Rex rabbit skin tanning method

A kind of tanning and rex rabbit technology, which is applied in the field of rex rabbit skin tanning, can solve the problems of insufficient tensile strength and tear strength, influence on the development of rex rabbit breeding industry, lagging tanning technology, etc., and achieve good extensibility, high-quality appearance, touch and feel plumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

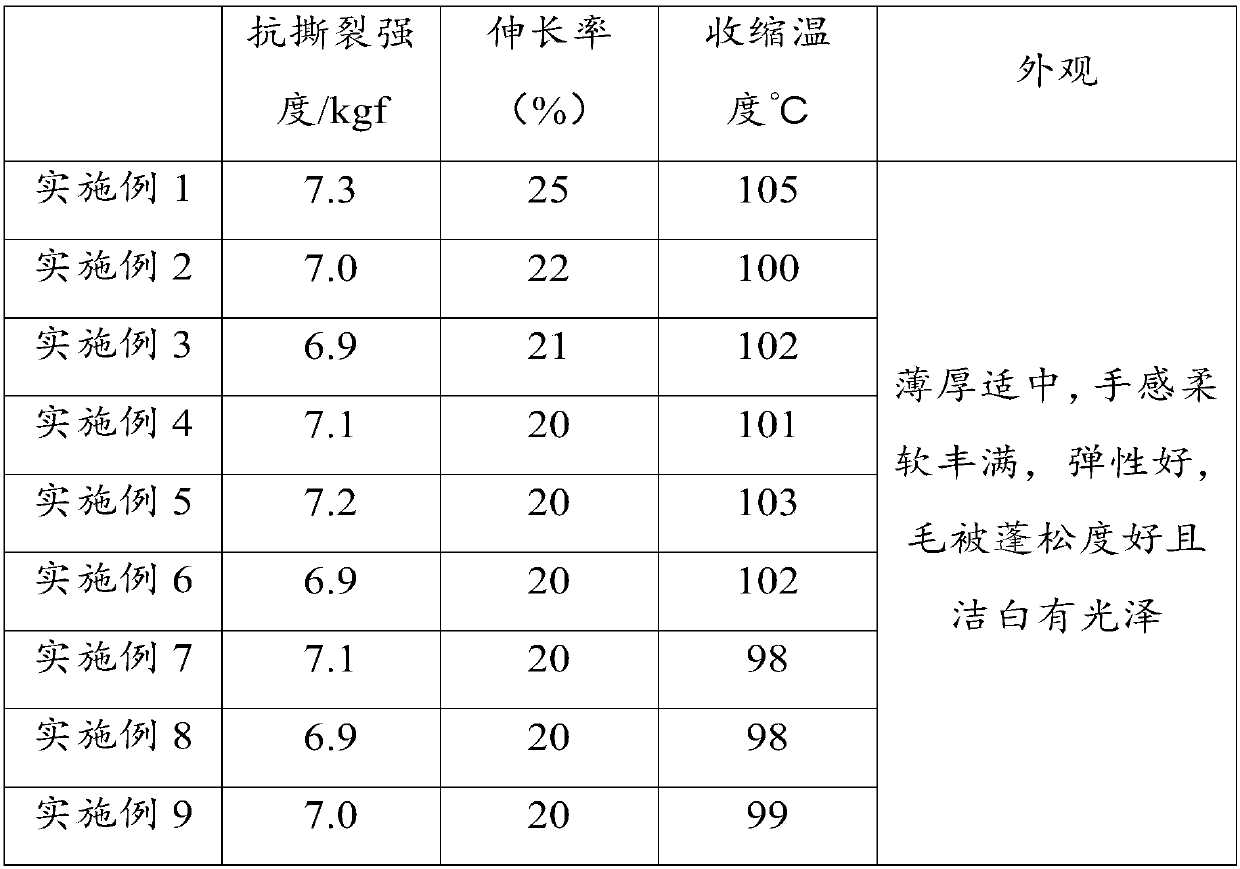

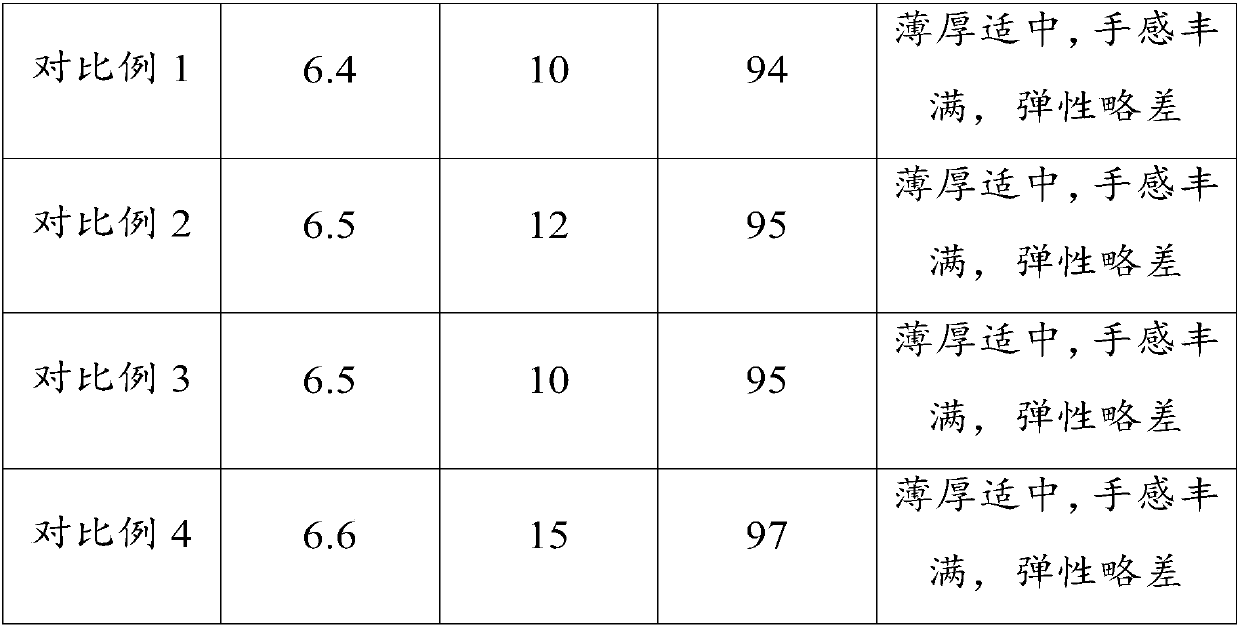

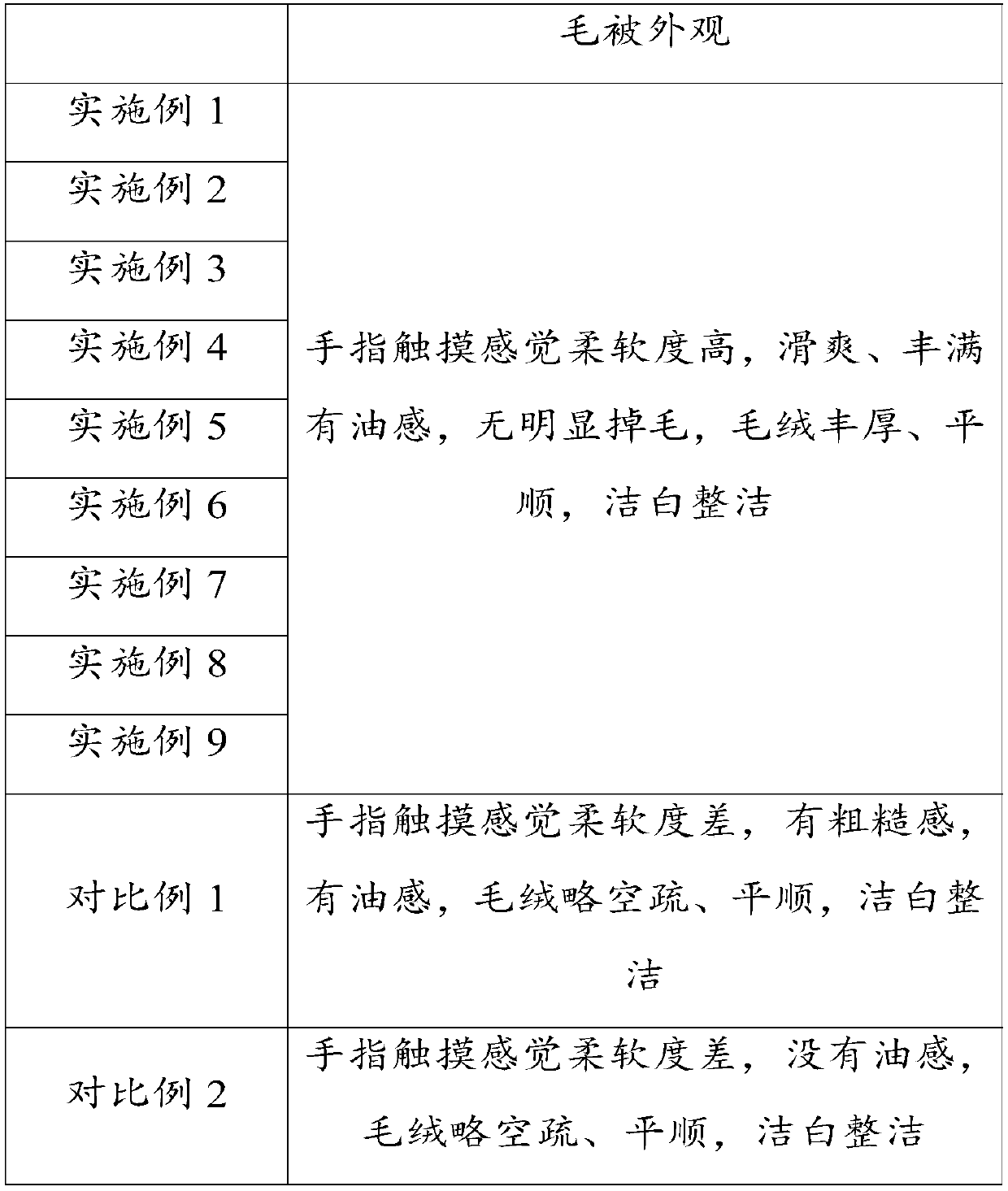

Examples

Embodiment 1

[0059] Processing Rex Rabbit Skin

[0060] The first step, weighing, batching: choose fresh salted rex rabbit skin.

[0061] The second step, pre-processing:

[0062] (1) Immersion

[0063] Soak for 4 hours in an aqueous solution containing 20 / L of salt and 0.5g / L of Ailite wetting agent HAC under the condition of a solid-to-liquid ratio of 1:20; The aqueous solution of agent HAC1.5g / L, bactericide 0.3g / L and sulfuric acid 0.3g / L was intermittently rotated under the condition of solid-liquid ratio of 1:20, overnight.

