Magnetic/non-magnetic lanthanum carbonate sodium dephosphorization adsorbent and synthetic method thereof

A technology of sodium lanthanum carbonate and phosphorus adsorbent, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems that have not been reported, and achieve simple experimental conditions, small size, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

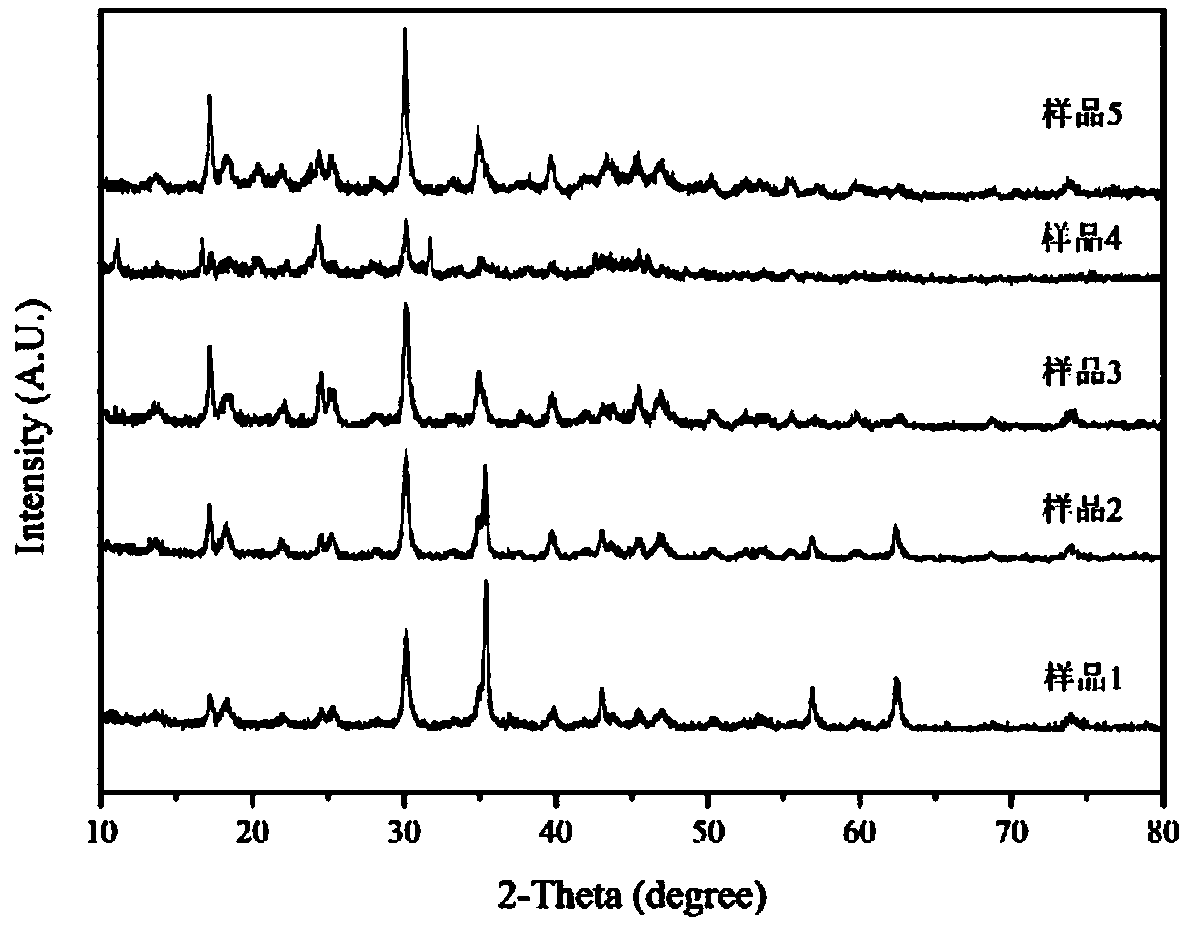

Embodiment 1

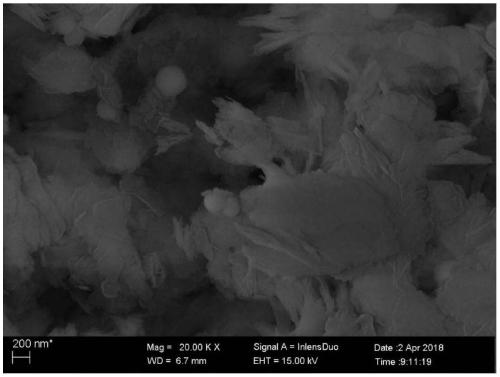

[0031] Weigh 5mmol ferric chloride and 0.5mmol lanthanum chloride and dissolve in 80mL ethylene glycol to form a clear solution. 7.2 g of sodium acetate, 2 g of polyethylene glycol (2000), and 1 g of urea were added to the solution, vigorously mechanically stirred for 30 minutes, and then sealed in a Teflon-lined stainless steel autoclave. Heated at 200°C for 12 hours and cooled to room temperature. After the magnetic separation, the product is washed several times with pure water and ethanol, and vacuum freeze-dried to obtain the magnetic lanthanum sodium carbonate phosphorus-removing adsorbent.

Embodiment 2

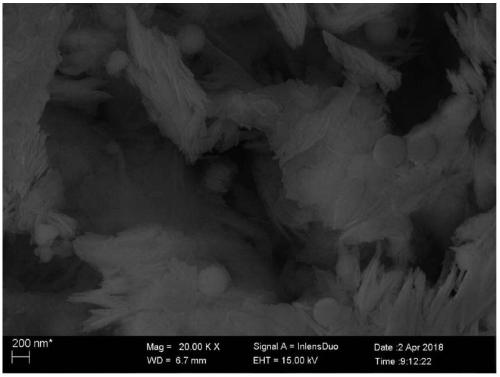

[0033] Weigh 5mmol ferric chloride and 5mmol lanthanum chloride and dissolve in 80mL ethylene glycol to form a clear solution. 7.2 g of sodium citrate, 2 g of polyethylene glycol (500) and 1 g of urea were added to the solution, vigorously magnetically stirred for 30 minutes, and then sealed in a Teflon-lined stainless steel autoclave. Heated at 180°C for 12 hours and cooled to room temperature. After separation by gravity sedimentation, the product was washed several times with pure water and ethanol, and then dried in vacuum at 80°C to obtain the magnetic lanthanum carbonate phosphorus-removing adsorbent.

Embodiment 3

[0035] Weigh 5mmol ferric nitrate and 20mmol lanthanum nitrate and dissolve in 80mL ethylene glycol to form a clear solution. 7.2 g of ethylenediaminetetraacetic acid, 2 g of polyethylene glycol (10000) and 1 g of urea were added to the solution, vigorously magnetically stirred for 30 minutes, and then sealed in a Teflon-lined stainless steel autoclave. Heated at 200°C for 12 hours and cooled to room temperature. After filtration and separation, the product was washed several times with pure water and ethanol, and then vacuum-dried at 60°C to obtain the magnetic lanthanum sodium carbonate phosphorus-removing adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com