Crystallizer submersed nozzle of beam blank single-point nonequilibrium protective casting and using method

A crystallizer and immersion technology, which is applied in the direction of casting molten material container, casting equipment, metal processing equipment, etc., can solve the problems of slab solidification, many slab defects, and large impact depth, etc., and achieve the reduction of slab defects and reduce The effect of impact depth and improvement of work rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

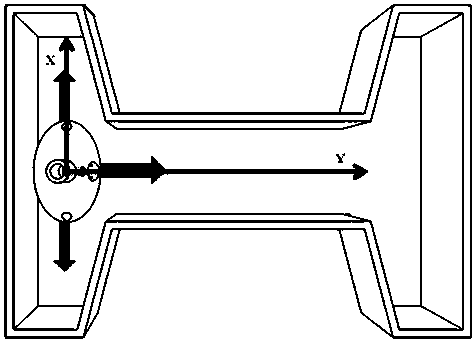

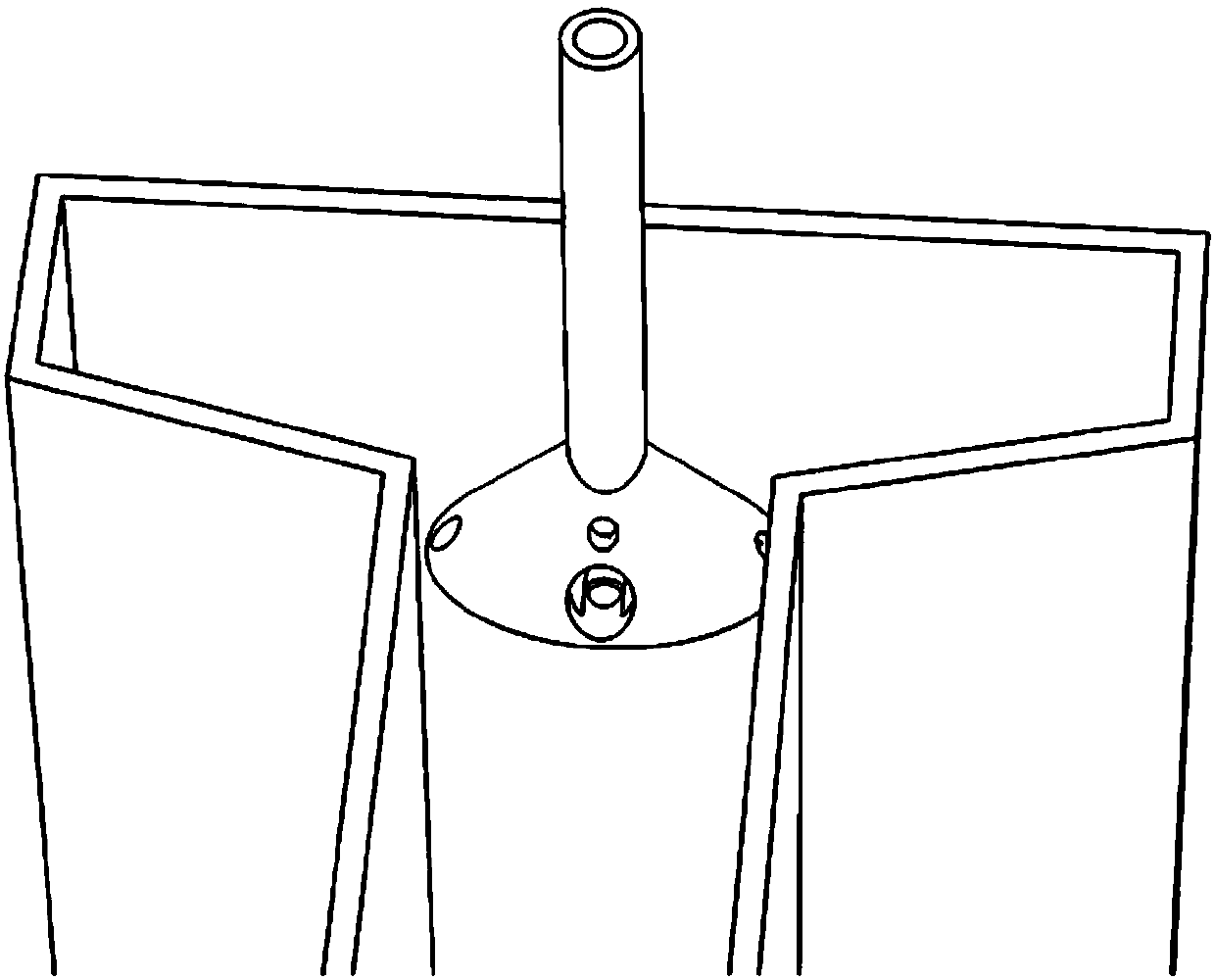

[0048] Please refer to Figure 1 to Figure 7 , a mold submerged nozzle for single-point unbalanced protection casting of special-shaped blanks in this embodiment includes a submerged nozzle body 1, and the submerged nozzle body 1 includes an equal-diameter section 2, a variable-diameter section 3, an equal-diameter section and a variable-diameter section. Diameter joint 4, equal diameter section free end 5 and variable diameter section free end 6; variable diameter section 3 is provided with through hole X7, through hole Y8 and through hole Z9; through hole Y8 includes through hole Y 1 10 and through-hole Y 2 11.

