Frozen meat product thawing method and device

A technology for meat and products, which is applied in the direction of preserving meat/fish through freezing/cooling, which can solve the problems of long thawing time and decline in meat quality, and achieve the effects of ensuring food safety, avoiding food hygiene problems, and shortening thawing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

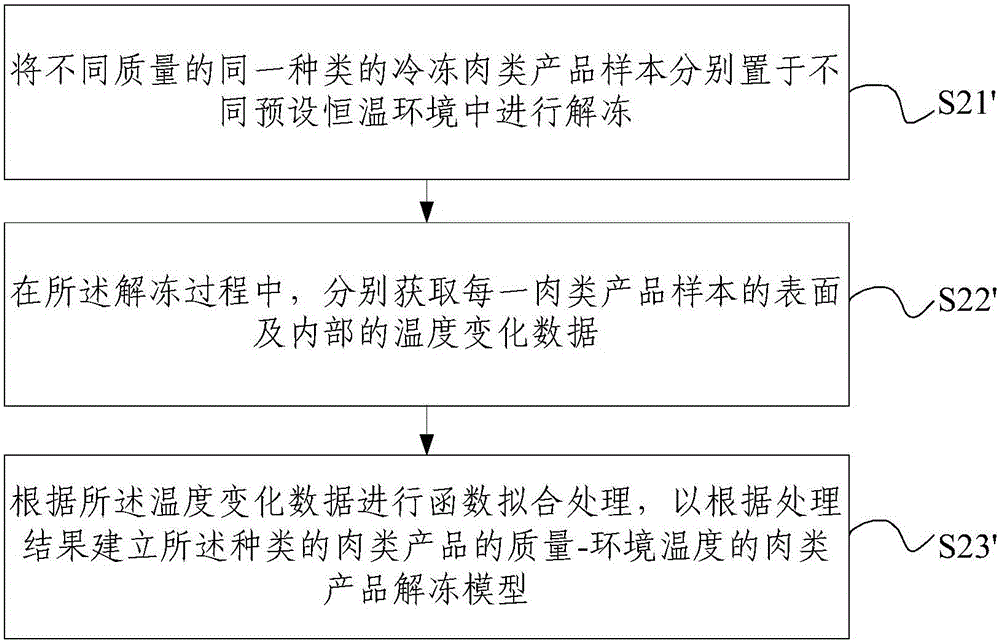

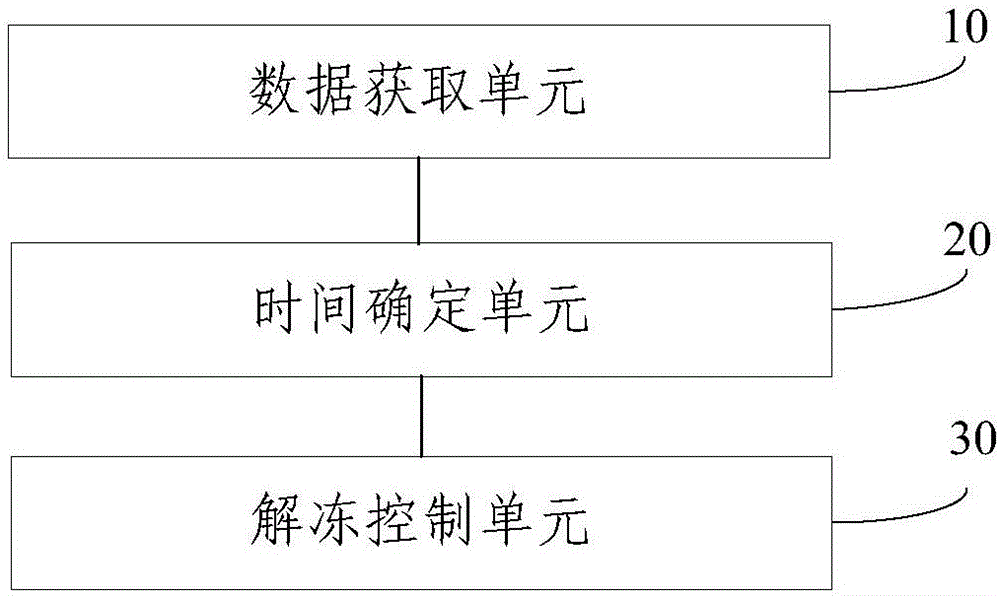

Method used

Image

Examples

Embodiment 1

[0121] The specific steps of the two-stage thawing method for ultra-low temperature tuna include: .

[0122] B1: Quickly weigh the ultra-low temperature tuna to be thawed and put it into the thawing device.

[0123] B2: Enter the product quality as 0.50kg through the key input module, and set the ambient temperature in the high-temperature thawing stage as 10°C. The liquid crystal display shows that the thawing time in the high temperature stage is 1 hour and 55 minutes, and the high temperature thawing stage starts. The temperature monitoring module starts to keep the temperature stable.

[0124] B3: When the remaining time displayed on the LCD screen is 0, there will be a prompt sound. The temperature monitoring module controls the ambient temperature to drop to 4°C, and the liquid crystal display shows that the low-temperature thawing stage time is 14 hours and 30 minutes. The temperature control module monitors the ambient temperature, and if it exceeds the set range, t...

Embodiment 2

[0136] The specific steps of the two-stage thawing method for high-grade steaks include:

[0137] C1: Quickly weigh the high-grade steak to be thawed and put it into the thawing device.

[0138] C2: Enter the product quality as 0.25kg through the key input module, and set the ambient temperature in the high-temperature thawing stage to 20°C. The thawing time of the liquid crystal display output high temperature stage is 1 hour and 20 minutes, and the high temperature thawing stage starts. The temperature monitoring module starts to keep the temperature stable.

[0139] C3: When the remaining time displayed on the LCD screen is 0, there will be a prompt sound. The temperature monitoring module controls the ambient temperature to drop to 4°C, and the liquid crystal display shows that the low-temperature thawing stage time is 8 hours and 35 minutes. The temperature control module monitors the ambient temperature, and if it exceeds the set range, the sound and light alarm modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com