A silver-copper melt with a sandwich structure

A sandwich, silver-copper technology, applied in the direction of emergency protection devices, electrical components, circuits, etc., can solve the problem of increasing the cost of punching equipment feeding mechanism and punching mold production, not being able to realize circuit overload protection well, and the cost of electrical products Problems such as high and low, to achieve the effect of reducing product resistance, stable size, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

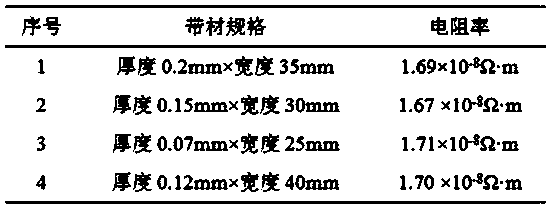

[0024] A silver-copper melt with a sandwich structure, the silver-copper melt comprising a copper core and silver layers arranged on both sides of the copper core, the silver-copper melt being strip-shaped, with a width of 35 mm and a thickness of 0.2 mm; The pure silver material in the outer layer has good electrical conductivity and undertakes the conductive function of the circuit. The copper material in the core part saves the amount of pure silver used and reduces the cost; secondly, the silver-copper melt of the present invention has a low melting point. Utilizing the metallurgical effect, the molten silver-copper alloy spreads and fuses the copper and silver on both sides in time, so that the melt fuses quickly and protects the circuit in time; and the processing performance is good, and the outer silver layer is evenly distributed, which is convenient for subsequent narrow neck processing and punching.

[0025] The preparation method of described silver-copper melt comp...

Embodiment 2

[0033] A silver-copper melt with a sandwich structure, the silver-copper melt comprising a copper core and silver layers arranged on both sides of the copper core, the silver-copper melt being strip-shaped, with a width of 30 mm and a thickness of 0.15 mm; The pure silver material in the outer layer has good electrical conductivity and undertakes the conductive function of the circuit. The copper material in the core part saves the amount of pure silver used and reduces the cost; secondly, the silver-copper melt of the present invention has a low melting point. Utilizing the metallurgical effect, the molten silver-copper alloy spreads and fuses the copper and silver on both sides in time, so that the melt fuses quickly and protects the circuit in time; and the processing performance is good, and the outer silver layer is evenly distributed, which is convenient for subsequent narrow neck processing and punching.

[0034] The preparation method of described silver-copper melt com...

Embodiment 3

[0042] A silver-copper melt with a sandwich structure, the silver-copper melt comprising a copper core and silver layers arranged on both sides of the copper core, the silver-copper melt being strip-shaped, with a width of 25mm and a thickness of 0.07mm; The pure silver material in the outer layer has good electrical conductivity and undertakes the conductive function of the circuit. The copper material in the core part saves the amount of pure silver used and reduces the cost; secondly, the silver-copper melt of the present invention has a low melting point. Utilizing the metallurgical effect, the molten silver-copper alloy spreads and fuses the copper and silver on both sides in time, so that the melt fuses quickly and protects the circuit in time; and the processing performance is good, and the outer silver layer is evenly distributed, which is convenient for subsequent narrow neck processing and punching.

[0043] The preparation method of described silver-copper melt compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com