Outer surface or inner surface conductive type hollow membrane and preparation method thereof

An outer surface and inner surface technology, which is applied in the field of outer surface or inner surface conductive hollow membrane and its preparation, can solve the problems of low automation, high cost and difficulty in preparation, etc., and achieves low production cost, increased electric field density, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing an outer surface conductive hollow film includes the following steps:

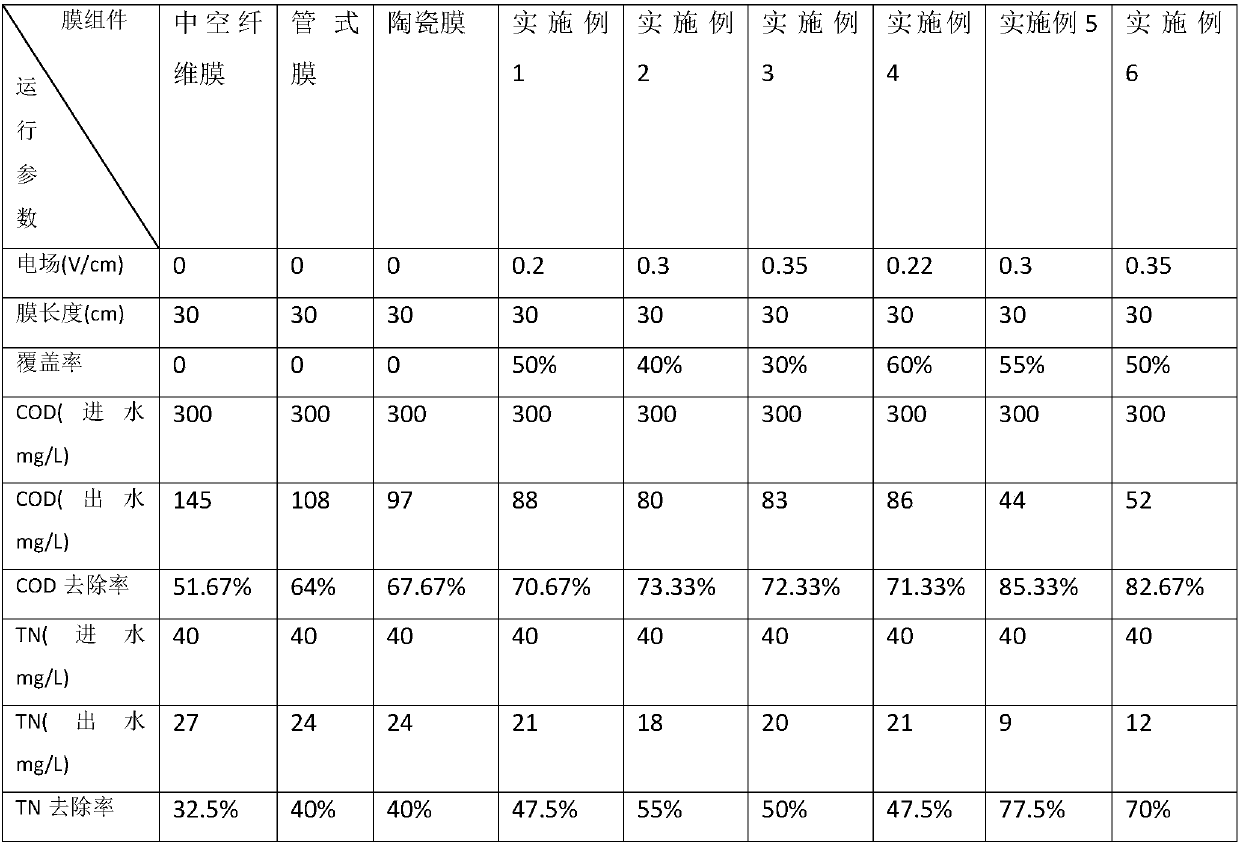

[0031] (1) According to the actual required electric field strength (0.2V / cm) of the outer surface of the hollow membrane, the coverage rate of the surface area of the hollow membrane by the braid as the conductive layer that needs to cover the outer surface of the hollow membrane is obtained by simulation and calculation by the physical field simulation software ( 50%) and the geometric shape or existence form of the braid that can be designed in the physical simulation software under the corresponding electric field intensity

