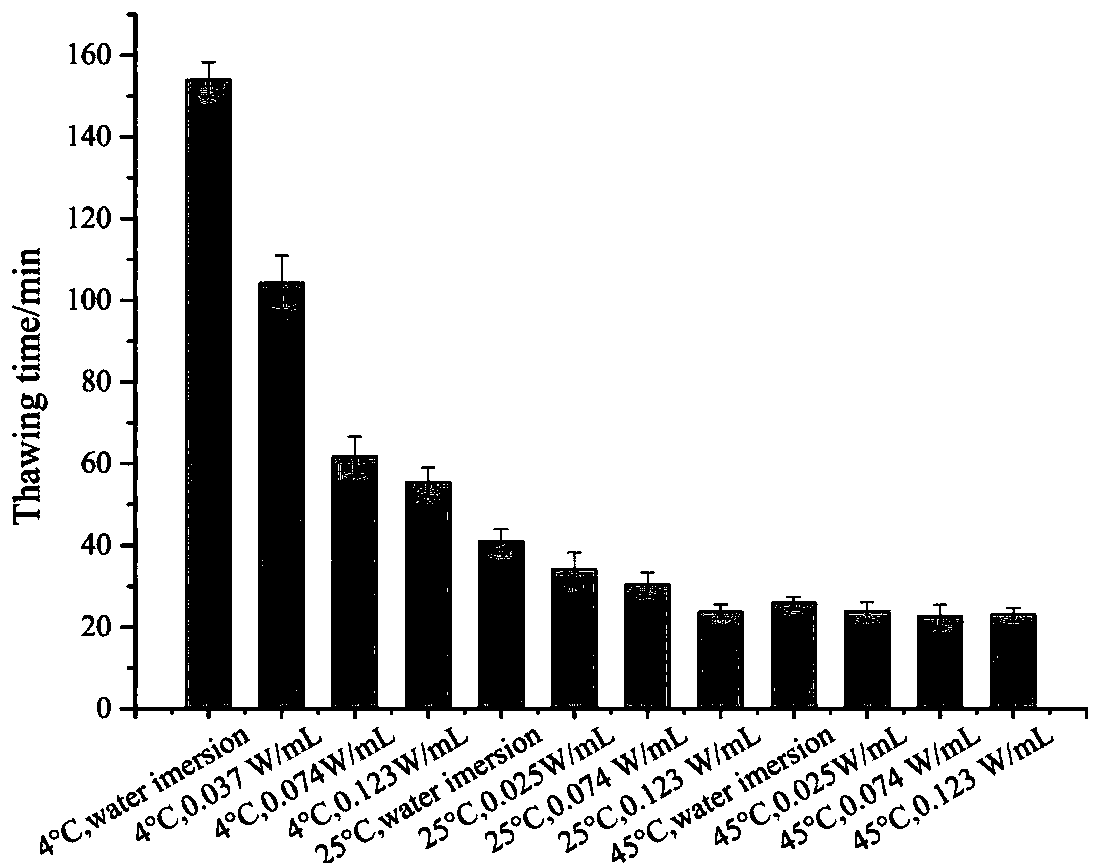

[0009] Experiment 1: Thawing time

[0010] During the thawing process, the temperature of the geometric center of the sample is recorded every 30 seconds by the wireless temperature detector until the temperature reaches 0°C, the sample is considered to be completely melted, and the temperature at the central point of the sample rises from -18°C to 0°C as the thawing time. The effect of different ultrasonic temperature and power on the thawing time is shown in figure 1 .

[0011] The results showed that the ultrasonic thawing time was shortened by 51-73% at 25°C compared with 4°C; when the temperature rose to 45°C, the ultrasonic thawing time was reduced by 2.9-30.0% compared with 25°C. Therefore, considering economy and efficiency, it is more appropriate to choose 25°C.

