Preparation method of I-131 standard powdered milk sample

A technology of I-131 and a.i-131, which is applied in the field of preparation of I-131 standard milk powder samples, can solve the problems affecting the efficiency and calibration accuracy of the instrument, poor stability of standard samples, and damage to the physical properties of milk powder, so as to achieve non-volatile and stable The effect of strong resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

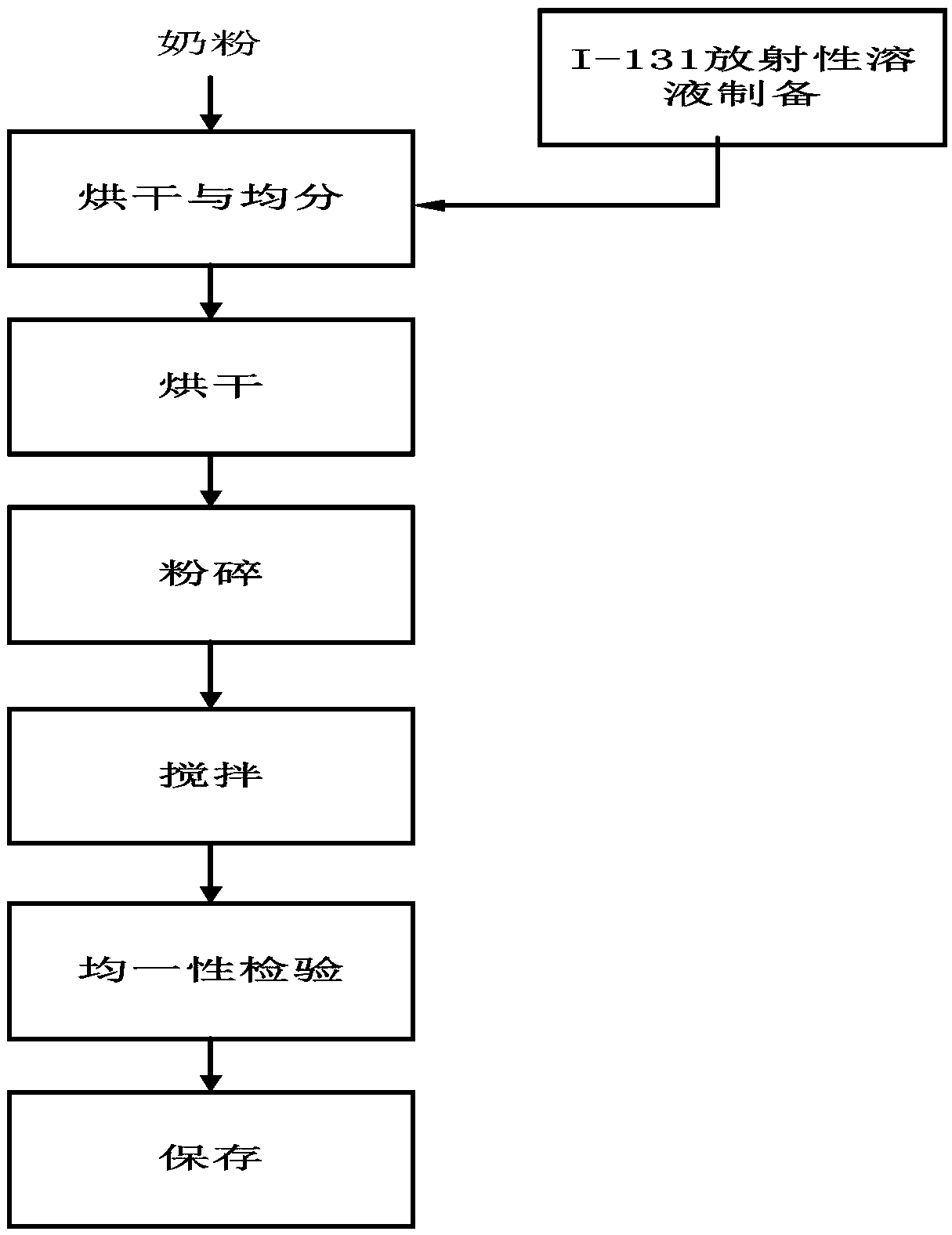

Image

Examples

Embodiment Construction

[0025] The following embodiments are provided in conjunction with the content of the present disclosure:

[0026] 1) Take 1ml 20000Bq I-131 standard solution into a 1L volumetric flask, and then use 2mol / L HNO 3 The solution is constant volume, and then transferred to a 3L beaker, and 1L 4mol / L AgNO is added under stirring conditions 3 Neutral solution, continue to stir, and drop 4mol / LKI solution until the precipitate is dissolved.

[0027] 2) 2kg milk powder is dried in an oven at 60℃ to a constant weight, and then the milk powder is divided into 20 parts, respectively, in a cylindrical sample box with a diameter of 3cm and a height of 5cm;

[0028] 3) Take 20 parts from the I-131 solution prepared in step 1), each 20 ml, and add them to the evenly divided samples in step 2);

[0029] 4) Pour the powdered milk with I-131 solution added in step 3) into an enamel dish, spread it out, and then dry it in an oven at 60°C;

[0030] 5) After drying, the sample is pulverized on a crusher;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com