[0064] (2) Washing

[0065] Wash with an aqueous solution containing 0.5g / L of soda ash, 2g / L of Weiss degreasing agent JA-50 and 0.5g / L of Weiss TS-80 at a temperature of 38°C and a ratio of solid to liquid of 1:20, and the washing time is 60 minute.

[0066] (3) Jieli, remove the meat

[0067] (4) Degreasing

[0068] Rotate for 60 minutes in an aqueous solution containing Eliite degreasing agent H 2g / L and soda ash 0.5g / L, and the temperature is 40°C, t...

Embodiment 2

[0083] The difference from Example 1 is that the compounding ratio of the fatliquoring agent added in the tanning (1) step is different, specifically as follows.

[0084] The first step, weighing, batching: choose fresh salted rex rabbit skin.

[0085] Second step, pretreatment: with embodiment 1.

[0086] The third step, tanning

[0087] (1) Use a solution containing 50g / L of table salt, 1g / L of Wheeler fatliquor FLH and 0.8g / L of Wheeler fatliquor FNP, and rotate for 30 minutes at 35°C and a solid-to-liquid ratio of 1:20;

[0088] (2) with embodiment 1;

[0089] (3) with embodiment 1;

[0090] (4) with embodiment 1;

[0091] The 4th step, post-tanning treatment is the same as embodiment 1.

Embodiment 3

[0093] The difference from Example 1 is that the concentration of the chrome-aluminum tanning agent AC added in the tanning (2) step is different, as follows.

[0094] The first step, weighing, batching: choose fresh salted rex rabbit skin.

[0095] Second step, pretreatment: with embodiment 1.

[0096] The third step, tanning

[0097] (1) with embodiment 1;

[0098] (2) After the first stage of tanning, add 0.5mL / L of formic acid and 8g / L of chrome-aluminum tanning agent AC, and rotate at 35°C for 20 minutes;

[0099] (3) with embodiment 1;

[0100] (4) with embodiment 1;

[0101] The 4th step, post-tanning treatment is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com