Two-step preparation method for Zr, Ti, Al multivariate modified silicide seepage layer

A silicide, step-by-step technology, applied in the field of multi-component modified silicide infiltration layer, to achieve excellent high temperature oxidation resistance, easy infiltration layer optimization, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

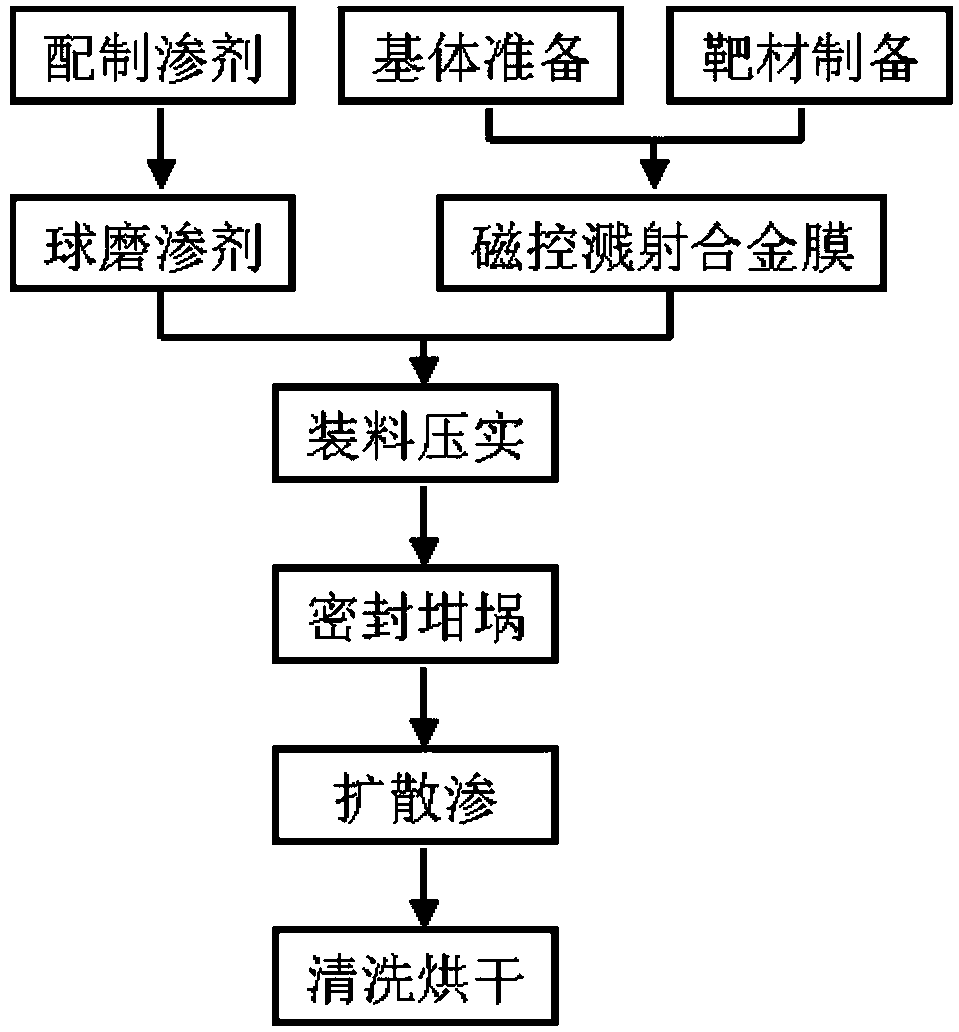

[0040] (1) Prepare the target material: melt the alloy ingot with the nominal composition of 70Ti-10Al-15Nb-5Zr (at.%) in a water-cooled copper crucible high-frequency induction melting furnace, and then cut the alloy ingot into Φ60mm by wire EDM ×3mm disc, and use 240~2000#SiC sandpaper to polish the surface of the target until smooth, ultrasonically clean it in absolute ethanol, and then dry it with cold air for later use; ×7mm×7mm Nb-based ultra-high temperature alloy block sample, the surface is polished to 1000# with water sandpaper, ultrasonically cleaned in anhydrous ethanol, and then dried with cold air for later use; Take Si powder (10wt.%), Y 2 o 3 powder (3wt.%), NaF powder (5wt.%) and Al 2 o 3 powder (82wt.% as a filler); (4) ball milling agent: the ball mill tank containing the agent and balls is installed in a ball mill for ball milling, the ball mill speed is 400r / min, and the ball milling time is 4h; (5) magnetic Controlled sputtering alloy film: place the ...

Embodiment 2

[0043] (1) Prepare the target material: melt an alloy ingot with a nominal composition of 25Ti-8Al-57Nb-10Zr (at.%) in a water-cooled copper crucible high-frequency induction melting furnace, and then cut the alloy ingot into Φ60mm by wire EDM ×3mm disc, and use 240~2000#SiC sandpaper to polish the surface of the target until smooth, ultrasonically clean it in absolute ethanol, and then dry it with cold air for later use; ×7mm×7mm Nb-based ultra-high temperature alloy block sample, the surface is polished to 1000# with water sandpaper, ultrasonically cleaned in anhydrous ethanol, and then dried with cold air for later use; Take Si powder (12wt.%), Y 2 o 3 powder (5wt.%), NaF powder (5wt.%) and Al 2 o 3 powder (78wt.% as a filler); (4) ball milling agent: install the ball mill tank with the agent and balls in the ball mill for ball milling, the speed of the ball mill is 400r / min, and the milling time is 4h; (5) Magnetron sputtering alloy film: place the cleaned substrate al...

Embodiment 3

[0046] (1) Prepare the target material: melt an alloy ingot with a nominal composition of 25Ti-5Al-69Nb-1Zr (at.%) in a water-cooled copper crucible high-frequency induction melting furnace, and then cut the alloy ingot into Φ60mm by wire electric discharge cutting ×3mm disc, and use 240~2000#SiC sandpaper to polish the surface of the target until smooth, ultrasonically clean it in absolute ethanol, and then dry it with cold air for later use; ×7mm×7mm Nb-based ultra-high temperature alloy block sample, the surface is polished to 1000# with water sandpaper, ultrasonically cleaned in anhydrous ethanol, and then dried with cold air for later use; Take Si powder (10wt.%), Y 2 o 3 powder (2wt.%), NaF powder (5wt.%) and Al 2 o 3 powder (87wt.% as filler); (4) ball milling agent: the ball mill tank containing the agent and balls is installed in the ball mill for ball milling, the ball mill speed is 400r / min, and the ball milling time is 4h; (5) magnetic Controlled sputtering all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com