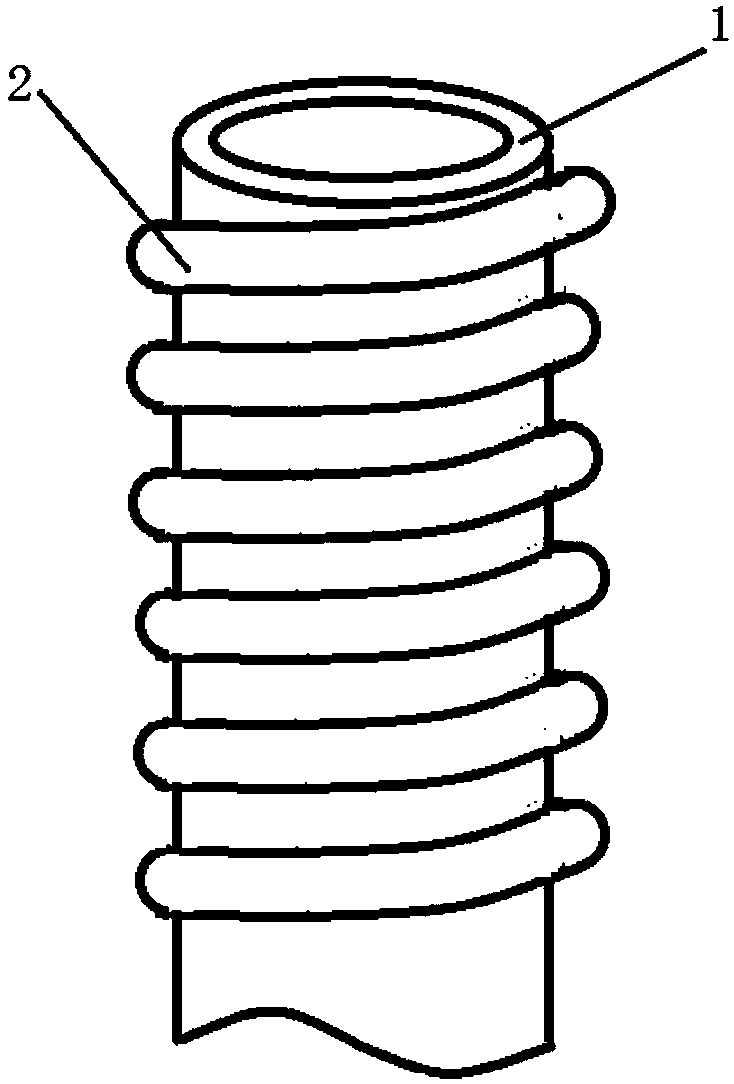

[0032] (2) According to the simulation results, the conductive fiber (carbon fiber T300) is woven on the outer surface of the hollow fiber membrane by a two-dimensional braiding machine. see figure 1 .

Embodiment 2

[0034] A method for preparing an outer surface conductive hollow film includes the following steps:

[0035] (1) According to the actual required electric field intensity (0.3V / cm) of the outer surface of the hollow membrane, the coverage rate of the surface area of the hollow membrane by the braid as the conductive layer that needs to cover the outer surface of the hollow membrane is obtained by simulation and calculation ( 40%) and the geometric shape or existence form of the braid that can be designed in the physical simulation software under the corresponding electric field intensity;

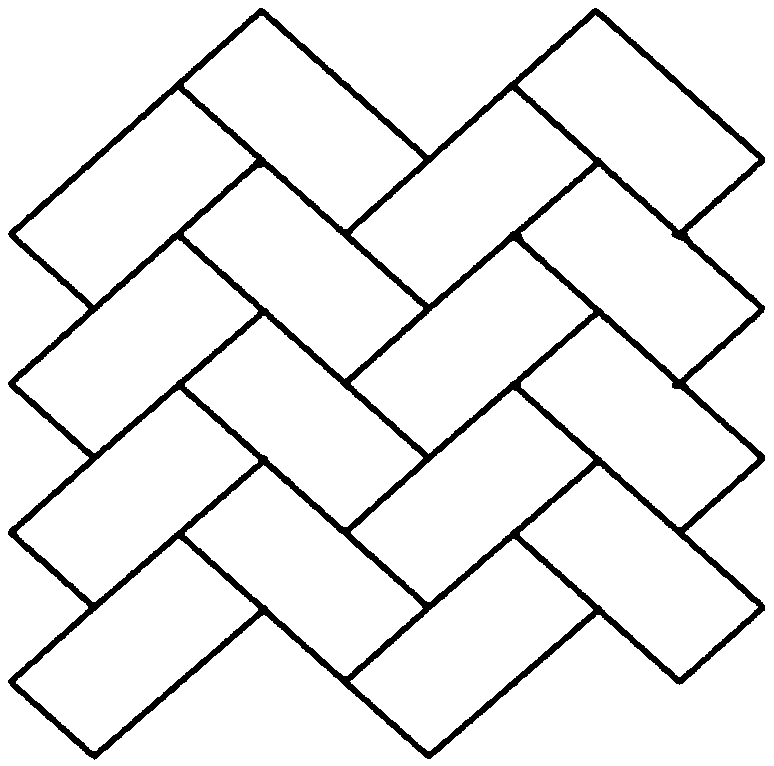

[0036] (2) According to the simulation calculation results, the conductive fiber (polyester) is woven on the outer surface of the tubular membrane by a three-dimensional braiding machine.

Embodiment 3

[0038] A method for preparing an outer surface conductive hollow film includes the following steps:

[0039] (1) According to the actual required electric field intensity (0.35V / cm) of the outer surface of the hollow membrane, the coverage rate of the surface area of the hollow membrane by the braid as the conductive layer that needs to cover the outer surface of the hollow membrane is obtained after simulation and calculation by physical field simulation software ( 30%) and the geometric shape or existence form of the braid that can be designed in the physical simulation software under the corresponding electric field intensity;

[0040] (2) Conductive fibers (lead fibers) are woven on the outer surface of the ceramic tubular membrane by a three-dimensional braiding machine according to the simulation calculation results.

[0041] Experiments have proved that conductive fibers use carbon fiber T700, carbon fiber T800, acrylic fiber, cotton fiber, polypropylene fiber, copper fiber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com