Two-component waterborne epoxy zinc-rich primer and preparation method thereof

A water-based epoxy zinc-rich, water-based epoxy technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of brittle coating film and slow drying speed, achieve good adhesion and prevent zinc dust Precipitation, high anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

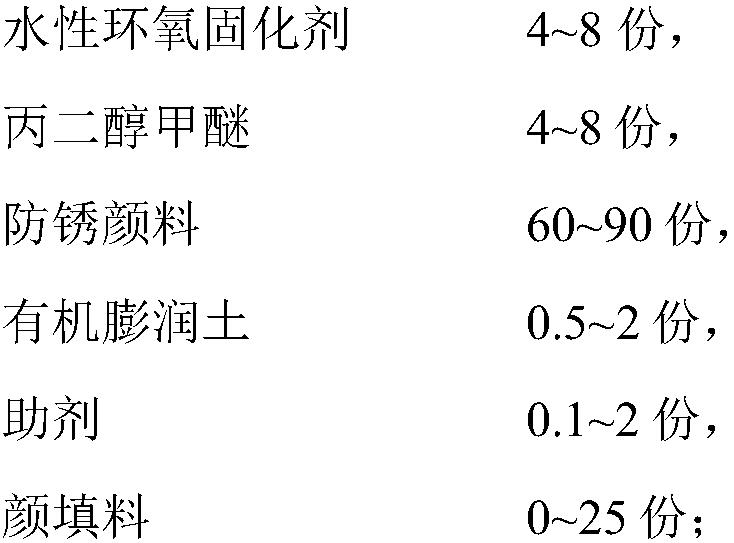

[0038] Based on the production of 100kg, the mass fraction of zinc powder in the dry film of the two-component water-based epoxy zinc-rich primer after drying and film formation is 80%; Table 1 is the parts by weight of each component of the present invention.

[0039] Table 1

[0040]

[0041] In Table 1, part of the zinc powder can be replaced with mica iron oxide according to the needs of different content in the paint film after the zinc powder is dried into a film, as listed in Example 2 and Example 3; BECKOPOX EH 2150 water-based epoxy The curing agent can be replaced by other water-based epoxy curing agents, such as EPIKURETM 8538 water-based epoxy curing agent of HEXION Co., Ltd., as listed in Example 4 and Example 5; EP387 water-based epoxy resin emulsion can be replaced by other water-based Epoxy resin emulsion, such as the EP6520 water-based epoxy resin emulsion of HEXION company, etc., as listed in embodiment 6; 400 order zinc powder can be replaced with zinc po...