[0049] The cross-sectional shape of the inner side of the equal-diameter section 2 is circular, and the connection between the equal-diameter section 2 and the variable-diameter section 3 constitutes the submerged nozzle body 1. The internal cross-sectional shape of the free end of the section 2 is circular, and the internal cross-sectional shape of the free end 6...

Embodiment 2

[0075] The submerged nozzle structure and usage method of this embodiment are the same as those of Embodiment 1, the difference lies in further explaining the present invention and providing support for the present invention.

[0076] Such as figure 1 with figure 2 As shown, a mold submerged nozzle for single-point unbalanced protection casting of a profiled billet according to the present invention, the insertion point of the submerged nozzle is inside the flange 13 on one side of the profiled billet crystallizer, and the insertion depth is 100mm. The variable diameter section of the submerged nozzle The major axis of the internal section of the free end 6 is parallel to the narrow surface of the crystallizer, and the minor axis of the internal section of the free end 6 of the variable diameter section is perpendicular to the narrow surface of the crystallizer. The X direction is the long axis direction of the inner section of the free end 6 of the variable diameter section...

Embodiment 3

[0083] The submerged nozzle structure and usage method of this embodiment are the same as those of Embodiment 1, the difference lies in further explaining the present invention and providing support for the present invention.

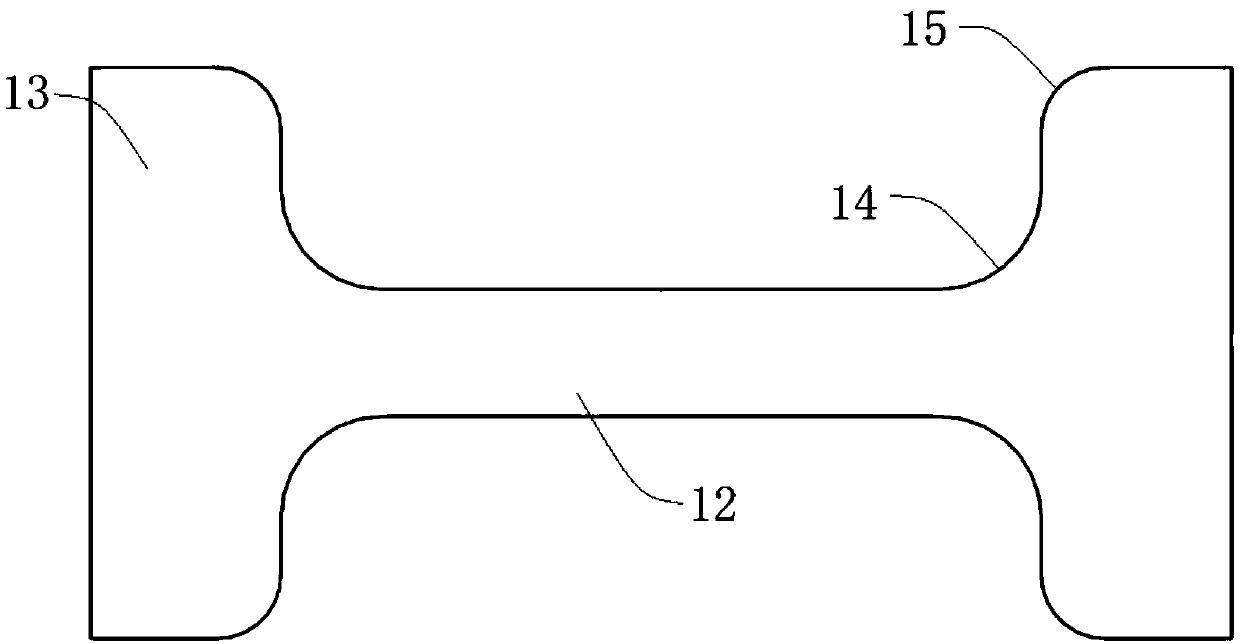

[0084] against image 3 The special-shaped billet shown corresponds to the special-shaped billet crystallizer used in production. This embodiment provides a crystallizer submerged nozzle for single-point unbalanced protection casting of a special-shaped billet. The submerged nozzle is divided into two sections, namely equal-diameter section 2 and The length of variable diameter section 3 and equal diameter section 2 is 490mm, the thickness is 2mm, and the inner diameter is 30mm; the length of variable diameter section 3 is 210mm, the thickness is 3mm, the major axis of the free end is 75mm, and the minor axis of the free end is 37.5mm .

[0085] There are 10 holes in the variable diameter section 3, 2 holes in the X direction, located on both sides of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com