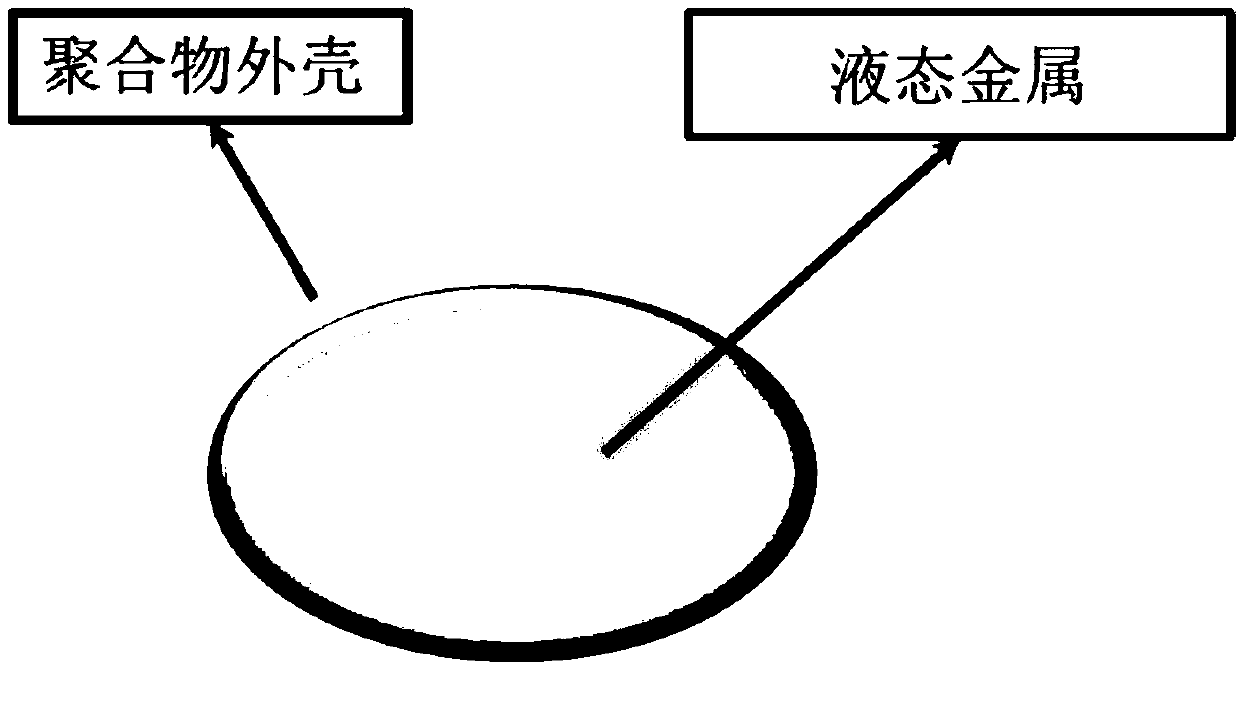

Liquid metal microparticles with core-shell structures and preparation method and application thereof

A liquid metal, core-shell structure technology, applied in metal processing equipment, nanotechnology, transportation and packaging, etc., can solve problems such as easy re-agglomeration, uneven particle size, poor coating effect, etc., to achieve a wide range of application scenarios, Excellent application prospect, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing liquid metal microparticles with a core-shell structure, comprising the steps of:

[0038] 1) Take 250g of tetrahydrofuran and 50g of polyvinyl chloride powder and place them in a 500ml beaker, stir for 30min with a mechanical stirrer, and the stirring speed is 300rpm to make a polymer solution;

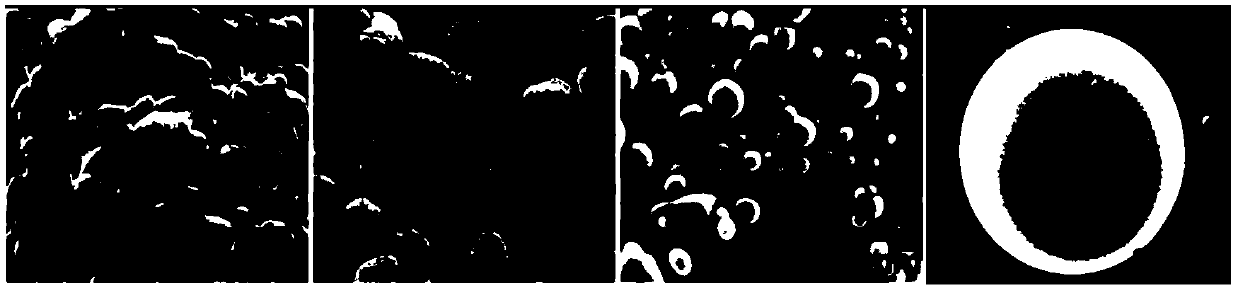

[0039] 2) 20g liquid metal (Ga 75.5 In 24.5 ) into the polymer solution in step 1), placed in a vortex mixer that can spontaneously generate mechanical vibration, and oscillated for 45 minutes;

[0040] 3) Pass the polymer solution mixed with the liquid metal through a filter membrane with a particle size of 150 nm, and extrude it into water. At this time, the polymer solution will solidify when it meets water, thereby covering the liquid metal core, so that liquid metal micro-droplets with a uniform particle size and a core-shell structure can be obtained.

[0041] Basic principle: the addition of polyvinyl chloride not only increases the viscosity o...

Embodiment 2

[0045] A method for preparing liquid metal microparticles with a core-shell structure, specifically comprising the following steps:

[0046] 1) Place 250g of methylpyrrolidone and 50g of polyvinylidene fluoride powder in a 500ml beaker, stir for 30min with a mechanical stirrer at a stirring speed of 300rpm, and obtain a polymer solution;

[0047] 2) 20g liquid metal (Ga 75.5 In 24.5 ) was dropped into the polymer solution prepared in step 1), and stirred for 15 minutes at a speed of 300 rpm using a magnetic stirrer;

[0048] 3) Extrude the above-mentioned organic mixed solution mixed with the liquid metal into water through a filter membrane with a particle size of 300 nm. At this time, the organic mixed solution will solidify when it encounters water, thereby wrapping the liquid metal core, so that liquid metal micro-droplets with a uniform particle size and a core-shell structure can be obtained.

[0049] The diameter of the liquid metal with a core-shell structure prepar...

Embodiment 3

[0051] A method for preparing liquid metal microparticles with a core-shell structure, specifically comprising the following steps:

[0052] 1) Put 250g of N,N-dimethylformamide and 50g of polyethylene powder in a 500ml beaker, stir for 30min with a mechanical stirrer at a stirring speed of 300rpm, and obtain a polymer solution;

[0053] 2) 20g liquid metal Ga 75.5 In 24.5 ) into the polymer solution in step 1), placed in an ultrasonic disperser, and ultrasonicated for 10 minutes in normal mode;

[0054] 3) Extrude the above-mentioned organic mixed solution mixed with liquid metal into water through an alumina template with a particle size of 200 nm. At this time, the organic mixed solution will solidify when it encounters water, thereby wrapping the liquid metal core, so that liquid metal micro-droplets with a uniform particle size and a core-shell structure can be obtained.

[0055] The diameter of the liquid metal microparticles with a core-shell structure prepared in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com