Embodiment 2

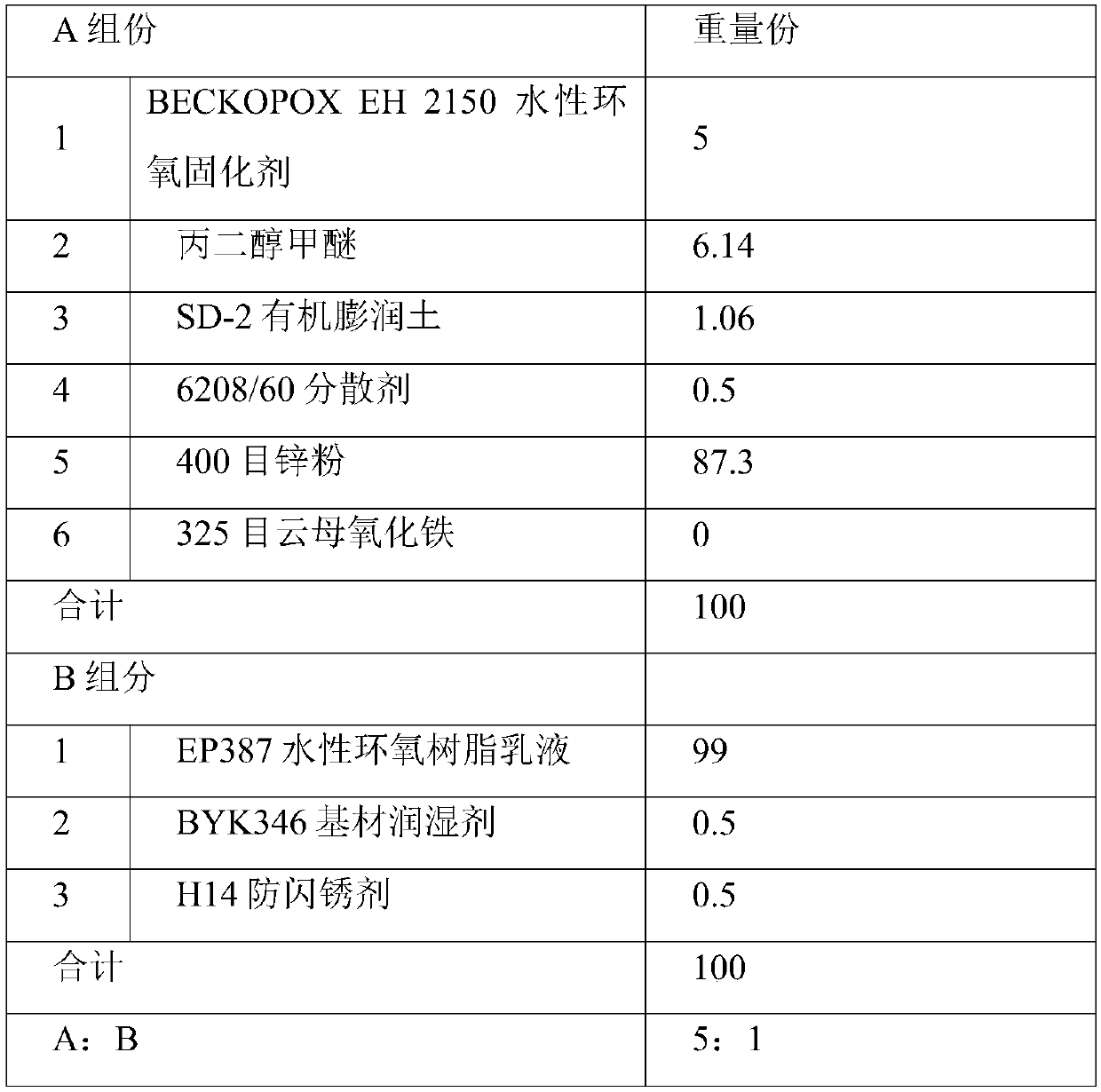

[0055]Based on the production of 100kg, the mass fraction of zinc powder in the dry film after the two-component water-based epoxy zinc-rich primer is dried and formed is 70%; Table 2 is the parts by weight of each component of the present invention.

[0056] Table 2

[0057]

[0058]

[0059] A preparation method of two-component waterborne epoxy zinc-rich primer, comprising the following steps:

[0060] The preparation method of A component is as follows:

[0061] 1) First, accurately weigh the propylene glycol methyl ether and the water-based epoxy curing agent and add them into the stirring tank, and stir slowly at a stirring speed of 600 rpm.

[0062] 2) Accurately weigh the organic bentonite, and slowly add it into the stirring tank during the stirring process.

[0063] 3) After the addition, stir rapidly for 30 minutes to stir evenly, and the stirring speed is 2000 rpm.

[0064] 4) Accurately weigh the auxiliary agent, add it slowly during the stirring process,...

Embodiment 3

[0072] Based on the production of 100kg, the mass fraction of zinc powder in the dry film after the two-component water-based epoxy zinc-rich primer is dried and formed is 60%; Table 3 is the parts by weight of each component of the present invention.

[0073] table 3

[0074]

[0075]

[0076] A preparation method of two-component waterborne epoxy zinc-rich primer, comprising the following steps:

[0077] The preparation method of A component is as follows:

[0078] 1) First, accurately weigh the propylene glycol methyl ether and the water-based epoxy curing agent and add them into the stirring tank, and stir slowly at a stirring speed of 600 rpm.

[0079] 2) Accurately weigh the organic bentonite, and slowly add it into the stirring tank during the stirring process.

[0080] 3) After the addition, stir rapidly for 30 minutes to stir evenly, and the stirring speed is 2000 rpm.

[0081] 4) Accurately weigh the auxiliary agent, add it slowly during the stirring process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com