Arc ion plating device

A technology of arc ion and coating device, which is applied in the direction of ion implantation plating, sputtering plating, vacuum evaporation plating, etc., which can solve the problems of high energy input at the discharge spot, reducing the surface finish of the coating, and reducing the performance of the coating. , to achieve the effect of ensuring uniformity and coating rate, reducing the generation of macroscopic particles, and reducing the generation of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

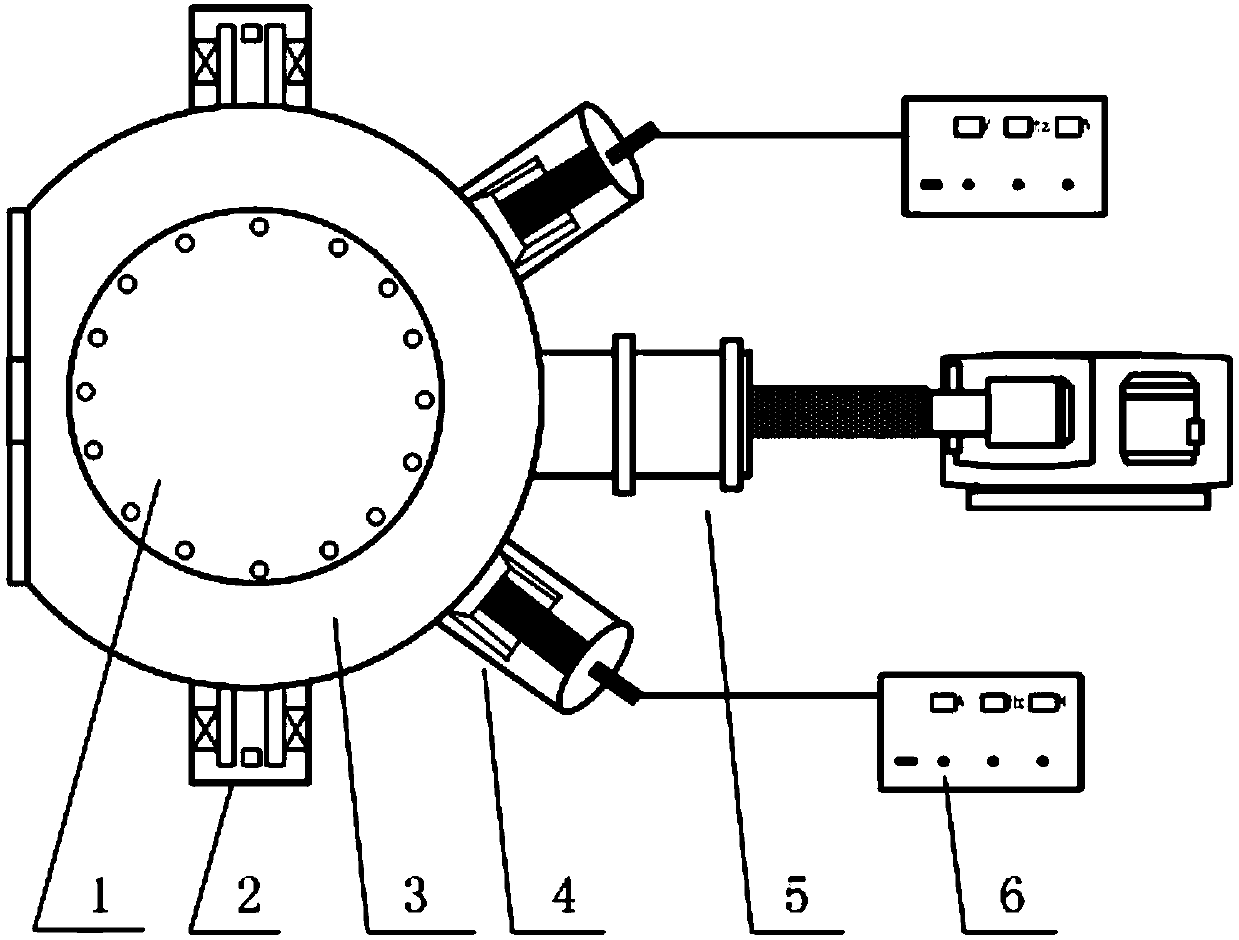

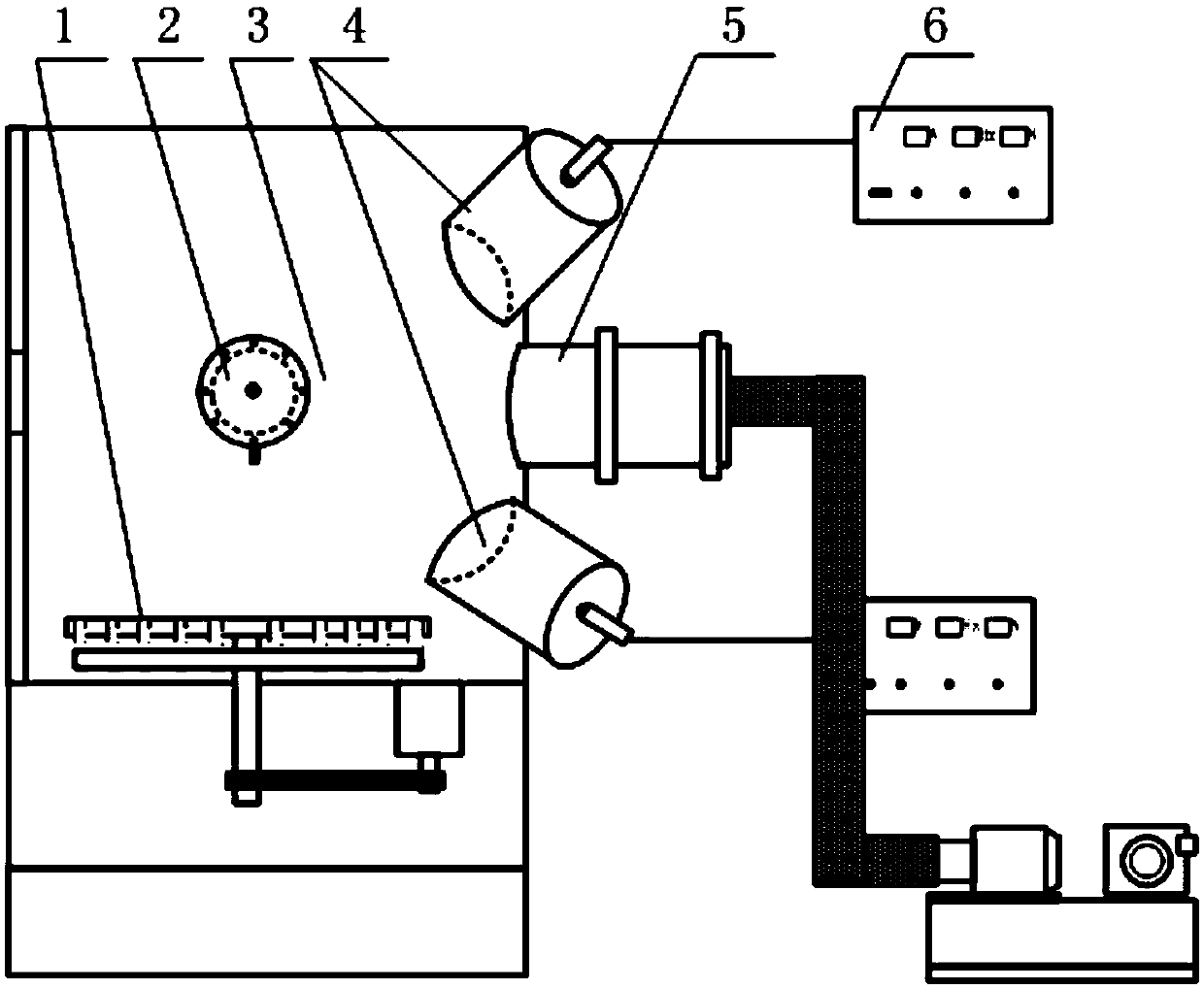

[0028] An arc ion coating device, comprising a vacuum chamber 3, a Hall ion source 2, and an arc ion source 4;

[0029] The vacuum chamber 3 is used as an operating space for workpiece coating, and provides a vacuum system;

[0030] The Hall ion source 2 is provided with a Hall ion source compensator for emitting thermionic enhanced ions, cleaning and activating the surface of the workpiece, and removing impurities on the surface of the workpiece;

[0031] The arc ion source 4 includes two or more arc ion sources 4; it can compensate for the negative impact of the pulse discharge on the coating rate and improve the processing efficiency;

[0032] The arc ion source 4 is powered by a pulse power supply 6 to generate a pulsed arc to excite the target, and is used to generate a large number of target ions in the vacuum chamber 3, which are evenly deposited on the surface of the workpiece to change the surface properties of the workpiece. Not only can the pollution of macroscopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com