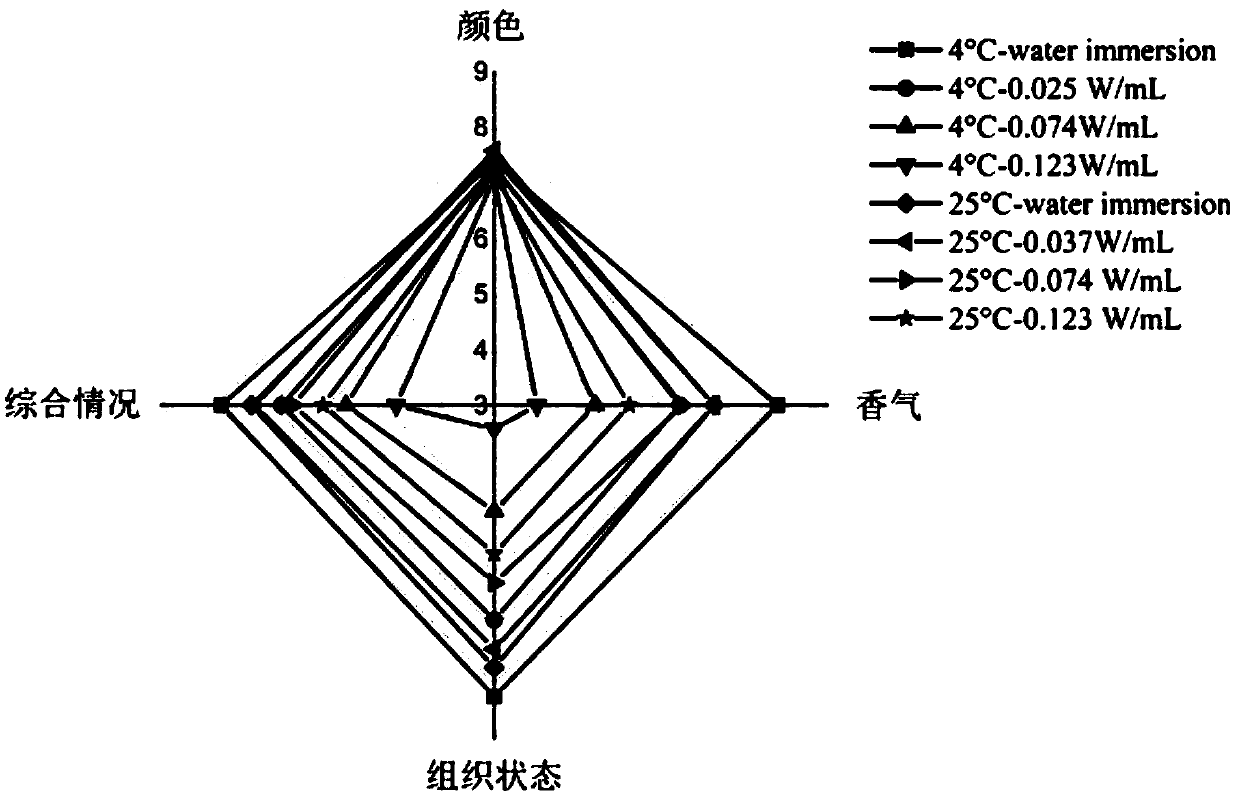

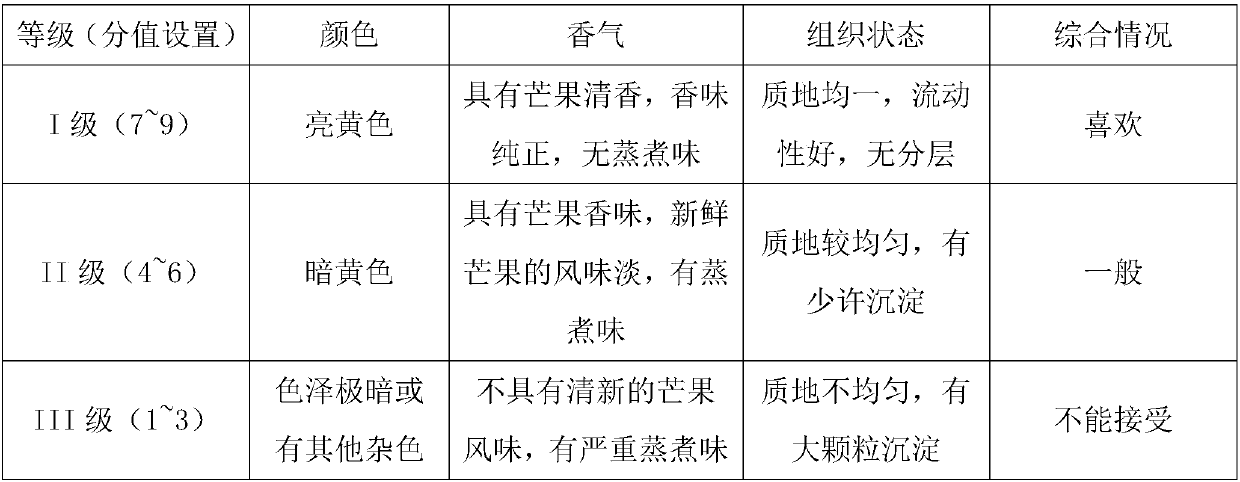

[0012] Experiment 2: Sensory Evaluation

[0013] Eight samples thawed at 4, 25°C, 0, 0.025, 0.074, 0.123W / mL were given to the sensory evaluation team members for evaluation. The color, smell, texture a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com