Cadmium-arsenic composite polluted soil remediation agent

A soil remediation agent and composite pollution technology, applied in the field of cadmium-arsenic composite polluted soil remediation agents, can solve the problems of lack of cadmium-arsenic composite polluted soil remediation agents, intricate remediation agents, low remediation efficiency, etc., so as to reduce ecological environment risks and restore The effect of low cost and simple application method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Select ferrous sulfate, manganese oxide, fly ash, quicklime, sepiolite, calcium dihydrogen phosphate and wollastonite, weigh according to mass ratio, weigh 30 parts of ferrous sulfate, 10 parts of manganese oxide, 20 parts of pulverized coal Ash, 10 parts of quicklime, 10 parts of sepiolite, 10 parts of calcium dihydrogen phosphate, and 10 parts of wollastonite are uniformly mixed to obtain the cadmium-arsenic composite contaminated soil remediation agent of the present invention.

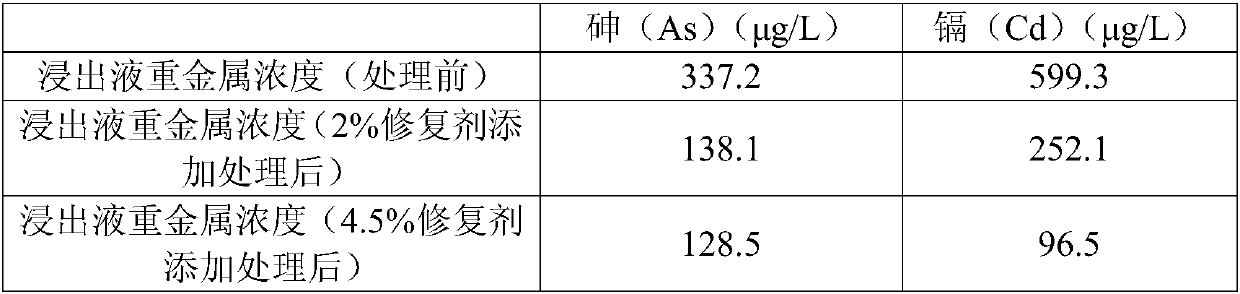

[0032]A heavy metal-contaminated soil in Hengyang, Hunan Province was taken. The soil was a mixture of slag and industrial and domestic waste, and was treated as solid waste. The leaching method refers to the "Solid Waste Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007), and the soil is leached with an overturning oscillator to detect the heavy metal content in the leachate. Compared with the "Groundwater Quality Standard" (GB / T 14848-2017), "Leach Toxicity...

Embodiment 2

[0046] Select hematite, ferrous sulfate, manganese oxide, fly ash, quicklime, sepiolite, calcium dihydrogen phosphate, weigh according to mass ratio, weigh 10 parts of hematite, 20 parts of ferrous sulfate, 10 parts of oxide Manganese, 15 parts of fly ash, 15 parts of quicklime, 15 parts of sepiolite, and 15 parts of calcium dihydrogen phosphate are uniformly mixed to obtain the cadmium-arsenic composite contaminated soil remediation agent of the present invention.

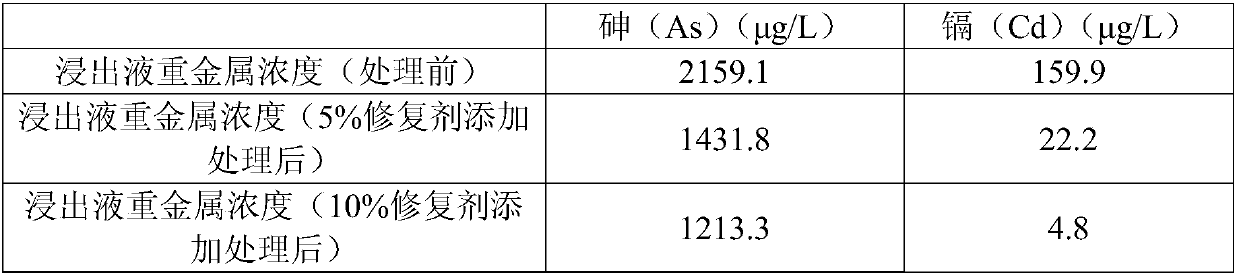

[0047] A heavy metal-contaminated soil in Hunan Province was taken. The soil was mining tailings and was treated as solid waste. The leaching method refers to the "Solid Waste Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007), and the soil is leached with an overturning oscillator to detect the heavy metal content in the leachate. Compared with "Groundwater Quality Standards" (GB / T 14848-2017), "Identification Standards for Hazardous Wastes Leach Toxicity Identification" (GB 5085....

Embodiment 3

[0055] Select hematite, ferrous sulfate, manganese oxide, fly ash, quicklime, sepiolite, calcium dihydrogen phosphate, weigh according to mass ratio, weigh 5 parts of hematite, 30 parts of ferrous sulfate, 10 parts of oxide Manganese, 15 parts of fly ash, 15 parts of quicklime, 10 parts of sepiolite, 10 parts of calcium dihydrogen phosphate, and 5 parts of wollastonite are uniformly mixed to obtain the cadmium-arsenic composite contaminated soil remediation agent of the present invention.

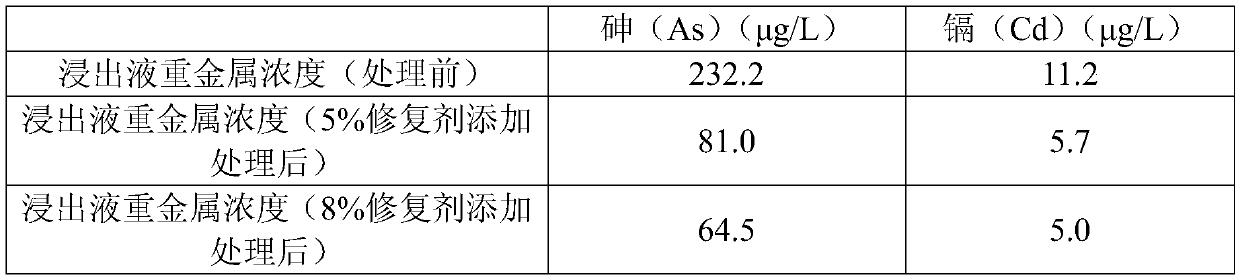

[0056] A certain heavy metal polluted soil in Hunan Province was taken, which was polluted by silver smelting. The leaching method refers to the "Solid Waste Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007), and the soil is leached with an overturning oscillator to detect the heavy metal content in the leachate. Compared with the "Groundwater Quality Standards" (GB / T 14848-2017), "Hazardous Waste Identification Standards Leach Toxicity Identification" (GB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com